Decking is a floor covering made of separate boards, which is easy to install and operate. At first, the material was used for revealing the decks of sea transport, later they began to be used for the floor on open balconies, terraces, and the area around the pool. For decking (decking), a complex wood-polymer composition is used, as a result, a high-quality surface is obtained that is not afraid of harmful atmospheric factors.

Description and features of decking

The material has wood appearance, but the characteristics bring it closer to the combined polymer compositions. High-molecular compounds give products additional qualities that are not found in natural products. Lumber has long service life, they do not lose their properties for 20 - 30 years, depending on the quality of the polymers and the type of wood particles.

As part of components are present:

- wood flour, the percentage of which in the mixture is from 40 to 60%;

- a binding polymer in the same volume;

- modifying additives, pigments, plasticizers, etc.

For each application, take into account decking characteristics... For example, the floor on an exploited roof needs rigidity, and the area around the pool needs water resistance. After wood processing, secondary raw materials remain, which are used for production, polymers are also used for secondary processing. The wood in the composition adds attractiveness, and the artificial ingredients increase the quality.

Decking board copes with working conditions in a difficult operating environment, it is not affected by heat or frost. The appearance does not change, the strength does not suffer. The surface is easy to care for, maintenance includes regular annual cleaning, which does not take much time and effort.

The cost of wood-polymer boards is lower than natural wood for outdoor use, so they are available to many buyers.

Decking board types

In the construction of a wooden deck there is a floor in the open air or under a canopy, therefore all types of lumber must be biologically and mechanically durable... The requirements are due to the fact that the material is exposed to insolation, temperature extremes, and outdoor footwear is often used on the coating.

Decking can be selected of three types:

- Terrace board made of natural wood it can be smooth or grooved. They are made from the usual larch, alder, oak, or exotic species are used, for example, sequoia, ketakong, Brazilian cherry.

- Lumber from thermally treated wood or impregnated with special agents during the production process under pressure. High temperatures change the structure and improve the quality of the coating.

- Terrace WPC board... Wood-polymer composition is an analogue of thick fibrous plastic, which is more resistant to stress, and also has a beautiful appearance.

In private housing construction, all types of materials are used, depending on the owner's requirements for naturalness, durability, and a minimum of maintenance.

Characteristics and dimensions

On the back of the elements, cuts are made (compensation grooves) to reduce the influence of temperature differences, humidification. The cuts are made to a depth of several millimeters along the length of the board. It is also possible to make cuts (anti-slip) from the face during installation to reduce the smoothness in case of wetness. Boards are not placed in a tenon, since there are always slots of the correct size between them.

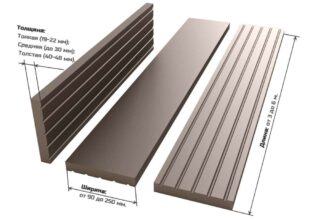

By thickness produce terrace boards:

- thin placed in places where a decorative platform is needed without significant loads, their thickness is 19 - 22 mm;

- to middle include elements up to 30 mm thick, used in coatings with normal efforts from the weight of people, furniture;

- thick installed on the planes where cars pass, park, heavy objects, equipment are located, their parameters are 30 - 50 mm.

Thick elements are not used if piles serve as supports for the site, since a deck of this size creates a significant load.

The width of the lumber depends on the square of the floor. For an area up to 6 m², a width of up to 110 mm is chosen, terraces in the range of 6 - 20 m² are finished with a width of 110 - 180 mm, and over 20 m² - 180 - 250 mm.

Texture and color scheme

The materials for decking are the same types of wood as for conventional flooring. Budget options are performed with inexpensive pine, but such a surface needs to be treated with impregnations from time to time. Preference is given to dense and hard wood.

Varieties of texture:

- planken (smooth surface);

- corduroy (corrugated).

Quality material is produced in 10 color options, it is distinguished by a flawless flatness without burrs, chips, and other small deformations. The decorative characteristics of various types are different, and the colors of natural boards and WPC material are also not similar. Manufacturers color and tint natural material, lighten and darken, and for artificial lumber, the palette is somewhat limited.

Sell decking paints different price segment. The surface color can be changed with compositions based on ethyl, alkyd and organic solvents, oils and wax.

