Construction of aerated concrete can significantly reduce construction times and reduce costs. However, it is important to follow the rules, because the strength of porous materials is noticeably lower than ordinary concrete.

Why reinforce aerated concrete walls

Gas block, if it refers to structural or even structural and thermal insulation materials, withstands rather high bearing loads... It does not need strengthening. In addition, autoclaved concrete practically does not shrink, which protects the walls from cracking.

but the flexural strength of aerated concrete is low... Shrinkage cracks are formed under the influence of shrinkage of the foundation, soil, bending loads of any type. Reinforcement aerated concrete allows you to warn them.

Reinforcement in progress in such cases:

- the building is located in a seismically unstable area;

- the house is worth on a steep slope - strong ground movements are possible here;

- at strong winds and hurricanes in the region;

- if available large openings, the more complex the shape.

The technology of reinforcing gas blocks depends on the degree of reinforcement of the structure and the nature of the material.

What materials are used

Most often, the reinforcement of masonry from aerated concrete blocks is performed using reinforcement - galvanized iron bars required thickness. Diameter the bar depends on the thickness of the wall and is normally 0.02% of the area of the working surface.

For amplification use profiled and smooth reinforcement... The first option can withstand high loads of white, therefore it is used more often. Smooth rods are taken for elements that perform an auxiliary role. For example, when constructing a lattice frame, vertical parts are made from a profiled bar, and horizontal clamps are made from a smooth one.

The material is made from ordinary black steel, since the use of galvanized material significantly increases the cost. Reinforcement in grooves poured with concrete or glue for laying gas blocks. The material protects iron well, therefore, rust does not threaten the fittings.

The overlaps of the reinforcement are tied with a knitting wire.

Mounting method depends on the thickness of the wall and the type of building. The most popular method is double-row reinforcement aerated concrete masonry. But if this is not possible, only 1 rod is laid. Then the diameter of the reinforcement should be larger.

Other materials for reinforcement

In addition to steel rods, other options are used.

- Galvanized mesh - consists of perpendicularly spaced iron rods of small diameter. It is used to reinforce horizontal joints, like a bond between a brick wall and plaster. Take a grid with cell sizes in 50 * 50mm and wire thickness in 3 mm... It does not fit into the grooves, but directly onto the surface of the row, which facilitates installation. Of all types of reinforcement, metal mesh is the most durable material. However, it has a significant disadvantage: iron conducts heat, so the mesh serves cold bridge.

- Basalt mesh - with an elongation at break of not more than 4%. Bars made of basalt fiber material are glued together in knots or fixed with clamps. It weighs less than steel and is absolutely not afraid of moisture. The thermal conductivity of the material is closer to the thermal conductivity of porous concrete, which reduces the risk of cold bridges.Basalt mesh withstands breaking load up to 50 kN / m... And since gas blocks are most afraid of bending stress, this option is perfect for horizontal reinforcement.

- For the reinforcement of aerated concrete blocks, they also take fiberglass reinforcement... The diameter of the bars can be smaller. According to calculations, if a steel bar 10 mm thick is required to strengthen the walls, then the composite reinforcement may have diameter 7-8 mm... The price of the composite is higher, but the durability of such a product is also much greater. Another plus is flexibility, fiberglass does not need to be cut and tied when laying. However, the material is not suitable for rigid reinforcement.

- A good option - perforated metal mounting tape... Its plus is that when reinforcing, you do not need to hammer grooves in bricks. The strip is laid on top of the row and fastened with self-tapping screws, which reduces the consumption of glue. However, the flexural strength of the tape is lower, so it is only suitable for buildings where the load is light.

The number and type of reinforcement depends on the size of the wall, the method of installation, and the height of the block.

Reinforcement technology

Reinforcement of the gas block involves 2 main schemes: vertical and horizontal gain.

The purpose of the vertical way - strengthening the connection between the foundation and the reinforcing interfloor belt. This reinforcement increases the bearing capacity.

Horizontal - according to GOST and SNiP, the procedure is mandatory. This reinforcement ensures the strength of the wall and prevents shrinkage cracks.

Vertical reinforcement

It is often believed that the reinforced concrete frame of a building, the walls of which are filled with aerated blocks, plays the role of reinforcement. This is not the case: the frame takes on additional loads, and the walls remain self-supporting.

The reinforced concrete frame transfers cold, such a house needs additional insulation. While a building made of porous concrete with vertical reinforcement does not need thermal insulation.

Such reinforcement is performed in the following cases:

- the house is located on a steep slope;

- the area is seismically active;

- long beams and other heavy structures were used during construction;

- for additional strengthening of window and door openings, piers.

There are several ways to perform vertical reinforcement.

