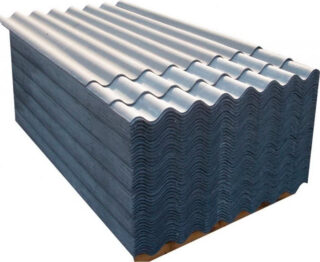

Slate is fragile enough if handled incorrectly. During the sawing process, it can crack in the wrong direction, and the damaged sheet can no longer be used as a cover. You need to cut corrugated slate with an electric tool to speed up the process, but sometimes mechanical cutters and other devices are used to reduce the amount of dust.

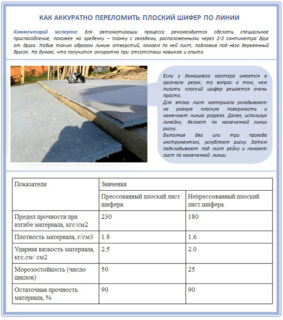

Features and properties of slate

Depending on the number of waves on the surface, there are 5-, 6-, 7- and 8-wave products. They differ in profile thickness, ridge parameters, length, width, weight, color, physical and chemical characteristics.

Flat and corrugated sheets are produced according to the same technology, the composition includes Portland cement, asbestos fibers, water. The properties depend on the volume of cement and the amount of chrysolite asbestos.

Material characteristics:

- slate is produced with a thickness of 5.2 to 8 mm, a width of 980 - 1130 mm, a length of 2000 - 2800 mm;

- pigments are added to the raw material, therefore products of different colors are obtained, coloring on the surface additionally increases moisture resistance, improves strength properties;

- the slate layer can withstand a weight of up to 200 kg per square of surface, so people can walk on the roof during installation and repair;

- density at the level of 1.6 - 1.7 g / cm³, with an increase in the indicator, the strength and weight of the products increases;

- frost resistance at the level of 25 cycles of mark 54/200 (wave height 54 mm, step 200 mm) and 40/150 (wave height 40 mm, step 150 mm) 6 mm thick;

- material with a thickness of 7.5 mm of the specified parameters can withstand up to 50 cycles of freezing and thawing without destruction and deformation.

The slate is durable, its use is designed for 25 - 40 years of operation. The material does not conduct heat, insulates the room from noise.

Disadvantages in the large mass of panels, therefore, it is necessary to strengthen the rafter structure. But under the slate, you can use a sparse sheathing system, which saves wood. Moss can grow on the surface of the coating, which must be periodically cleaned.

The need to cut roofing slate

The dimensions of the roof slopes are different, therefore, when installing piece roofing elements, they must be cut to the desired size. Slate can be cut using different methods, the choice of tools depends on the physical properties of a particular sheet model.

Slate properties regarding cutting:

- asbestos or mineral fibers in the composition are easily cut even with a knife, they are pliable;

- hardened binder cement gives the material strength comparable to that of dense oak and teak wood.

Slate slabs are cut along the grain if they do not fit along the width of the eaves. Slate can also be cut along longitudinal lines if the distance from the ridge to the overhang is not a multiple of the length of the sheet.

Basic rules for cutting and dust-free work

Regardless of the choice of method for cutting panels, the recommendations for the use of tools must be followed. This is especially true for electric types, since a lot of dust is emitted at the same time. Slate based on asbestos fibers is harmful to health, because.the smallest particles have a bad effect on the state of the respiratory system.

In most cases, such fibers are held together by cement grains, which securely hold the threads and prevent harmful emissions from spreading. There is little harmful effect from the roof covering, since the material is in a restrained state. To enhance the harmlessness, it is recommended to paint the slate profile. But if the integrity of the web is violated (cutting), the particles of the fibers are released into the air and have a harmful effect on health when inhaled.

Conditions that need to be created to cut the slate:

- work is performed in the open air, since dusting in a closed hangar, shed is not permissible;

- it is advisable to arrange the workplace so that the wind carries the dust stream away from the master and adjacent premises;

- wet material emits much less dust, so the cutting site must be moistened with water, using rags, brushes, watering cans for this.

The raw profile is less dusty during processing, it is much easier to cut slate moistened with water. Wet sheets get additional elasticity and soften.

The panels are positioned so that the two parts that are obtained after cutting have reliable support. Otherwise, one of the sharp-edged halves may injure the operator when separating.

Electric tools

Use a cut-off saw with a stone cutting disc. Preparation includes marking the line on a slate sheet, wetting the cut. When working, you must not allow displacement from the intended line, drawing exactly along it.

It will not work to cut off a part at a time, therefore, after wetting, they additionally outline a line, simultaneously deepening it with a core. This will prevent the disc wheel from straying off the mark. In the case of using a circular saw, several approaches need to be taken.

An electric drill is used with a drill, which has a victorious tip.

