Aerated concrete is an interesting modern material that is readily used in private construction. One of the worthy representatives is Bonolit aerated concrete blocks.

What are Bonolit gas blocks

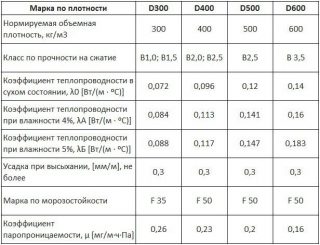

The manufacturer offers gas blocks Bonolit density from 300 to 600 kg / m³. The first option refers to structural and thermal insulation materials. It is noticeably warmer than ordinary concrete, but not as durable. The D600 brand is much stronger. However, the heat capacity of such a stone is insufficient; in middle latitudes, the walls of the building will have to be insulated.

Advantages and disadvantages of the material

- Walls made of such stone weigh less than with standard brickwork. This reduces the load on the foundation and allows a lighter strip base to be built under the house.

- The material is non-flammable and does not support combustion.

- Due to their low density, blocks are made of large sizes. This speeds up and reduces the cost of construction.

- Despite the porosity, the material is durable: a Bonolit aerated concrete house will last at least 50 years, even in difficult operating conditions.

- Aerated concrete is not susceptible to decay, mold, insects or rodents.

- In the production of gas silicate, lime is added to the feedstock. This substance provides the antiseptic properties of stones.

- The exact size and shape of the blocks allows them to be placed on glue. The seam is very thin - up to 3 mm, the appearance of cold bridges is minimal.

disadvantages associated with the presence of voids in the stone.

- Fasteners have to be performed with long anchors or special dowels, since the area of the fasteners inside the stone must be large.

- If the foundation does not have sufficient rigidity, cracks appear on the walls even with reinforcement. Gas blocks are sensitive to bending stress.

- Foam concrete is hygroscopic. For non-autoclaved concrete, this indicator is less, but also significant. The facade needs a protective finish.

The higher the porosity, the higher the thermal insulation properties of the material and the lower the load bearing capacity.

Varieties and specifications

The Bonolit company produces materials necessary for the construction of buildings for any purpose and in any region. They differ in many ways.

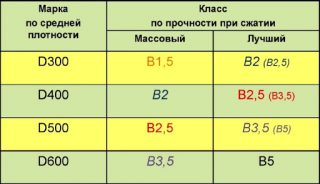

Density classification

- Special blocks of the D600 brand are used for the installation of facades and external walls, withstand a higher load - up to B5. Such concrete does not retain heat very well, but it allows the construction of buildings above 5 floors.

- Structural wall stones - with a density of 500 kg / m³. They are used to build load-bearing walls and internal partitions. The permissible bearing load is less - B3.5.Higher porosity in this case provides lightness without loss of strength.

- Structural and thermal insulation the blocks have a density of 400 kg / m³. They are taken for the construction of houses up to 3 floors high, as well as for the construction of internal partitions. It is allowed to use the material for the construction of higher houses with a reinforced concrete frame.

- Heat insulating blocks of the D300 brand are used for partitions that do not carry heavy loads. The material is used for thermal insulation of the main load-bearing walls, since this addition allows the thickness of the wall to be reduced.

The block sizes determine the purpose. Blocks for masonry walls have a length of 60 cm, a height of 25-50 cm, and a width of up to 25 cm. For partitions, take gas blocks with a smaller width. The bricks for lintels are 50 cm or more thick.

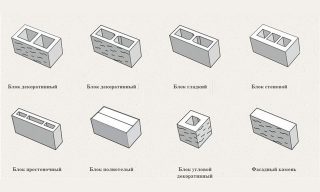

Classification by purpose

For the construction of walls, lintels, partitions, gas blocks with different characteristics are required. It is much easier for the buyer to purchase the necessary products using this classification.

