Plywood is one of the most common wood-based materials used in construction. Since the base is wood, it is sensitive to moisture and steam. Depending on the operating conditions, plywood must be protected with different means.

What is plywood

In solid wood, the fibers are oriented approximately in the same direction. When assembling a plywood sheet, the sections are laid so that the fibers were directed perpendicular to each other... As a result, the plate turns out to be withsink simultaneously to pressure, bend and stretch.

Most often, the raw material is coniferous wood - pine, spruce and birch... Plywood can be made from 1 material and from different materials.

Plywood easy to handle: cut, sawn, bend. This makes it the best material for making furniture, crafts and DIY upholstery. The appearance is also very attractive: plywood is made of veneer, and more expensive and beautiful wood is often chosen for the top layer of the board.

What is the peculiarity of moisture resistant plywood

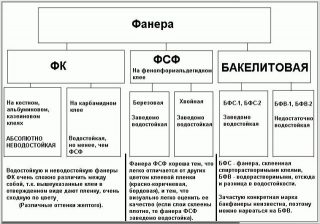

Plywood water resistance is determined by the adhesivewhich is used during assembly. The material created on the basis of albumincasein or urea glue does not differ in resistance to moisture. But if water-insoluble mixtures are used, the result is different.

- FSF - phenol-formaldehyde glue is used. The water resistance of the material is sufficient to be used in the construction of garden furniture and other outdoor structures. In the apartment it is used for finishing bathrooms, if the emission class does not exceed E1.

- FKM - glue based on melamine resins is used here.

- BS - bakelite glue is used in the manufacture. This plywood is called aviation plywood for its extraordinary strength and low weight. It does not rot, does not swell, and is absolutely water resistant. However, the material is expensive and is not used in construction.

- FB - wood cuts are impregnated with bakelite varnish before gluing. Such material is maximally resistant to water and steam, aggressive environments. It is used even in the tropics and under water.

It is unprofitable to buy waterproof plywood for finishing a balcony or kitchen. It is easier and cheaper to purchase a medium-strength material and impregnate it with a suitable product.

Processing facilities

Various products are used as water-repellent impregnations for plywood. Their main task is to create a thin waterproof film on the surface. The latter is most often transparent, since the structure of the tree is beautiful enough - it is usually preserved.

Drying oil

For plywood processing, drying oil is heated to a temperature of 55 ° C. Apply liquid with a paint brush, be sure to cover the ends.

The protective layer can be blow-dried or left to dry naturally.

If the material is used in damp rooms or outdoors, it is recommended to coat the plywood with linseed oil twice.

Fiberglass

The same can be done using calico or calico, as well as nitro paint... In this case, the plywood is first coated with linseed oil, and then with a layer of liquid paint as a primer. After drying, a layer of nitro putty is applied, and then a cloth is applied and pressed firmly to the surface. The last step is to apply another layer of liquid nitro paint.

Nitro paint

When painting, it is recommended to dilute nitro enamel with a solvent to get a really thin layer. One layer is enough to protect the material.

Wax

Sometimes use oil socks... Such a mixture does not so much form a film as it impregnates the top layer of plywood. It is more stable and durable, but also needs updating.

PVA

After that, the plywood is turned over and processed from the reverse side. The work is carried out in a dry, warm room, since water-repellent impregnation for plywood at low temperatures is impossible.

Epoxy glue can be used for impregnation. In this case, each applied layer must be warmed up and dried with a hairdryer.

How to choose impregnation

Glue, paint or varnish are selected taking into account the conditions of use of the processed material.

- For interior work odorless, quick-drying formulations are suitable. At the same time, the water resistance may not be too great, as, for example, with acrylic paint, varnish, stain. For residential premises, this level of protection is sufficient.

- For rooms with high humidity more powerful means of protection are used: impregnation with PVA glue, oil paints, hot drying oil.

- For external work take oil paints, special facade coatings, as they are maximally resistant to water.

Waterproof mixtures do not increase the fire safety of the material. This requires flame retardant paints.

How to soak with your own hands

It is not difficult to process plywood for moisture resistance. The work requires only accuracy and some time.

Surface preparation

Sheets are cleaned of dust and dirt... Wipe with a damp sponge if necessary. If the plywood is of a high class or is laminated, = no additional processing is needed. If it is a normal material, before using impregnation the surface is polished... To do this, use fine-grain sandpaper.

After grinding, the slabs are wiped again, if necessary, left to dry. Can treat the sheet with an antisepticto increase resistance to mold and mildew.

Safety engineering

During work, some rules should be followed.

- Different formulations dry at different times... The dates are indicated on the package. It is necessary to withstand them. If a second layer of glue, for example, or paint is applied to the not yet dried first layer, it hardens unevenly. The result is a surface with streaks and bubbles.

- When working with toxic compounds or with a strong odor work is performed in a respirator and goggles. It is also recommended to wear gloves and an apron.

- Stay in the room is not allowedwhere processing is taking place, pets and children.

- The recommended number of layers and processing conditions are indicated in the instructions. It should be studied and followed.

Impregnation is carried out in a warm room - this is a prerequisite. You can work in an open area during the hot season.

Carrying out works

The treatment of plywood from moisture and decay is carried out according to different schemes, depending on the chosen product. General rules:

- Liquid mixtures are applied by spray... Viscous compounds are applied with a brush or roller. The mixture with wax is rubbed over the surface of the sheet.

- Apply the product along the direction of the wood grain... So it is better absorbed.

- Impregnation takes some time. The second layer is applied only after the first one is completely dry.... If the product creates a film on the surface, like nitro paint, 2-3 coats are sufficient. If the composition exactly impregnates the plywood, more layers are applied, achieving deep penetration of the mixture into the material.

If, before impregnation, small defects are found, such as cracks and chips, they are sealed with a putty, and then primed.

How to process the ends

In order for the sheet to be completely protected from moisture, not only the surface is treated, but also the ends. For this use narrow soft brushes... The impregnation is repeated as many times as the surface is treated.

If a wall or floor is protected with a moisture-resistant agent, the ends remain inaccessible. In this case the joints between the plates are sealed with masking tapeand then impregnate or paint the floor or wall.

Further exploitation

The service life of the protective mixture is rather short. Under the influence of dampness, ultraviolet radiation, mechanical factors, the protective layer is abraded. It needs to be updated periodically. The repair time depends on the nature of the composition used.

A layer of varnish or wax is renewed... If worn out or damaged a layer of paint or glue impregnation, you need to act differently. It is not enough just to paint over the crack, because moisture has already got under the damaged layers. Such a site cleaned with sandpaper, and then twice treated with a moisture-resistant agent.