Roof tiles have been used since ancient times. It has not lost its popularity to this day. Different types of tiles are used, each of them increases the aesthetic appeal of the house, since it creates a feeling of solidity of the building and closeness to nature. The material is made from natural ingredients, synthetic polymers are also added to improve quality.

Description of tiles and components in the composition

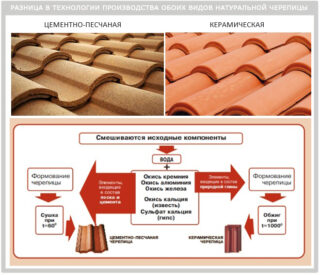

Shingles are made from scorched clay (ceramics), thermoplastic combined composition... Apply the solution based on cement and sand (cement shingles), add lime and treated with high pressure (silicate variety). A common type is products from low-melting kaolin with the addition of chamotte.

All varieties differ in the origin of the components, the properties acquired during the production process. Becomes popular in construction flexible shingles, which is called soft or bituminous.

Shape and patterns

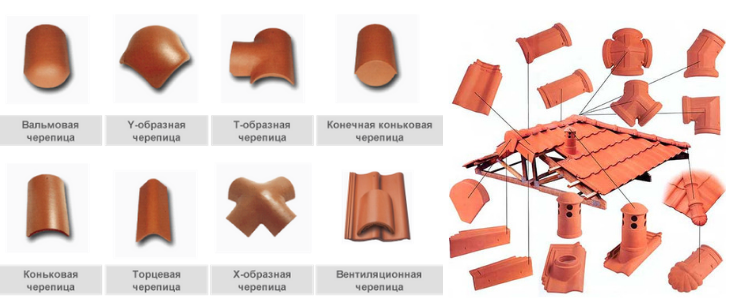

In appearance and shape distinguish between products:

- groove (pressing or stamping);

- flat (ribbon-shaped);

- ridge;

- special elements for installation at junctions, ventilation outlets, there are T-shaped parts, X-shaped.

There are many varieties of tile elements, which are grouped into categories for similar properties and characteristics.

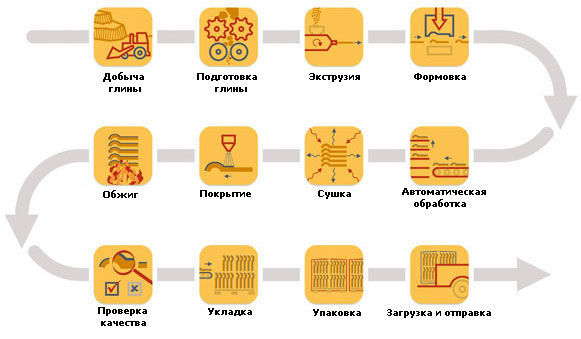

Clay tile production

Production includes cycles:

- Career work. An excavator is used which loads a conveyor that moves the clay to the hangar. Indoors, large particles, heterogeneous inclusions are removed from the mass, and they withstand it for a certain time.

- Mix the components in a special unit, varieties of clay, quartz sand, tile flour are poured. The dry mixture is passed through millstones, then diluted with water. The wet mass is crushed with rollers.

- The mass is passed through the screws for plasticity. A tape comes out from there, it is cut into pieces of a given size. The shape is formed by pressing.

- Before firing the workpiece dried in cells, then fired at rates of +450 - 600 ° С, secondary heat treatment takes place at + 1000 ° С.

Varieties of material

Clay tile for the roof they are not painted, but after firing they are treated with glaze.The variety of color is regulated by different types of clay. This type is done on a high-tech line, which affects the cost. They produce natural tiles (without a covering layer), engobed and glazed.

Coating options:

- Engob is a moist powder clay with the addition of minerals and metal oxides. During firing, the particles give a different color.

- Glaze represented in production by a vitreous mass, which contains metal oxides. The layer is applied to the tiles before firing.

Cement-sand tiles are painted by adding pigments and additives with an increased ability to capture ultraviolet light to the mass.

Soft (flexible) cover

The main ingredients are:

- oxidized or modified bitumen, plastic, rubber;

- fiberglass canvas;

- granulate (mineral dressing).

In the roof structure they put on a solid crate, provide a layer waterproofing... The latter is mounted over the entire plane or provided at the joints of the strips. In the insulated version of the roof, a plate or roll insulator is used.

For joining with chipboard sheets use self-adhesive layer on the bottom of the shingles... In difficult places or with a large slope, galvanized nails are used.

