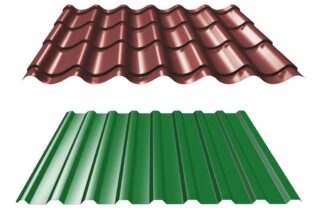

The use of stamped steel sheets as roofing is popular in both private and commercial construction. Profiled sheet, metal tiles are available in various formats and textures, which affects their price, installation methods and partly on the scope. To choose between corrugated board and metal tiles, you should familiarize yourself with the features, advantages and disadvantages of each material.

What is metal and roofing sheeting

Corrugated board represents metal sheets, on which the longitudinal ridges of the waveform, rectangle and trapezoid are made by stamping. The metal is coated with zinc and painted, followed by applying a protective coating. The standard size for household use is 110x200 cm with base thickness 0.45-1.2 mm... Distinguish between wall, roofing and universal type of profiled sheet.

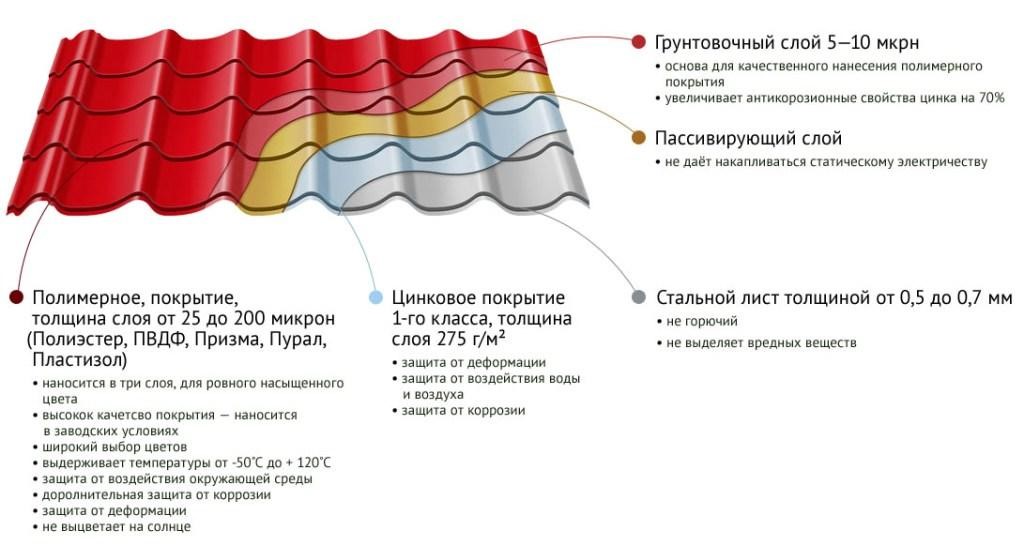

Metal tile also stamped from cold rolled steel, but with another embossing option... It imitates natural clay tiles with already transverse ridges. Since it is a purely roof cladding, its parameters are adapted to the application. Panels are used to equip the roof 40x100 cm, and the thickness of the metal varies within 0.4-0.6 mm... The variety of protective coatings is greater, and their quality is higher.

Roof tiles and profiled sheet, having almost the same composition and structure, differ quite noticeably in weight. The first type of coating is lighter and thinner, the second is heavier, thicker and stronger.

Criterias of choice

Materials should be considered from the point of view of manufacturability... The difference in the arrangement of both materials is quite significant, which affects their cost and resource.

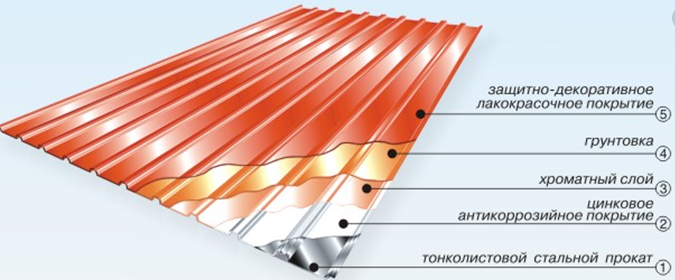

The profiled sheet is processed with an alloy of zinc and silicon. Such a coating is durable, strong, but not elastic. From above, the workpiece is covered with a passivating and primer layer, as well as an additional polymer coating.

