Walls and ceilings are sheathed with fibreboards, they are used as a base for flooring. It becomes necessary to cut the fiberboard at home in order to completely cover the surface. The difficulty in sawing is that the sheets are large. They use certain tools and technologies to separate the panels exactly along the line, to get even edges.

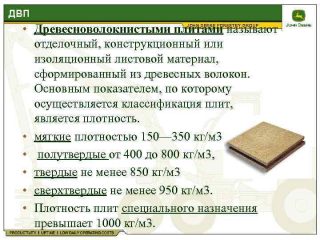

Description and material properties

Dimensions of finished products:

- sheet thickness from 2.5 to 250 mm;

- length - 1.22–3.66 m;

- width - 1.2–2.14 m.

Some types are covered with a laminated film from the front side, a thin layer of PVC is glued.

The scope of use of the material is limited, since the plates are afraid of direct ingress of water, especially from the back side and at the ends.

- super hard;

- semi-rigid;

- tough;

- relaxed.

The choice of tool depends on the rigidity.

The material belongs to the group environmentally friendly building materials.

When used as a floor covering, it retains its geometry, does not change its dimensions.

Types of sawing fiberboard

Sheets can be cut across, lengthwise, diagonally. The cuts can be divided into several types:

- In a straight line. This is how parts with right angles are cut out.

- Curvilinear. Required for cutting circles and elements of complex arcuate shapes.

- Mixed. Some details have right angles and curved shapes.

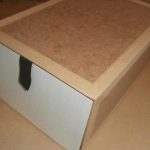

Fiberboard is used for various jobs, but whole panels are rarely installed. Sometimes the sheets are cut into separate parts for ease of installation, for example, on the ceiling. Furniture production requires a lot of cuts.

When do you need cutting

Along the curved lines, the panels are cut to make:

- volumetric advertising letters and other decorative elements on the stage, during a photo session;

- souvenirs;

- original details of designer furniture;

- interior accessories for decoration and repair;

- complex elements of construction formwork;

- curved sections of ventilation ducts;

- door leaves of an unusual shape;

- arched structures.

Artists use fiberboard instead of canvas to create paintings. In this case, a large number of cuts are needed to divide the whole panel into the desired pieces.

Cutting tools and rules

Sometimes it is required to carry out a large amount of sawing work, for example, when repairing a large object. Then they purchase an electric tool to speed up the cutting process, to make the work comfortable.In another case, you need to cut off several or one workpiece, in this case, the material is separated manually. The power tool can be rented.

Use tools:

- electric jigsaw;

- portable circular saw;

- construction knife;

- hacksaw;

- angle grinder (grinder).

In the factory, they use complex equipment in the form of vertical and horizontal cutting machines. The cuts are accurate, since modern lines are equipped with computer programs for marking and electronic control systems.

Jigsaw

Basic rules of work:

- when using an electric jigsaw, the required part is located on the right side of the tool;

- making a cut, a sheet of material is lightly pressed at the point of penetration to the table in order to obtain edges without delamination;

- during operation, both planes of the jigsaw on the sides of the saw should be pressed against the fiberboard plate.

There should be no protruding parts of the table under the sheet of material along the cut, otherwise the jigsaw will cut them along the way or the file will break.

A circular saw

Procedure:

- the panel is laid out on a flat surface;

- the saw blade is placed along the line, resting on the sheet;

- turn on the button, smoothly lead along the line;

- reaching the end, turn off the key, then remove the disk from the panel body.

Suitable for working with fibreboard circle from the grinder, which is inserted instead of the disc into the instrument.

Knife

Work process:

- the sheet is placed on the working surface of the table;

- outline the line along which the cutting will take place;

- an iron ruler or a flat strip of metal is applied along the line;

- the knife is led along the line, resting the side of the blade on the guide rail;

- the cuts are made several times in one section of the line.

For work, you can use the floor surface, since the knife will not go through the sheet through and through.

Hand saw

Sawing procedure:

- with a knife mark a line on the sheet, along which they will cut, slightly cutting through the top layer of the panel;

- an adhesive-backed paper tape is fixed along the line to protect the edge of the material from cracking during cutting;

- with a saw blade, saw the beginning of the sheet strictly along the line;

- the tool is tilted towards you so that the blade cuts the sheet at an acute angle;

- pressing on the saw, they move up and down, pass to the end of the sheet.

If there is an assistant, he can support the panel canvas to reduce vibration.The edges of the workpiece are cleaned with a small file or emery No. 120 - 160 is used. During work, the desired part can be located to the right or left of the master, as it is convenient for him.

The grinder is not recommended to cut wood or artificial boards based on wood waste. An exception is made for low-power devices.... Due to the high speed, the disc can wedge in the fibrous structure and be pulled out of the hands. To work on the grinder, they put on a protective casing, use glasses and a respirator.

How to cut fiberboard at home

Make up cutting scheme panels to use up material economically. For work prepare a horizontal surfaceapply a table or workbench. The base must be stable so that it does not stagger or fall from the vibration of the tool.

The material should be in close contact with the plane. If the sheet is long and there is no assistant, you can use two tables so that the cutting line is located between them. Ensure that the received when cutting the parts had a stopdo not pinch the tool blade.

Figuratively, you can cut out the entire part at once, or perform the work in fragments.