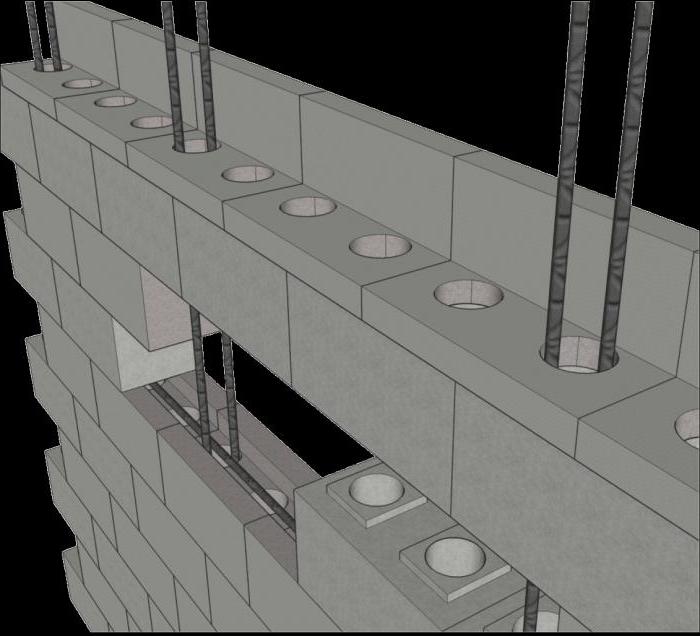

- Using O-boxes - aerated concrete module with a hole through which it is easy to lay the reinforcement. The block can be made by yourself by drilling a hole with a diameter of 150 mm in the brick.

- Single armature strobing - a groove is cut out for a rod in aerated concrete. It is more convenient to make a groove all over the wall at once. Use a saw, jigsaw, screwdriver. To keep the groove along the entire height of the wall even, a board is fixed next to it and used as a guide. Only bar reinforcement is taken.

- If the house is located in a seismically active zone - from 7 points, they construct 3- or 4-bar space frameconnected by transverse clamps. For the main rods and cross-members in the assembled wall, make triangular or rectangular grooves. The minimum bar diameter is 16 mm. Clamps are made of smaller fittings - 6–8 mm. The frame is inserted inside the cut grooves and poured with concrete.

Horizontal reinforcement

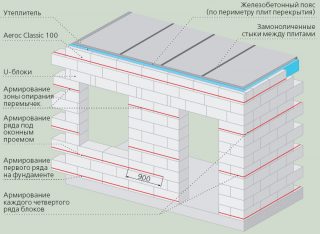

- First row gas blocks is reinforced necessarily over the entire width of the wall span.

- Location on roof or floor support equip a strapping belt to fit all walls. The area of the gables cannot be ruled out.

- Reinforcement of aerated concrete with steel reinforcement is mandatory in windowsill areas... The rods here are brought into the thickness of the wall no less than 50 cm on each side of the vertical edge.

- Fulcrum - the rods are placed under the last row. On both sides of the window opening, they lie 50 cm into the walls.

- If a masonry height between floors more than 3 m, reinforcement is required.

- If a wall length over 6 m, perform horizontal reinforcement in every 4th row from the base.

It is recommended to use steel or basalt mesh for reinforcing load-bearing walls, and fiberglass for partitions.

DIY installation of a reinforcing belt

Reinforcement of walls made of aerated concrete is done by hand. Instructions simple.

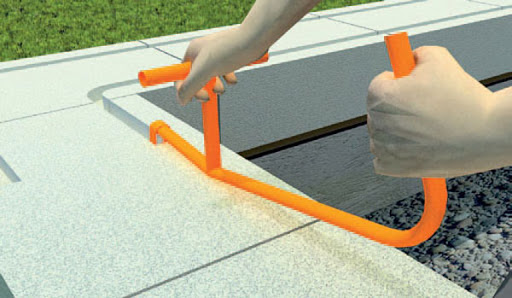

- Since the reinforcing bars are quite thick, grooves are made under them in the bricks - grooves... Groove section 25 * 25mm... Cut it out, stepping back from the edge at least 6 cm.Make strobes manual or electric chaser... The work is simple, as the material is easy to cut and saw.

- The grooves are cleaned of dust with a metal brush. Reinforcing rods are placed in the resulting grooves, bent to the size of the grooves and removed. At the same stage, the corners are adjusted.

- The groove is 2/3 filled with aerated concrete adhesive.

- The rods are again placed in the grooves and sunk in the mixture. It is not necessary to weld the reinforcement, it is enough to lay it with an overlap of 30 cm. It is important that the rods are below the level of the block surface so as not to interfere with the masonry.

- The excess glue is removed, the mixture is applied to the surface of the gated brick. Now you can lay the next row.

- The groove along the entire length of the wall and around the perimeter of the house should be located at the same height. The groove is rounded at the corners.

To strengthen the window lintels, you can lay not an ordinary gas block, but U-shape.

There is no such thing as flexural strength in relation to material. This is a design characteristic. Speaking about the material (foam concrete), we can talk about the compressive strength and tensile strength. When the foundation subsides or from a load, the resulting cracks are called deformation cracks, shrinkage cracks arise from a change in the material itself, as a rule from drying out.