For fastening the metal coating, a solid base or lattice structure is made. The lathing is arranged along the rafters, while taking into account the step of the metal tile, which depends on the size of the waves on the surface of the material. The correct choice of the frame and adherence to the installation technology determine the quality of the roof. To do this, you need to calculate the gap between the slats, their size and number.

- Metal tile step concept

- Metal tile roof structure

- The role of the lathing

- Types of lathing

- Solid crate

- Sparse base

- Counter grill

- Selection of material for lathing

- Choosing between wood and metal

- Determination of the pitch of the lathing

- Measurements when constructing the lathing

- Sheathing step for Monterrey and other species

- Preparing the roof for installation

- Laying the first purlins

- Possible mistakes and expert advice

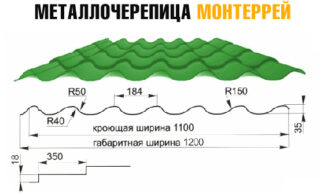

Metal tile step concept

The distance between the elements of the sheathing depends on the wavelength on the sheets of metal, such a characteristic is indicated in the technical documents for the material or in the installation instructions. The stepped structure of the roofing material makes it necessary to attach each undulating module to the support.

Waves can be 300, 350, 400 mm long, and the profiling height becomes the reason for the division into categories:

- economy, while the section height does not exceed 28 mm;

- medium - in the range of 30 - 50 mm;

- elite - in the coverage of 50 - 80 mm.

An increase in the pitch of the board under the metal tile over the classics becomes the cause of the deflection of the coating. The parameters of the metal profile differ not only for different groups, but also for manufacturers. The height indicator affects the cost of the tiles, the step and section of the lathing elements.

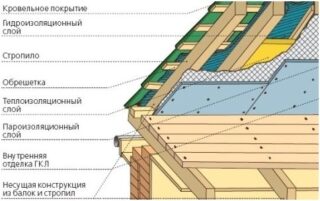

Metal tile roof structure

Depending on the purpose and shape of the roof, the composition of structural elements and material layers changes. The thickness of the components in the roofing carpet is determined by the climate, wind, snow load, and the slope of the rafters.

Two main types of roofing can be made with metal roofing:

- Cold. This is the name for metal roofs, the installation of which does not provide for the installation of insulation, but only waterproofing. An inexpensive coating option can be installed on seasonal buildings, garden houses, unheated buildings.

- Warm. Lay over residential buildings that are used all year round to reduce heat loss. The scheme additionally includes insulation from cold, vapor barrier.

The operation of any type of roof can be extended if the roofing "pie" is correctly assembled and the correct calculation of the amount of lathing for metal tiles is made.

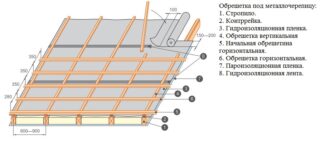

Layer-by-layer scheme of a warm roof:

- the top layer of metal tiles;

- a compensating rail for a metal tile, a tape must be attached between it and the metal to reduce vibration from rain, birds;

- waterproofing film;

- counter-lattice consists of longitudinal slats along the rafters;

- thermal insulation layer;

- rafter legs;

- vapor barrier membrane;

- inner lining of the ceiling.

Each layer does a certain job as part of the roof, so the installation order cannot be violated. Before installation, you need to calculate the total weight of the roof in order to accept the cross-section of the rafters. They should not bend when the enclosing structure is fully loaded, taking into account snow drift or lateral wind pressure.

The role of the lathing

The frame for the metal tile serves as a support and base for fixing the material.Elements are stuffed end-to-end or leave gaps, which are called a step. Wooden bars are fixed with nails, staples, self-tapping screws, metal slats are connected by welding or bolts.

A set of bars laid perpendicular to the rafters performs the following functions:

- creates an opportunity for laying insulation, waterproofing;

- creates a supporting frame for the roofing material;

- levels the installation surface.

When laying out, a counter-lattice is installed as a mineral wool insulation. The cotton wool is saturated with condensation and loses its properties, therefore, the ventilation of the under-roof space is organized with the help of additional slats that need to be nailed along the rafters.