Work order:

- the sheet is laid flat on a leveled surface, on it, across the waves or along them, a line of separation is marked;

- holes are drilled on the marked line, as close as possible to one another, drilled to the end of the sheet, while trying not to move away from the line;

- take a hammer and tap on the row of holes every 6 to 10 centimeters;

- one half of the panel is lifted, carefully separating it from the other side of the sheet.

Some roofers additionally cut the line through the holes with a sharp ax blade. This procedure is not necessary, since the plate will split in the direction of the drilled holes. They do not take a drill with an impact effect (perforator) for work - such sharp efforts will lead to the appearance of an oblique crack not along the intended line.

Cutting sheets of asbestos cement with a grinder or jigsaw

In the first case, a continuous water jet is provided at the point where the circle touches the slate surface in order to cool the working edge of the disk and prevent dust. For convenience, the work is performed with an assistant who uses a hose or a plastic bottle with holes in the lid. For single work, the hose is fixed in a comfortable position.

Operating procedure:

- The sheet is laid on the floor, if you need to cut off a narrow edge, then a wooden block or board is placed under it.

- The first cut is made along the marked line on the wave ledge from the beginning to the end of the panel.

- The slab is turned over, the place of the cut is obtained in the concave region of the sheet.

- Cut along the line, if everything is correct, then the profile will be divided into two parts;

- Dust on the side surface of the disc is removed with a wet cloth immediately, if it hardens, the disc will have to be thrown away.

In the case of using a diamond disc on a grinder, the sheet can be cut in two directions and it is not necessary to turn the panel over. In winter, it is recommended to lay asbestos-cement slabs directly on the snow - this is how the emitted dust is mostly absorbed into it.The edges of the material are ground with a diamond wheel in the cutting pest to increase resistance to negative factors. The disc is used to trim the corners of the profile if the sheet does not move halfway during installation.

You can cut flat slate and corrugated sheets with an electric jigsaw. To do this, insert a file with fine teeth into the tool, set the operating mode with a reduced gear. When cutting, do not press on the slate with the jigsaw runners, so as not to crumble the material. A jigsaw is used in the case of a small amount of work.

Mechanical tools

Hand tools are used for small cutting volumes. If the work takes place in closed garages and other rooms, you can cut the wave slate with improvised means.

They take a hacksaw to sweat metal, which has small teeth, and there is the possibility of replacing the blade. Spare parts will quickly become blunt on hard cement, so they are stocked up in advance. A hand saw is used if you have the skill of cutting without pressing and skewing, so that cracks do not go on the slate. Hacksaw blades are taken from high-alloy metals to withstand the physical stress from processing hard material.

Parameters matter:

- Saw teeth size. For canvases for metal, the size does not exceed a millimeter, such elements are more durable.

- Sharpening angle. It is important that the lower flat parts of the teeth are sharpened, since steel is cut with these surfaces.

A sharp knife or hand cutter is also used. Before using them, the markings are deepened exactly along the intended line, for this they take a solid core. The cutter is then used. It is important not to deflect your hand, to make the incision exactly along the mark.

Break off a piece of the sheet after the knife goes deep into the thickness of the material by 2/3 of the sheet in thickness. For the procedure, a wooden even block is placed under the panel at the incision site. Press on the edges of the sheet with your hands, while it should be divided along the line. Choose a sharpened knife or cutter without burrs on the edge of the working blade.

Operating procedure:

- A fault line is marked on the sheet.

- Holes are punched along it as often as possible and closer to each other, from beginning to end along the entire length of the cut.

- If the line runs along the wave, the panel is flipped so that the line is at the bottom (trough).

- A wooden longitudinal lumber or any pipe is substituted under the seam, pressure is applied to both edges of the sheet (preferably with an assistant), the two parts are separated along the cutting line.

Despite the outdated technology, this method has an advantage over using an electric tool. When breaking the sheet and punching with nails, little asbestos dust is emitted, which is important for the environmental friendliness of the workplace.

The evenness of the cut depends on the number of holes and the accuracy of the master. You can tap the row of holes with a hammer to help separate the two pieces of the sheet.

Features of cutting flat sheets

Work schedule:

- By analogy with a corrugated profile, flat panels are laid on a flat surface, ground or floor.

- A board is placed under the edge to be cut off.

- The place of the cut is spilled with water.

- Cut in several passes, each time cutting by ¼ of the sheet thickness.

You can take a diamond disc. In any case, you need to work carefully, without unnecessary pressure and distortion of the blade to the side of the line.

Safety precautions and recommendations

When cutting, be sure to wear respiratory protection in order to protect yourself from inhaling harmful asbestos particles. The effectiveness of gauze and paper masks is low, so it is better to use respirators in which filter elements can be changed.

The fragile material gives rise to many small debris that fly to the sides and upward under pressure, especially when working with a power tool. Wear safety glasses to protect your eyes. Gloves and special clothing are used to protect hands and body.