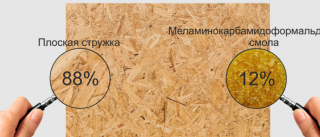

Lightweight frame buildings are rarely clad with heavy materials such as clinker or fiber cement panels. However, plastic siding is not recommended for their finishing - it does not let in steam. The ideal option is chipboards.

Facade decoration with OSB plates

Release 4 types of material:

- OSB-1 - designed for indoor use and is not resistant to moisture;

- OSB-2 - durable and resistant to moisture, used for the construction of internal partitions;

- OSB-3 - suitable for outdoor use, insensitive to moisture;

- OSB-4 - heavy-duty version, used in the construction of load-bearing walls and roofs.

The moisture resistance of the material depends on the type of adhesive used, lamination or impregnation.

The service life is determined by weather conditions: the amount of precipitation and the frequency of frost.