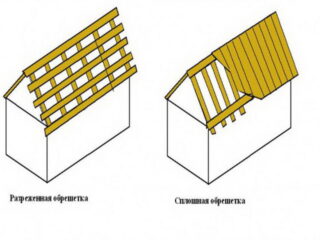

Types of lathing

Solid crate is called when the gap between the boards is made no more than 1 centimeter. For this type, antiseptic sheets of chipboard or OSB panels are used.

The sparse crate is placed with a certain step, which is chosen as a result of calculating the loads, taking into account the distance between the waves.

The combined base means the combination of a sparse frame and areas of a continuous coating for metal tiles. In this case, in the places where the valleys, the bottom of the eaves overhang, and ventilation outlets are designed, a single layer is installed, and in the rest, slats are used with a gap.

Solid crate

This type of frame is used with a slight slope of the slopes (14 - 20 °). In this case, the minimum roof slope, which can be filled with tiles, is taken at 14 °. A one-piece crate must be placed with small gaps so that there is room for a slight shrinkage in case of expansion from moisture.

A solid base is always placed on difficult parts of the roof:

- at the junction with parapets, chimneys;

- on the cornice section;

- in the area of the ridge, grooves;

- when arranging roofing and dormer windows;

- under the places of attachment of snow holders, stairs, bridges.

A solid frame can be in one or two layers. The first is usually fixed in a horizontal direction, parallel to the ridge, and the second is laid down from the roof ridge. Sometimes the elements of the second flooring are placed along the diagonal of the ramp.

Sparse base

For this option, take wooden blocks, use unedged and edged boards. The steel frame is made from a metal corner or a rectangular or square profile pipe is mounted.

Device rules:

- laying direction - from the ridge ridge to the eaves overhang;

- the distance between the battens is performed exactly according to the calculation, taking into account the covering plane, which is covered by the step of the wave of the metal tile;

- they join the slats or boards on the rafters; they do not make connections in the air.

On junctions and in difficult places, boards are placed in 1 - 2 rows. At the ridge, the boards are mounted so that the metal tile of the two slopes does not touch and a small gap is obtained. A sparse base is used in cases of a roof with a steep slope, while paying attention to the prevailing wind force in the region. In this case, the weight from snow is taken into account using a reduction factor, since it will not linger on the slope.

Counter grill

For installation, take even bars and dry lumber without knots. The section of the elements depends on the slope of the roof. For a larger slope, use a reduced size, and increase it on flat ones.

The role of counter battens in the roof structure:

- fixes the insulating layers laid on the rafters;

- contributes to additional noise insulation of the roof due to the air gap;

- ventilates the gap between the waterproofing and insulation, conducts air flows for the natural drying of condensate;

- levels the unevenness of the rafter system.

The width of the counter-lattice bar should not exceed the corresponding size of the rafter legs. The elements are placed on the rafters, so their step is equal to the distance between the inclined supports.The bars are taken no more than 1.5 m long, fixed to the rafters with self-tapping screws every 30 cm in length.

The balance is observed so that the film stuffed along the counter-lattice sags a little for condensation to drain off, but does not touch the insulation located under the lattice.

Selection of material for lathing

Use wood, the grade of which is not lower than the second. The width is taken no more than 140 mm, since more voluminous elements are twisted over time, distorting the plane of the coating. A lot of knots reduces the strength of the lathing under the metal tile, since when the formations dry out, they fall out of the body of the board.

Features of the choice of grating, the layer should not:

- sag under the weight of the roofing carpet and the person;

- contain bumps, sagging in the plane, protruding hardware (when using used material);

- have a moisture content of more than 18%.

The material of the battens and counter battens must be of the same height. If we take a separate batch of material, for example, 40 mm thick, then there may be differences of 5 - 7 mm. Before installation, boards and slats are sorted.

Choosing between wood and metal

Steel laths are more durable than wood, therefore they are used in the case of a large roof area or with a significant load. For example, iron corners, other profiles are used when installing a walk-through roof with bridges, service areas for meteorological equipment, when arranging cafes, swimming pools and other structures on the roof. The metal crate does not burn, does not rot.

Natural wood is lighter and therefore does not require strengthening of the building foundation. For construction, spruce, pine are more often used, and deciduous trunks are used less often due to the increased cost. Before installation, wooden parts are impregnated with antiseptics, fire retardants, agents against the growth of fungi and bugs. To install metal tiles on a residential building, the strength of the wood is quite enough.

