Block house is a type of lining for interior and exterior wall cladding of the house. The front wall of the board is convex, and the back is flat, grooves and protrusions are formed on the edges of the running pieces for ease of connection. The blockhouse for outdoor use is made in the segment of profiled beams or rounded logs. The finishing layer completely imitates a cobbled or log cabin.

Material description

Lining is also produced from edged boards (in small volumes):

- use four-sided milling machine;

- the workpiece is fed for milling the protrusion;

- the front side is rounded off, grooves are made.

Adjustable cutters with knives are installed on the machine. Their design allows you to make projections and grooves along the length of the board of different widths and depths, changing the settings.

The cost of products from finished boards will be higher. This is explained by the fact that energy and other resources were spent for the production of the board, the cost of which is included in the final price of the block house. The density of such material is lower.

Distinguish types of panels:

- one-break - such products are referred to as the standard type;

- two-break - the molding is distinguished by two bulges along the width of the panel.

For manufacturing use different types of woodto get different shades and colors. More often they take conifers: spruce, pine, cedar, fir, larch. From deciduous trees, birch, linden, aspen are used.

Compared to a log house made of natural wood, the block house has a neater appearance and high quality, with the same characteristics of the natural material.

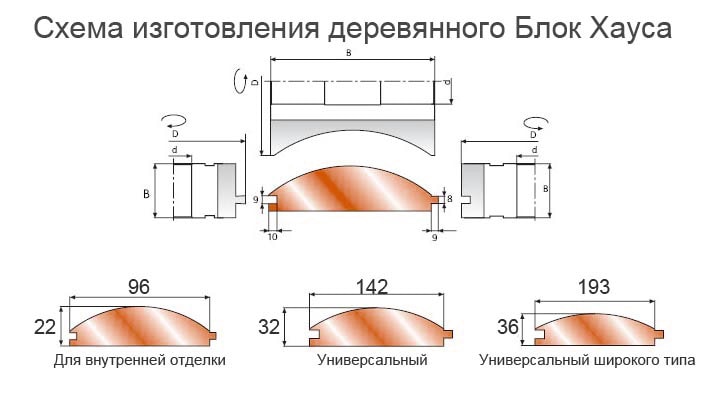

Dimensions, characteristics

For external wall cladding, thicker boards (about 45 mm) are takenthan a block house for interior decoration. A variety of lining is used not only for residential buildings, they are trimmed with gazebos, bath complexes, closed and open balconies, verandas. Width panels consider the useful transverse dimension of the front plane, and thickness measured at the point of maximum thickening, regardless of the cross-sectional shape.

- a narrow profile is produced with a width of 140 mm, while the thickness of the panel is 27 mm;

- wide varieties, respectively, 190 and 45 mm;

- the panels are made from two to six meters in length, so that it is more convenient for users to calculate the material;

- tolerances of deviations: length 1 - 3 mm, width - 0.5 mm;

- the moisture content of the factory board does not exceed 12%, because chamber drying is used for wooden boards.

The number of panels in one cubic meter depends on their dimensions. Suppliers can change the number of boards in 1 m³, while leaving unchanged the square, which such a profile covers.

Manufacturers are guided by GOST 82.42 - 1988 and DIN 68 - 126/86 when releasing a block house, but they also develop their own TU (technical conditions) based on standards. This leads to the fact that profiles can be produced in other sizes. Popular in facade decoration is material 140 mm wide and 27 mm thick.

Varieties and application of block house

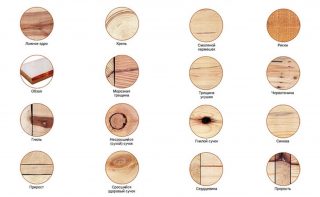

The material is distinguished by varieties... The Western division into classes A, B, C corresponds to varieties in Russia 1,2,3. Additionally, there are categories Premium, Elite, Extra, high quality.

To determine the brand, use various characteristics, which include:

- humidity;

- the presence and number of knots, their condition (dropped out, wobbly, rotten);

- background color, uniformity, presence of darkening;

- fungal lesions (places with blue);

- conformity to size, deformation;

- cracks, wormholes;

- wood species, sawing direction.

- Class A. In production, no more than 1 knot per linear meter is allowed. The knot must hold tight and not fall out. Instead of a knot, there can be 1 resin pocket. Such products are also used for important facilities, used in the decoration of cottages and houses.