Designed for long service life and good visual effect shingles have more layers of protection. An aluminum film is applied over the zinc, which is a reliable protection against corrosion. Then comes the primer and a layer of polymer, fixed with varnish. Glossy and matte polyester, pural, plastisol and PVDF are used as protection. The thickness of the spraying is 25-300 microns, which affects the resistance of materials to moisture and ultraviolet light.

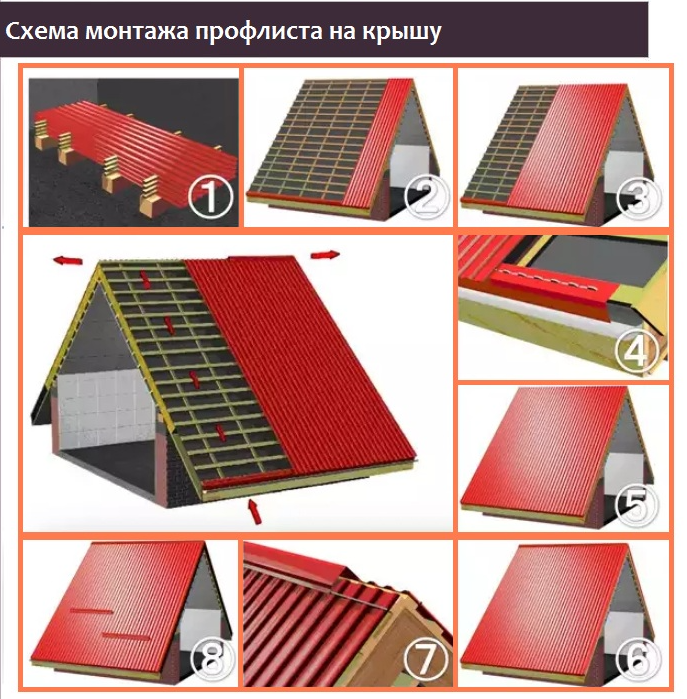

Choosing between a profiled sheet and a metal tile, you should focus on their sound insulation properties... They are almost the same, but there is still a slight difference. On the tiles inflicted thicker layer polymer coating. There is not much of it, but enough to better absorb the sounds of the street and muffle the ringing from falling drops, turning it into a knock, not a bounce. This property allows you to save on the installation of heat-insulating materials, without which the flooring from the profiled sheet turns into a tambourine during the rain. Slate and siding are much more effective in this regard, but the first material does not last long, and the second is not airtight. In all cases, the solution lies in the installation of a roofing cake consisting of insulation, waterproofing and a vapor barrier. Here and moisture protection, and silence.

Not the least important for a private developer is the presentability of the building.The profile looks simple and inconspicuous even with the most exotic coloring. The shingles look much more impressive.

Terms of operation of metal tiles and corrugated board

The service life of the materials is important in terms of finances and prospects for the comfort of living in a building.

For the duration of operation influenced by the following factors:

- Metal thickness. The larger it is, the more efficiently the flooring resists wind, snow loads and mechanical stress.

- Primary Coating Type. Zinc lasts less, its alloys last a little longer, and aluminum has the longest life.

- The composition of the protective coating. Polyester gives a guarantee for 10-15 years, polyurethane for 30-40 years, pural for 50, and plastisol for 60-70 years.

Since higher quality polymers are used for metal tiles, it will last longer if it retains its original shape.

