Brick is a versatile building material. However, depending on the manufacturing method, materials used, construction, its purpose is different. White brick is specially designed for the construction of high-rise buildings - up to 9 floors and above.

Material description

Mix for making bricks is made from lime, quartz sand and water... The mass is loaded into molds of appropriate dimensions and configuration. The workpieces are loaded into autoclavewhere the material "matures" under pressure of 10 atm. at a temperature of + 100– + 200 ° С... After autoclaving, the stone is dried and removed from the mold.

To make a batch of material, you will need 6-8 hours... It will take 5-6 days to get the same volume of red clay block.

The method for the manufacture of sand-lime bricks provides a low cost.

Characteristics of white brick

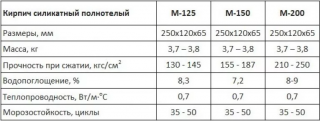

The main physical characteristics:

- thermal conductivity - 0.87 W / m * K, such a building needs to be insulated;

- water absorption - up to 16%, and the same parameter does not depend on the type: corpulent or hollow;

- frost resistance - up to 50 cycles;

- refractoriness - within + 600 ° С;

- mechanical strength - withstands loads from 75 to 350 kg / cm².

The weight of the material depends on the type. Corpulent single with normal specific gravity weighs up to 4 kg, one and a half and double - up to 5.4 kg. Hollow lighter: mass single 3.3 kg, one and a half - 3.8 kg, double - 5-7 kg.

They buy ordinary bricks not by the piece, but in pallets or bundles. The filling of these units of volume depends on the dimensions of the pallet itself and the brick. On average, a pallet holds from 240 to 380 pieces. In a pack - from 480 to 560 pieces.

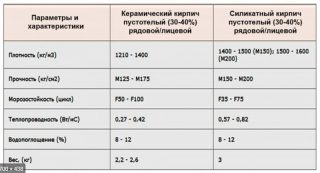

What is the difference from red brick

A silicate block is very different in its properties from a clay block. When choosing a material for construction, this difference should be taken into account.

- Silicate strength is usually higher... At the same time, the weight of the stone is only slightly less than that of clay, so the foundation has to be built the same.

- Frost resistance - clay brick is less porous and absorbs less moisture... For a rainy climate or the sea coast, silicate is not very suitable.You can also use it, but you have to make a lot of effort to protect it from moisture.

- The cost of a silicate block is much lower... At the same time, the masonry technology is the same. Construction is becoming cheaper.

- Coefficient of thermal conductivity - by this parameter clay brick is noticeably superior to white... In mid-latitudes, walls made of ceramic blocks with the same thickness do not need to be insulated.

Although white brick comes in several color options, red looks much more impressive. In addition, silicate absorbs moisture unevenly: streaks, spots of absorbed dirt, efflorescence appear on it. Ceramic retains its attractiveness for much longer.

Types of white silicate bricks

Various types of white stone are produced. Classification in form:

- Corpulent - a solid stone with a very high load-bearing capacity. The material is very strong, durable, but it weighs quite a lot - up to 5 kg.

- Hollow - there are circular indentations inside the body. They are filled with air, which increases the stone's ability to retain heat. When using the hollow version, you can reduce the thickness of the partition.

- single - 150 * 120 * 65 mm;

- one and a half - 250 * 120 * 88 mm;

- double - 250 * 120 * 140 mm.

By appointment also distinguish several categories.

- Private - designed for masonry walls and partitions. Its dimensions and shape may vary slightly. The surface of the sides is not always smooth and beautiful.

- Facial - designed for facade cladding. Its dimensions and configuration are much more accurate. The color is more uniform. Often, such a block is painted, since its own color is not white, but rather a dirty gray.

- Special - stone with special properties, for example, high fire resistance. It is taken when constructing stove floors.

Silicate brick is used for the construction of buildings of different heights, mainly in the southern and middle latitudes and in areas with not the highest humidity. Such material is quite hygroscopic and is afraid of moisture. Since it does not tolerate frosts too well, it is not used for construction in the north.

How does the size of the brick affect the features of the masonry

The size of the stone is chosen based on the characteristics of the project. If the house is private - the walls and partitions are mostly flat - you can take one and a half and double bricks. Due to its larger dimensions, it is easier to stack. However, the main advantage of oversized bricks is that with increasing sizes respectively the strength of the supporting structure also increases.

The size of the blocks has very little effect on the finish. Due to the smaller number of joints, such a surface is easier to level. The composition of the wall does not affect the technology of cladding or plastering.