Gas blocks are a high-tech building material with certain physical and chemical properties. When erecting buildings, it must be precisely laid and sawed. Many hand and electric tools have been developed for working with foam concrete.

Material features

Aerated concrete is made from a mixture of Portland cement and sand, into which reagents are poured to form foam. Most often, ordinary powdered aluminum, aluminum pastes and powders are used for this. As a result of their reaction with Portland cement, small air bubbles are evenly distributed over the structure of the solution.

Depending on the density, aerated concrete blocks are subdivided into grades:

- D300-D500 - thermal insulation building material.

- D500-D900 - structural and thermal insulation material.

- D1000 – D1200 - building blocks.

The compressive strength of aerated concrete is 1.5 - 3.5 kgf / cm². In a dry state, the thermal conductivity of aerated concrete is 0.12 W / m ° C. The density of this material is 400 - 1200 kg / m³.

The enclosing and supporting structures, erected from aerated concrete, belong to the I and II class of fire safety.

This material is environmentally friendly, since no toxic substances are released from it during operation.

Due to its good performance characteristics, aerated concrete is widely used in low-rise construction.

Tools for cutting aerated concrete in length and width

It is easy to work with aerated concrete. You can cut the gas block with hand or electric saws, which allows you to make various structural elements of buildings and structures of any geometry from them.

For cutting foam concrete are used:

- band saws;

- special hand saws;

- reciprocating saws;

- chain saws;

- additional devices.

Band-saw

The belt-type machine for cutting gas blocks is a professional high-performance equipment. Allows you to cut aerated concrete blocks into narrow parts. They are not used for the construction of individual houses, but they are often used in the construction of large commercial or industrial facilities.

The machine is divided into upper and lower parts, between which there is a working area where blocks are sawn.

The working units have wheels on shafts driven by an electric motor. The working blade is stretched between them in almost the same way as the chain.

One part of the canvas is placed in the machine, so it is not visible, and the second passes through the working area - an iron plate with markings.

The machine has two buttons for turning it on and off.

An efficient dust extraction system is provided, which allows you to create the necessary conditions for long and continuous operation.

Pros:

- Has maximum performance. The material is cut very quickly.

- It has an extremely simple design, so you can service it yourself.

- Allows you to install electric motors of the required power.

- Can cut thick blocks easily.

- The movement of the work unit even allows for circular cutouts.

- Thanks to the guide system, precise cutting lines are obtained.

Minuses:

- Does not allow cutting holes.

- The work requires a professional who is well aware of safety precautions, as the cutting belt can cause fatal injury.

Due to its large dimensions, a spacious truck is needed to transport the banding machine.

How to saw with a hacksaw

Due to its low density, it is possible to cut aerated concrete block with hand saws with a special cutting edge. It is advisable to use this tool if the amount of work is small and the configuration of the elements being erected is simple.

It is advantageous to use this saw due to its low cost. She can work at a height where it is extremely difficult and often impossible to climb with other equipment. This allows the master to quickly perform the necessary operations, since the hacksaw is lightweight and always at hand.

Among the shortcomings, it is worth highlighting the low accuracy of the cut. This problem is solved by cutting along the guide frame, which is installed on the block. This will make the cut smoother.

Basically, a manual hacksaw is used to saw aerated concrete at home.

When choosing it, the following aspects must be taken into account:

- cutting technology;

- density of aerated concrete;

- temperature and humidity at the facility.

Reciprocating saw

It is effective for cutting a gas block, therefore, it can significantly save time and effort. The tool is inexpensive, so even for building your own home, the purchase will be justified.

The reciprocating saw cuts the material using the fast rotary-translational movements of the replaceable blade. The length of the cutting blade can be different, but for comfortable work, experts recommend using blades longer than the thickness of the block.

Pros:

- Exact cut.

- Great performance.

- Allows you to make closed cuts.

- You can make grooves for electrical wiring and fittings.

Minuses:

- It costs an average of 10,000 - 20,000 rubles.

- High-quality canvases cost about 1,500 rubles, and they can not always be found in stores.

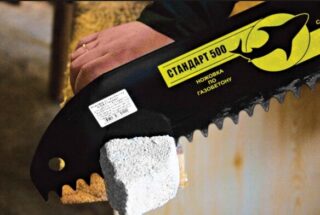

Chain saw

This tool allows you to cut a gas silicate block and cut blind holes or slots of various shapes in it. It is considered versatile because it is able to cut various building materials.

The advantage of the saw is that it cuts material by rotating the cutting edge in one direction. This allows you to effectively remove sawdust from the working area, while the rod does not hit the material during the blind cut, which reduces the risk of saw jamming.

U-grooves can be cut with a power tool.

Pros:

- Blocks can be cut right into the masonry.

- It is possible to work in many positions (sawing at an angle, at a height, etc.).

- Complete with guide rails for a straight saw.

Minuses:

- The chain on wood that comes with the complete set allows you to cut aerated concrete, but it quickly becomes blunt, so you have to buy a chain with a victorious spray at a price of about 2,000 rubles.

- The saw itself costs from 10,000 rubles.

- As a result of prolonged operation, it gets very hot, which leads to the stretching of the chain. If one link at a time is not removed from the chain in a timely manner, it may come off. Because of this, you need to periodically let it cool down.

- Saw sprockets wear out quickly. They are not expensive, but they take a long time to replace.

- The kerf is very thick, so more mortar needs to be placed between the blocks.

The electric chain saw is a traumatic tool, since the cutting mechanism is open. Many workers are injured as a result of working with it every year.

Additional accessories for cutting aerated concrete

For certain types of work, use:

- A special plane - a grater with an iron sole and a handle. Allows precise alignment of sawn blocks, making them easier to stack.

- Manual wall chaser is a bent iron pipe with a handle that allows you to make a rounded groove on the surface of blocks for laying fittings, pipes, etc. (after the construction of the building).

- Electric wall chaser - looks like a circular saw, but it uses two blades. Due to the precise mechanism for adjusting the depth of the saw, it is possible to make the necessary slots for the strobes. They can also be cut with a grinder.

- Crowns - it is advisable to buy for concrete, with a strong victorious cutting solder.Allows making holes in ceilings and walls for laying ventilation ducts, mounting sockets, etc.

- Corner - allows you to control the cutting process.

In order for the cutting of aerated concrete to be accurate, it is better to make your own miter box - a wooden rectangular structure in the shape of two letters P, fixed on the platform with corners. The block should fit inside these letters without any problems. There must be a normal clearance between them to make the cut. The clearance should allow the saw to move freely, but not sideways. In the plane of the platform, it should be larger than on the sides. This will allow waste to flow there during operation.

Safety precautions when cutting aerated concrete oblige to use certain technologies, taking into account the tool used, as well as overalls (suit, boots or boots, gloves or mittens) and personal protective equipment (respirators, masks or goggles).