Cement particle board is an increasingly popular building material suitable for a wide range of applications. DSP cutting is a mandatory technological operation that is carried out at the place of work. In order to avoid mistakes, cut with a minimum amount of waste and not get a lot of dust and dirt, it is necessary to choose the right tool and work methods.

What is DSP and the nuances of use

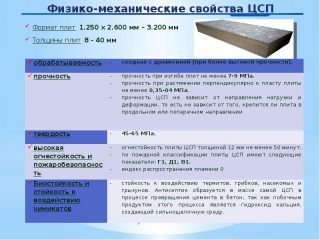

Of technical characteristics important are:

- specific weight - 1100-1450 kg / m³;

- moisture absorption - 2% in 24 hours;

- thickness - 10, 12, 16, 24 or 36 mm.

Application

According to the manufacturing technology, 3 types of DSP are distinguished: fibrolite, arbolite and xylene.

Fibrolite It is distinguished by the use of long wood fibers up to 50 cm. Thanks to this filler, the boards acquire additional strength - the fibers reinforce the material. Fibrolite perfectly absorbs sound and has low thermal conductivity, therefore it is used as additional sound and heat insulation.

Arbolit - sawdust and wood chips, cutting reeds and rice straw are used as fillers. The material is used only in structures without loads.

Xylolite differs in that the binder is Sorel cement, due to which the material is resistant to moisture and can be used in appropriate conditions.

- material with a density higher than 1000 kg / m³ is suitable for the construction of non-load-bearing partitions;

- insulation of external walls with the installation of sheets both inside and outside the building;

- thermal insulation of floors, roofed, attics;

- sound insulation between rooms;

- leveling uneven walls, floors, ceilings before finishing;

- production of permanent heat-insulating formwork when arranging foundations and basement floors;

- fencing with the function of warming beds and flower beds in personal plots.

In all cases, it will be necessary to adjust the DSP to the required dimensions by cutting with further processing.

Features of processing at home

Large mass does not allow working without an assistant. It is advisable to unload in a mechanized way or involve 2-3 assistants.

Fragility DSP leads to the destruction of the slab in case of accidental falls. Additional work and consumables will be required to finish the broken sheet.

High density makes sheets strong, but tools for cutting wood products are not suitable for cutting.

Insufficient flexural strength does not allow the use of DSP in structures with a transverse load, for example, making inclined walls without support.

Plates are not tolerated in a horizontal position, they can break under their own weight. Store products on a flat base.

Dustiness when sawing, it assumes, if possible, work in an open space using personal protective equipment - respirators and goggles.

High coefficient of thermal expansion forces to leave gaps at the joints and abutments of the DSP to the walls. Sealing of joints is not done with cement and hard putties.

How to cut DSP

Shopping centers and warehouses building materials are sometimes provided sawing service... However, do it is inconvenient and impractical, since on site you will have to adjust the sheets to the exact dimensions.

You can cut DSP at home as follows instruments:

- electric jigsaw;

- angle grinder;

- hand circular saw.

Electric jigsaw

The tool is suitable for cutting DSP with a thickness 10 or 12 mm... For work, acquire bimetallic filesdesigned for cutting DSP or asbestos-cement slate. Apply and samples diamond-coated for cutting ceramic tiles.

Regular file for wood or metal is capable of sawing no more than 20-30 cm, after which the teeth of the tool are ground.

When cutting, the board will be less dusty if wet the surface before starting work.

To make the edges even, choose the mode of operation of the jigsaw at maximum speed with rolling off.

Bulgarian

When cutting is highlighted a lot of dust, nessesary to use means of protection... In addition to glasses and a respirator, it is imperative to wear thick protective gloves - chips fly out from under the tool at high speed and can injure the hands.

Disc choose for cutting stone or concrete with diamond dust. The specified rotational speed must be within the specifications of the power tool.

In case of a large amount of work choose a grinder with a power of 2000 W or more - this will allow you to work during a full shift. Difficulties in cutting lie in the plasticity of the material, the disc is locked, the engine overheats from increased load.

Work algorithm:

- A base is prepared from several wooden blocks laid on a flat surface. The thickness of the backing must ensure that the disc does not come into contact with the floor.

- Lay the DSP sheet on the prepared base.

- Marking is carried out with a marker, construction pencil or narrow crayon.

- Spray water along the cut line or moisten the surface with a brush, sponge, or any other suitable method.

- DSPs are cut from the edge to the middle.

- If necessary, move to the other side of the sheet and finish the cut.

If there is a large distance between the supports, they do not walk on the plate, the processing is carried out from the accessible side.

Circular Saw

Cut slabs with a circular saw convenient for reasons:

- there is a support platform, which allows you to firmly fix the tool on the surface, which eliminates chips;

- most models have a branch pipe for connecting a vacuum cleaner;

- protective cover prevents injury;

- the guide allows you to get an accurate straight cut;

- the tool is distinguished by its performance.

The power of the saw is selected based on the upcoming volume of work.

Get a saw disc for working with stone or concrete... Preference is given to abrasive tools with carbide tipped teeth.

The algorithm for working with a circular saw is similar to how they work with a grinder.

Hole cutting

Sometimes you have to make in DSP through holes, for example, for connecting wiring accessories or making niches.

Use the same tool as for sawing, but for a quality edge you will need drill with a drill for concrete.

Operating procedure when making a rectangular hole:

- Mark out the sheet.

- Through holes are drilled at the edges of the rectangle of sufficient diameter for the jigsaw file to pass.

- One by one, the side edges are cut along the markings.

- Remove excess material.

- The corners are being finalized.

Round holes to install the rosettes, they are drilled with bimetallic crowns or concrete crowns. Select a tool with a suitable diameter. During operation, the kick function on the drill is disabled.