When installing gypsum fiber panels, the area of the walls, ceiling, floor is filled with whole products, but in difficult places, parts are installed according to the size of the site. Cutting gypsum fiber boards is more difficult than cutting drywall boards, since the material has increased strength. Cut edges that fall on the outer corners are protected with a corner profile or processed with a special plane.

Scope and features of cutting

Plating options for GVL and GVLV:

- premises in residential buildings where there is steam, moisture, but there is no direct hit of water jets;

- walls and partitions in utility buildings that are not heated;

- finishing of sports halls, grounds where a rigid base of the floor and walls is required;

- cladding of industrial premises with an increased risk of ignition;

- cladding of attic and attic floors;

- device of window and door slopes.

Slab sizes:

- 1.5 x 1.0 m, thickness 10 mm;

- 1.2 x 1.2 m, thickness 10 mm;

- 2.5 x 1.2 m, thickness 10 mm;

- 2.5 x 1.2 m, thickness 12.5 mm.

Manufacturers produce small-sized panels to reduce the number of cut parts, but you still have to cut the gypsum board to cover the surface.

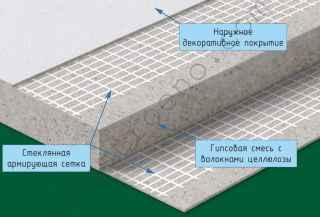

Material description

Release types of gypsum fiber boards:

- GVL - common material, not resistant to water;

- GVLV - sheets have moisture-proof qualities.

The moisture-resistant version is installed in production workshops where processes with the release of wet vapors take place, while sanitization is allowed. The introduction of hydrophobic additives into the gypsum mass allows the use in bathrooms, residential and public kitchens.

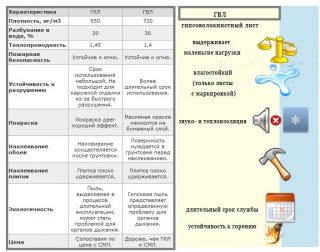

The finishing material was created later than drywall, so it is devoid of its shortcomings, but it has acquired many advantages. The first advantage over GCR is increased strength and more long service life as a leveling layer.

- Drywall has many types of beveled edges, which are intended for sealing seams, but do not release straight sides. GVL has varieties: PC - straight edges and FC - a kind of folded edge.

- Plasterboard sheets are placed on the frame without clearances between them, and the GVL panels are placed with an interval of 5 - 7 mm (for the convenience of sealing the seam).

- Racks under the gypsum board, they are mounted with an interval of 600 mm, and the vertical elements of the lathing under the gypsum fiber boards - with an interval of 603 mm, so that it is possible to form a gap between the sheets.

- When installing a two-layer coating of partitions, gypsum plasterboards of the first and second tier fasten in profile with self-tapping screws. GVL is allowed to fix self-tapping screws not only in the racks, but also in the panel of the previous layer.

- Do not put drywall on the floors as a rough layer, since it does not have enough strength, and GVL can withstand operational loads in the room.

When installing moisture-resistant fiber boards between the ceiling and the wall, leave mounting gap 5 mm. They are joined to the floor with a gap of 10 - 12 mm. The screws are turned at an angle of 90 °, they go to a depth of 1 cm in the profile.

Set material face outward, it can be identified on a flat surface without rough protrusions. On the wrong side, a marking of letters and numbers is applied. On the face there is a marking for drilling with self-tapping screws in the form of dots.

Tools required for work with GVL

Panels high compressive strength, but low bending strength, therefore, the material is classified as fragile. You need to know exactly the rules for cutting, and how to cut the gypsum fiber sheet.

Mark out the details with a tape measure and a pencil.

For cutting use tool options:

- construction knife or cutter;

- special hacksaw;

- Bulgarian;

- a circular saw;

- jigsaw.

Knife you will need a sharp one, so you will often have to change the removable blades with a width of 12 mm, since they will blunt against the plaster base. The tool is used if you do not need a perfectly flat edge or the end will be located under the corner. The GVL hacksaw has the correct slope of the teeth and the original sharpening, during operation, almost no dust is emitted.

On the grinder set the disc over the stone. The tool generates a lot of dust when cutting, therefore protective respirators must be worn. Circular Saw will also handle cutting quickly, but with these power tools it is better to work outdoors or in a well-ventilated area.

Suitable at home electric jigsaw with vacuum function, which can cut GVL without dust and quickly. A file for wood with wide 4 mm teeth is placed in it. The jigsaw is good because you can make not only rectangular cuts, but also cut out curly lines, cut holes in the panels.

Cut ends clean plane, on the surface of which there is a grater with metal sharp protrusions. In case of failure, such graters are replaced with spare elements.

Rules for cutting slabs without chips

Before work, choose the surface where the cutting will take place. This should be a flat area. A wooden strip 20-25 mm thick is placed under the marked line along the entire length of the cut. The blade of the disc is led evenly, without moving from the line, it is not recommended to rush when working.

Sawing gypsum fiber super sheet from Knauf

The option of cutting with a hand tool, for example, a knife, a cutter, is used most often. The power tool will generate dust.With a small amount of work, simple devices can be dispensed with.

Sequence of work:

- lay the sheet on a flat plane, you can cut the top sheet on the package without removing it;

- markings are applied to the panels, a rule is applied along the line, it is pressed well;

- cut through the line with effort several times, trying to evenly immerse the blade;

- a bar is placed under the cutting line;

- the edge of the slab is raised, broken down along the line, dividing it into parts.

If you need to do fold on a straight edge, use a cutter knife or chisel. For large volumes, they work with a router with a 4 mm groove cutter. To fit pieces of gypsum fiber board in place, use roughing plane.