Determination of the pitch of the lathing

Correct calculation prevents mismatch of metal strips during installation, eliminates deformation.

The distance between the slats is most often in the installation instructions, but there are conditions for rechecking the calculation of the step for metal tiles:

- take into account the area of the projection of the sheets on the cut of the rafters and the front board, sometimes it is necessary to lower the metal when the slope of the slope increases;

- between the first details of the lathing allow a smaller distance than between other ordinary elements;

- take into account the diameter of the drainage channel, its design.

It is not recommended, even on steep slopes, to make a crate through the step of a tile wave. This can lead to sagging of the coating and kinks in the plane.

Measurements when constructing the lathing

The size of the lattice frame is determined by the dimensions of the roof truss structure. Additionally, other parameters are measured to obtain reliable coverage.

Required to get the dimensions:

- rafter leg bar (width);

- step between individual rafters;

- the number and length of valleys, valleys, ridge;

- the number and perimeter of the outlet of heating and ventilation pipes;

- length of eaves, wind board

- the length of other junctions.

These parameters are necessary for the device of solid sections of the lathing, the selection of parts for their design. In other areas, it is allowed to install a sparse view with a step along the wave of the metal profile.

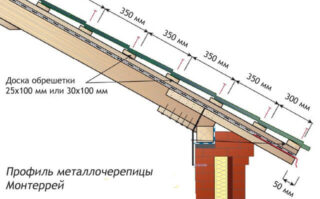

Sheathing step for Monterrey and other species

The main distances between the bars, depending on the type:

- for Monterrey, a distance of 300 mm is made from the bottom of the first board to the center of the second, and 350 mm between the centers of the following parts;

- Super Monterrey - 300 mm and 350 mm, respectively;

- Maxi - 350 and 400 mm;

- Cascade - 300 and 350 mm;

- Maxi Cascade - 350 and 400 mm;

- Classic - 300 and 350 mm;

- Quinta Pus - 300 and 350 mm;

- Quinta - 300 and 350 mm;

- Quadro Profi - 300 and 350 mm;

- Andalusia - 350 and 400 mm;

- Joker - 350 and 400 mm.

Most of the metal profiles have similar gaps for fixing the battens of the lathing.

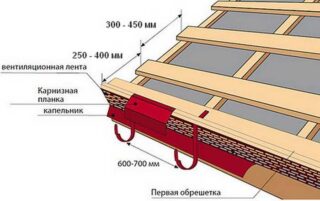

Preparing the roof for installation

They make a drawing of the layout of metal tile strips, respectively, draw up a sketch of the location of the crate parts. According to the drawings, the amount of material for the frame, insulation, waterproofing is calculated. Consider the length of the drain boxes, fixtures and connections for them.

Wooden structures are treated with protective preparations against rot, moisture, fire. Antiseptics are applied with a brush or sprayed. The products do not treat wet wood from rain or snow. For drying, wind blowers are used, sheds are erected.

Check the rafter plane to remove irregularities. To do this, use a plane, a grinder, build up pieces of the rail using brackets, self-tapping screws.

Laying the first purlins

The first element is placed horizontally along the edge of the rafter legs, fixed to the counter-lattice bar. The starting board is fixed with two self-tapping screws to each rafter. A bar of similar thickness is placed on top of it to prevent sagging of the roofing.

Operating procedure:

- measure the gap to the center of the next element from the bottom of the first;

- pull the cord between the sheathing element at the ridge and the starting piece;

- the rest of the frame boards are installed in this gap so that their upper plane touches the lacing;

- an equal distance is made between the centers of the remaining laths.

As a rule, manufacturers offer installation instructions for their type of tile, while indicating the step.

Possible mistakes and expert advice

Self-tapping screws with a galvanized layer are used for fastening, black ones are rarely used. It is better to use sharp or screw nails with a length of about 70 mm. The boards are fixed with two self-tapping screws at the top and bottom in width to prevent the part from turning out under load. The hats are slightly sunk into the wood.

On the mounted frame, there should be no protruding hardware, wire ends, which will cut the flooring of the metal tile. The ends of the bars, where the profile will bend, are rounded with a plane to prevent chafing. In concrete slabs, the slats are fixed with plastic dowels with self-tapping screws.