Composite reinforcement is a new generation building material that has not yet become widespread. The performance of the product allows it to be used to replace the usual steel bars for reinforcing concrete products, building foundations, port structures, and in construction work on the roads.

Description and production process

First, the rods are impregnated with a polymer composition with curing additives and a reaction accelerator. The excess resin is squeezed out, after which the blanks are shaped. Then the polymer reinforcement is knitted with winding coiling (this is done to improve adhesion to concrete). The products are sent to the oven, where the shell finally solidifies. Then, segments of the required length are formed from them.

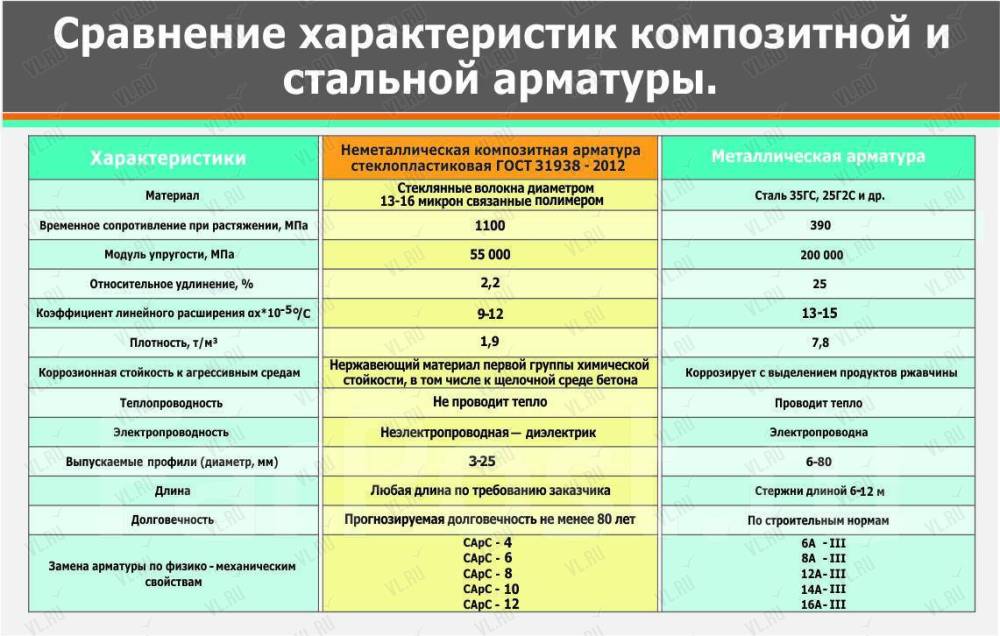

Specifications

Fiberglass reinforcement is characterized by low density (4 times less than that of steel) and, accordingly, light weight. This simplifies the installation process, reduces transport costs and the pressure of the erected structure on the ground.