Application area

Stamped roof tiles used by exclusively as roofing... The sheets are thin, beautiful and have a limited margin of safety. They are used to decorate residential buildings with gable and hip roofs, as well as other courtyard buildings to create a single and harmonious landscape design. The coating looks good on the garage, sauna, gazebo, veranda. Visors are made of it over the gates and entrance doors.

Decking has a wider scope, which is not limited only to roofs. Sheets are used for wall cladding, partitions, temporary and permanent fences. Wall panels are even used to create auxiliary buildings, since the slabs have high mechanical stability.

If you choose a corrugated board, you can finish the entire area with it, while tiles can only be used for roofing systems.

Which material is easier to install

Building materials can significantly differ in the complexity of installation... Understanding the installation technology helps to assess your capabilities and make the most feasible decision. You need to proceed from the size and weight of the panels.

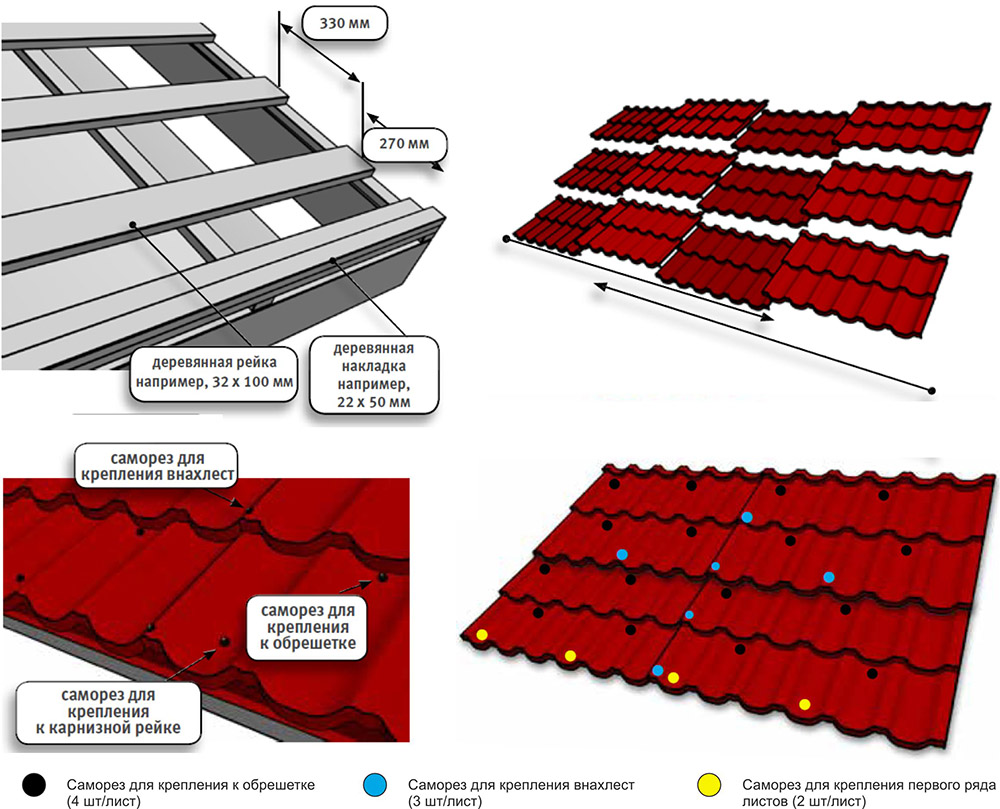

Laying tiles requires careful measurements and calculations. It is required to make frequent, and sometimes continuous crate. In the course of work, it is necessary to constantly adjust the panels horizontally and vertically, to monitor the maintenance of the size and pattern. The details are small, it takes longer and more difficult to fix them.

Profiled sheets are larger, heavier, but not so much as to make significant efforts to handle them. Plates are much easier to align and fix each other due to the longitudinal structure and the alignment of the longitudinal ridges. The presence of profiles and thickness ensures the rigidity of the material and a lesser likelihood of deformation during installation.