Cement-sand tiles

In the conditions of the plant perform stages on special equipment:

- the components are mixed in mixers;

- then injection molded;

- dried in chambers with a temperature over + 60 ° С for 10 - 12 hours.

To obtain color, the pigment is added to the solution, but the samples are also painted over the surface. The first time they pass the paint on a wet plane immediately after leaving the molding container, the second time the composition is applied after final drying.

Polymer-sand

The raw materials are Components:

- waste plastics;

- sand;

- crushed quartz chips;

- silicate.

The concentration of soft and hard polymers is allowed such that the former are in the composition by 10% more. The sand is subject to moisture requirements, which should not be higher than 5%.

The ingredients are mixed in a melting chamber, the hot mass is weighed, laid out in molds, and pressed. Finished workpieces are naturally cooled on a rack.

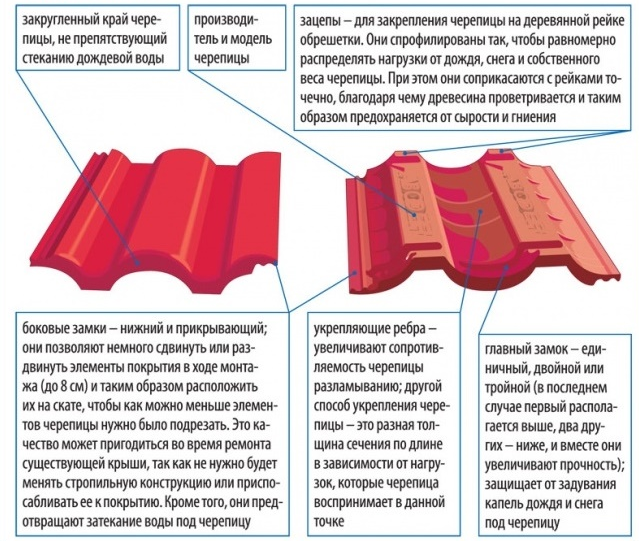

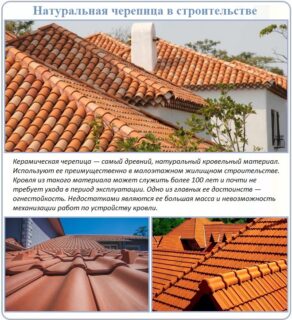

Natural ceramic tiles

Other positive characteristics:

- condensation does not form in the roofing cake, since ceramics let steam through;

- the surface of the tiles does not become thinner under the influence of wind, rain and sun;

- a covering made of natural material does not need to be grounded;

- the surface looks beautiful and rich.

The disadvantage of ceramics is their high weight and high cost of elements. The shingles can crack when heavy objects and branches fall on the roof.

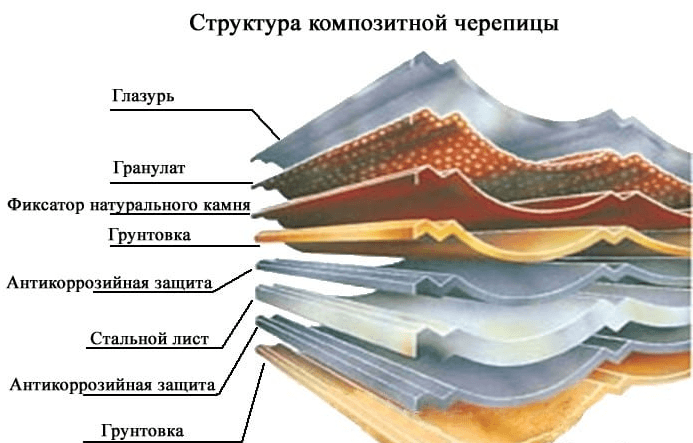

Composite tile roof

Includes:

- rolled steel sheet;

- anodized film on both sides of zinc, or zinc with aluminum;

- granular powder on the front side, made over the polymer-paint layer.

Zinc coating protects the metal from corrosion, additional protection is provided by a polymer coating.The crumb on the surface allows ultraviolet rays to be refracted to preserve the color of the surface for a long time.

What to consider when buying

Buy material from trusted suppliers, in large stores, from brand representatives. The material must have all the documents, be sure quality certificate and compliance with international standards. On the Internet, goods are ordered directly from the manufacturer.

Simultaneously order additional elements, which give a special color to the roof, in comparison with the one where the decoration is made with rectangular metal ridge, without picturesque cornices and overhangs. All parts must have one shade, for this, the RAL color catalog is used.