- Wall - designed for the construction of walls. Thanks to the production technology, they are distinguished by very precise dimensions, which makes construction easier and cheaper. The dimensions of the blocks vary, but not too much, since the dimensions are in any case correlated with the required wall thickness, and there are limitations here.

- Partition - are distinguished by their high height, but small thickness - 50, 100 and 150 mm. An interroom partition made of gas blocks is no less durable than that of wall bricks, but much thinner and does not take up so much space. However, this feature must be taken into account when fixing furniture or appliances.

- Reinforced lintels - blocks and beams, reinforced with reinforcement. They are used to reinforce window and door openings. In such places, reinforcement is mandatory and under any circumstances. It is much more convenient to take ready-made beams.

- Stone insulation - a somewhat conventional name for a brick made from the most porous concrete - grade D200. The dimensions, or rather the thickness of the block, depend on the degree of required insulation - 50, 100, 300 mm.

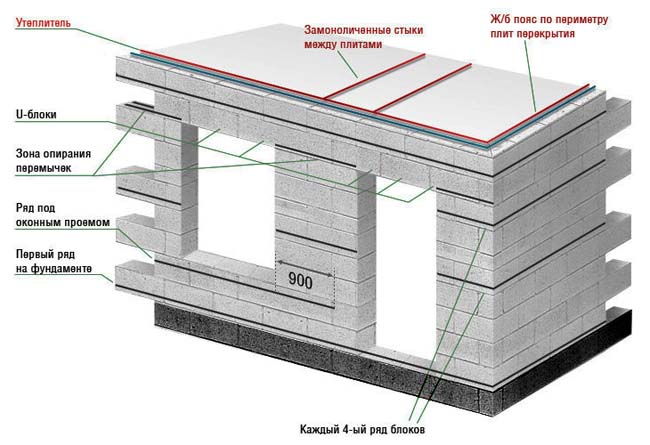

- Foam blocks are also available for internal hidden structures and for the construction of a monolithic belt... They are distinguished by their U-shape. The elements are made of the most durable concrete - the D600 brand, and of increased frost resistance.

There are also tongue-and-groove models - with protrusions and grooves at the ends. Such a surface makes it possible to do without gluing vertical joints.

Specifications

- strength corresponds to the brand, the permissible load ranges from 2 to 5 MPa;

- thermal conductivity is also determined by porosity, but does not exceed 0.14 W / sq. m * K;

- frost resistance - versions are produced that can withstand from 15 to 100 full cycles of freezing and defrosting;

- weight products depends on the density and dimensions, on average does not exceed 25 kg.

- hygroscopicity depends not so much on porosity as on the manufacturing method, and varies from 6 to 16%.

Material specifications are shown on the packaging. You need to familiarize yourself with them.

Features of use in construction

Bonolit gas blocks are lightweight and durable. However, the porous structure determines a number of rules that must be followed when constructing walls. Recommendations for construction load-bearing and interior walls are somewhat different.

- The foundation for foam concrete must be waterproofed. Otherwise, the walls will draw moisture from the basement. Roofing material, waterproofing, mastic are used. The surface of the foundation is pre-leveled. Height differences of more than 2 cm are not allowed.

- The corner blocks are laid first. A cord is pulled between them and a wall is laid out on it.

- The first row is placed on a cement mortar. It helps to compensate for unevenness. The rest of the masonry is done with special glue.

- The first row is reinforced without fail. If the wall reaches a length of more than 6 m, the reinforcement is laid in every 4th row.It is also necessary to reinforce the window sill, support points and the last row under the floors.

- Interior partitions can be laid either on the foundation strip or directly on the cement floor. The first 3 rows of the wall are reinforced, just like the last 3.

- The partition must be fixed to the load-bearing wall. Fastening is carried out by driving metal crutches into the bearing wall.

- The partition is not attached to the ceiling, on the contrary, usually there is a gap between it and the ceiling, which must be sealed with polyurethane foam.

Aerated concrete is hygroscopic, so it is advisable to plaster the outer and inner walls of the house.