- Class B. On a running meter, 2 pockets or knots are allowed, there may be 1 small crack (blind). Blurry spots that do not contrast with the main background are allowed. The material is considered beneficial for the exterior decoration of non-residential buildings.

- Class C. The norms allow up to 4 resin pockets and knots per 1 p / meter. Contrasting areas, stripes are allowed. The lowest quality type of block house has irregularities, cracks, chips, improperly sawed spikes and grooves, and curvature on the surface. It is difficult to mount products because of the fit, therefore the use is limited to the decoration of outbuildings.

Criterias of choice

For exterior walls, material is suitable coniferous... Ideal will be larch, if the developer can afford that cost. In second place is Pine - affordable products at an acceptable cost. The material is not afraid of dampness, it is quite dense. Spruce more often used for interior work, since the strength and density of the panels is low.

When choosing pay attention to factors:

- evenness of the surface, with a minimum number of knots;

- lack of curvature, twists, deformations;

- purchase goods from a trusted supplier who provides a quality certificate for products;

- it is better to take panels of small length (2 - 4 m), and the width can be 140 - 150 mm.

When choosing, take into account material color and shade, if it will not be painted, but only to emphasize the fiber pattern with varnish or stain. On the facade, wooden elements go well with natural stone, red facing bricks.

Rules for cladding a house with a block house

Features of the work:

- vapor barrier is applied to the wall under the frame, the film is overlapped with an overlap of 15 cm;

- put a frame, thermal insulation, wind protection and counter-lattice to ensure the ability to ventilate the insulation;

- boards before installation are treated with protective compounds;

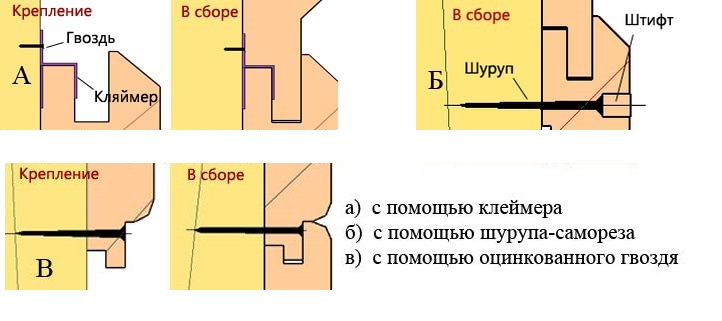

- it is optimal if the hardware is screwed into the base of the spike protrusion, and when the next strip is installed, it is closed with a groove;

- the sheathing is mounted from the bottom up, the panels are connected with a longitudinal tongue in the groove, if necessary, then the fit is made with a wooden or rubber mallet.

How and what to fix

The appearance of the skin layer depends on compliance technologies:

- Above the last panel, leave a gap of at least 5 cm wide so that ventilated gap fresh air got in between the battens. The same gap is left under the lower strip of the lining.

- You need to fix the block house so that the lamellas did not fit tightly, they are installed with a gap of 1 mm, this is necessary for the movement of material with an increase or decrease in street humidity.

- Corners for connection, they are cut at 45 °, if there is no experience of precise work, the joints are closed with wooden corners.

- By lenght the panels are docked using a connecting strip, sometimes they do without it - they putty the seams with a colored compound (the putty is short-lived).

Clammer - this is a galvanized fixing element, which is put into the groove of the lamella on one side, and the other is attached to the lathing. If dismantling is necessary, the layer is easily disassembled, while the panels remain intact.

The nails are driven into a spike at 45 °, the caps are finished before being immersed in the tree. Self-tapping screws provide a secure fit.

What to paint

Almost always the material is processed protective equipment at the production stagebut when installing pay attention to open cutsto be impregnated. Inexpensive block house classes may not be factory processed.

The grain pattern on the surface needs to be emphasized, without painting, for this use:

- water-based, oil-based varnishes;

- impregnations (acrylic, oil, alkyd);

- glazing agents;

- stains.

Choose such paints and varnishes for outdoor use so that withstood the negative influence of the external environment... There are matt and glossy paints. Compositions combined in action simultaneously decorate the surface, protect against moisture. Opaque materials are also used, which include paints based on organic solvents and diluted with water (acrylic, water-based).