Criterias of choice

The main condition is floor use option, the type of coating, load resistance, equipment with fasteners depends on it.

Various options:

- Home Standart. For use in private areas with low traffic.

- Proffessional. The covering based on polyethylene, propylene is installed in public premises.

- Expert. The material has a high load-bearing capacity, therefore it is installed in places of high traffic and in parking lots.

Don't buy inexpensive types of deckingas the products may be counterfeit. When buying, they require a quality certificate, documents of compliance with international standards. What matters is the visual homogeneity of the structure, the absence of even a slight waviness.

Application area

The material is intended for floor cladding in open spaces... It is used by designers on terraces of a simple and complex shape, they decorate the landscape around water bodies, on piers, private piers, in the park area of the site.

Decking is successfully mounted inside the house, they are lined with garden paths, approaches to the porch, some craftsmen decorate the walls. The material is used where a decorative look and durability is needed outdoors.WPC boards with improved properties are installed in baths and saunas.

Installation Basics and Tool List

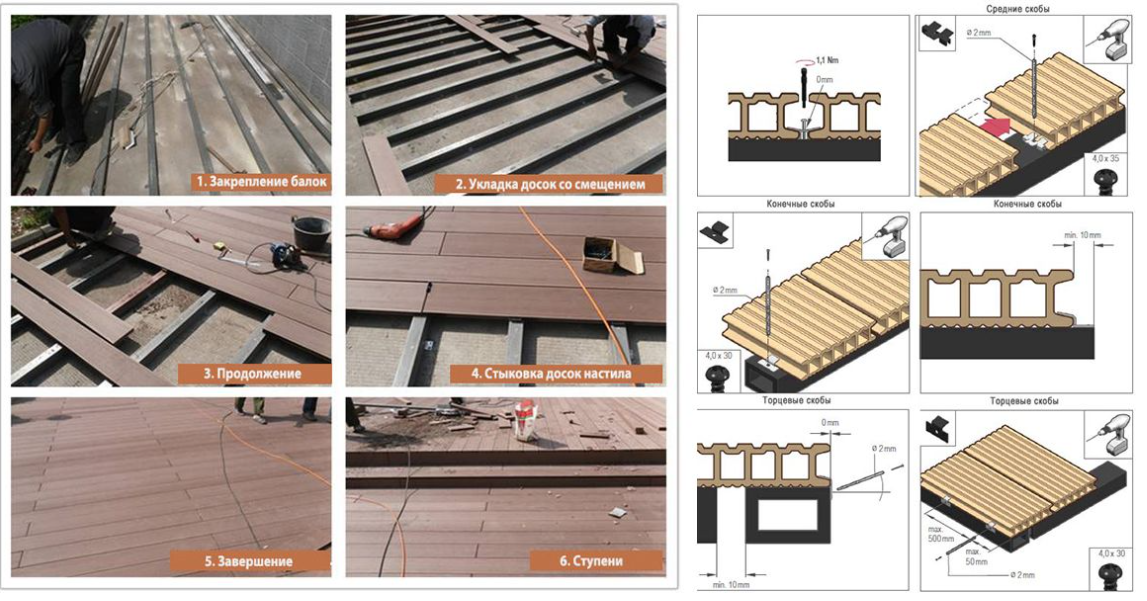

Decking board set open and closed method... The first method is suitable for do-it-yourself installation, since it is simple, while there is savings on fasteners. The price of installation by an open method is 2 times lower than installation with clamps.

Open mount on nails has disadvantages:

- subsequently, the gaps between the boards will increase, and the screws will not hold the elements in the desired position;

- the holes sealed with putty look ugly.

Closed version use fasteners that are pre-installed on the top or side surface of the log. The result is a smooth, attractive surface, the elements of which do not move.

For mounting you need tools:

- measuring and control devices: tape measure 5 m, level, carpentry corner, cord for stretching;

- a set of screwdrivers, a screwdriver, an electric drill, a jigsaw;

- hammer, saw on wood.

Fasteners are divided into types according to the method of attachment: groove, track, spike, lock. The last option is considered the most reliable, but the installation speed slows down. Only low-density material is placed on the spike fasteners, the groove one is distinguished by an additional selection of grooves on the back side of the boards during installation. The track view provides a solid hold, but requires some dexterity.