There are many types of finishing panels for interior and exterior work. The cladding is easy enough to cut, saw and fasten, as it is designed for quick and easy installation. However, each material has its own characteristics.

Features of PVC panels

Make panels by extrusion: in a special injection mold - a die, raw materials are poured under high pressure - PVC melt... The initial mixture also includes other additives, for example, ground natural chalk, coloring pigments, plasticizers.

Additives provide the material with its properties:

- high water resistance - not afraid of steam, water, snow;

- chemical inertness - does not react with household chemically aggressive substances;

- electrical insulating properties - plastic does not accumulate electricity;

- elasticity and some elasticity - with low mechanical strength, this quality allows it to withstand the load and not deform;

- durability - up to 50 years;

- decorativeness - panels reproduce any color and texture of any natural material.

It is not only the shade that gives the product an attractive look. More interesting is thermal option... In this case, the pattern and structure of the panel is provided by a thermal film. On a special machine, the film is rolled with a hot roller and pressed. The film adheres firmly. Such lamellas do not need to be varnished.

The texture is created and offset printing... But at the same time, the panel must be varnished.

Things to Consider Before Cutting

Before cutting PVC panels, take into account:

- Low resistance to heat - plastic is not designed for operation above + 50– + 60 ° С. At a temperature slightly above + 100 ° C, it begins to melt and deform. Therefore, tools that heat the material must not be used for cutting.

- Working conditions - as the temperature drops to 0 ° C and below, the plastic becomes brittle. Cutting plastic panels during winter work must be extremely careful. It is advisable to cut in a room where the temperature is higher. Before installation, the panels are taken out into the shed or under the shed so that they adapt to the cold. In this case, the increased fragility does not matter anymore.

- Dimensions (edit) - the standard length of the facing sheet is 3 m. It is inconvenient to work with such large panels. However, in addition to the usual cut along or across, curly cutting of PVC will be required. To do this, you need to choose a more maneuverable tool.

The material has uniform structure, so you can cut it in any direction. It is important to find the right tool.

Tools for cutting panels without defects

To adjust the length or width of a pair of lamellas, a simple hacksaw is sufficient. But if there are many sheets, it is worth choosing a more powerful tool.

Are used 2 types of cutters.

- Mechanical - cutting is carried out with physical effort.The speed depends entirely on the capabilities of the employee. This method is preferable for curly cutting, as it requires patience and accuracy. The mechanical ones include hacksaws, knives, cutters, hand jigsaws.

- Power tool - the worker guides the cutting blade, but does not exert his own efforts. In this way, many more panels can be cut. Representatives of the category: circular electric saw, grinder, jigsaw.

Hand tools are cheaper to use. Electric requires a connection to the network, but it is much more efficient.

Knife

For cutting, they take a clerical, construction and even kitchen knife. The best option is constructionas it is better balanced for this kind of work. When using stationery, for example, you will have to cut under an angle, which is not very convenient.

For cutting along 3-4 sheets are best painting knife... He has a very thin and sharp blade, the cutting line is also thin and neat. However, it will not work to cut across the lamellae with a molar knife.

Hacksaw

The hand saw is ideal for the job. The cutting line is thin, without chips, since the small teeth do not grab the filament. You can cut up and down, diagonally, since the speed here is determined only by the applied forces, the risk of thermal melting of the panels is extremely small.

Jigsaw

Allows for longitudinal and crosswise cuts several sheets at once... The tool has the advantages of a hand tool, but when using it, the employee is much less tired. However, due to the speed of movement of the teeth, it is extremely difficult to do curly cutting with its help.

Need to work at minimum powerso that the plastic does not deform from heating. If the tool is hot, you need to stop and wait until it cools down.

Bulgarian

For cutting panels grinder does not fit well: The rotational speed of the disc is very high, the material heats up during operation. Therefore, they take low-power models and the thinnest disc - 0.8 or 1 mm. A definite plus: thin and precise cut regardless of plastic temperature and weather conditions. The grinder can be used to cut the cladding in the cold. Minus: emits a lot of dust.

Circular

The circular saw is also designed for handling large volumes of material... The tool provides a perfectly smooth cut of several sheets at once. Cutting is allowed in any direction. For the file, you need to take a special disc for plastic or a model for soft wood, plastic and aluminum.

Prevention of errors, safety engineering

When cutting plastic panels at home, it is important to follow the rules for handling the material. Otherwise, an even cut cannot be achieved.

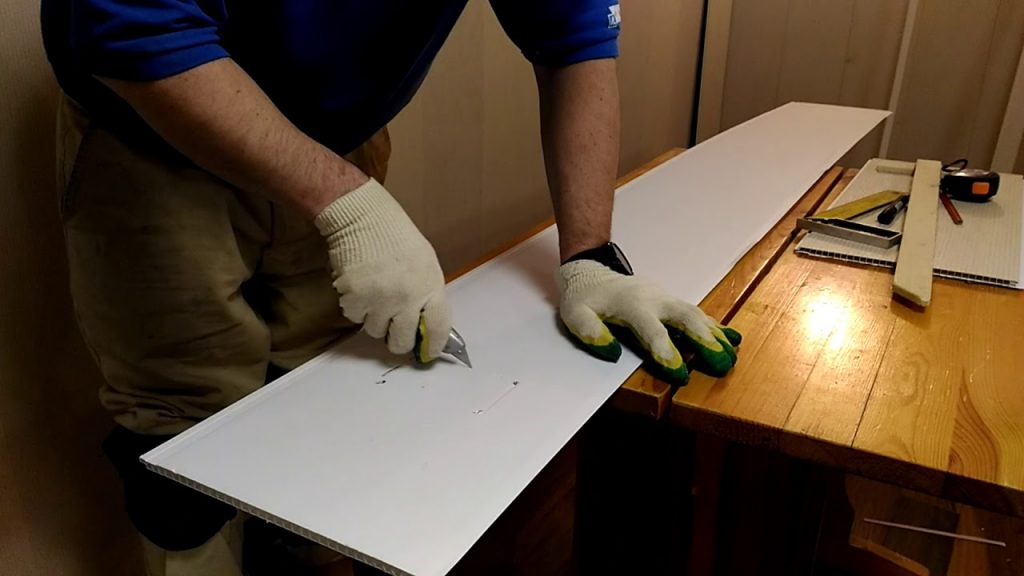

- Panels are placed face down... As a rule, the outer side of the panels reproduces some kind of structure, has a relief. When cutting directly, the texture is wrinkled, cracks and dents appear. From the inside, such defects are also possible, but they remain invisible and do not affect the custom characteristics of the material.

- Before work, mark on the panel with a pencil or felt-tip pen cutting line... This greatly simplifies processing, especially if you need to make a curly cut. Marks are easily erased from the smooth surface of the material.

- It is forbidden to cut plastic in the cold... Panels, immediately after transportation or transfer from the cold, are left in a room with a temperature of up to + 10 ° C for a day and only after that they start to work. When cooled, the material becomes brittle and difficult to cut.

- To shorten the preparation time, they often cut several sheets at once... You can do this, but you need to follow some recommendations. Sheets need to be laid on a two-point supportso that they do not bend during operation and do not sag. The panels are laid tightly and precisely. It is advisable to abut the opposite edge of the pack against the wall in order to avoid displacement of the sheets relative to each other.

- Quite a lot of dust is emitted during cutting, so work is better done in a respirator or in a gauze bandage... In addition, the appearance of small chips and fragments is possible. Their edges are not too sharp, but they can cause injury. When cutting, you need to wear glasses, protect your hands with gloves.

The appearance of microcracks on the seamy side is considered by some manufacturers to be the norm.