Polymer plastic panels are durable, attractive appearance and lack of any visible traces of installation. Additional elements for siding play an important role in creating high-quality, beautiful and durable flooring. To achieve the desired result, it is necessary to understand the types, purpose, sizes of additional elements of vinyl siding, as well as to carry out the correct calculation of their needs.

Why do we need components

Finishing panels are designed to create a facing surface, decorate an object of a particular configuration, protect it from external factors and mask defects. In this case, the planes created have internal joints, form corners, edges, they have window and door openings.

Siding components used in the cladding of buildings are used to perform the following tasks:

- Giving the canvas a finished and neat look. Creation of harmony of all details. The use of contrasting colors creates an interesting and original visual effect.

- Giving the structure additional strength and solidity. Additional siding elements have grooves in which fragments of the canvas are attached.

- Closing the ends of the panels, their sealing, protection from the penetration of insects and animals.

- Ensuring the static plane of the finish. Prevention of deformation of the finishing material.

- Decrease of vibration level of the deck under strong wind load.

Siding panels are made from the same material as the lamellas. With their help, you can beautifully and efficiently finish a surface of any size and complexity.

About varieties and purpose

The finished surface is made to imitate the following walls:

- log;

- timber;

- ship board;

- natural stone;

- plaster;

- brickwork.

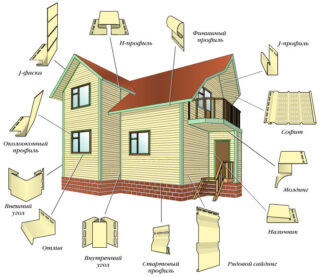

Complementary parts are divided into the following categories:

- For wall decoration. They are used to connect planes that are relative to each other at different angles, to close edges and ends. They form such structural elements as overhang, cornice, facade. There are docking, corner, initial and finishing profiles.

- For framing doors and windows. Elements are used to decorate openings, sometimes without fixing panels for thin walls. To beautifully and reliably seal the recesses, platbands, window sills, chamfers, a window strip, internal and external corners are used.

The main condition for achieving a high-quality result is the purchase of panels and strips from one manufacturer, the use of high-quality components for their intended purpose. Experts recommend making a metal frame that resists changes in temperature and humidity better than wood.

Why you need to consider sizes

Correctly carried out measurements will allow you to accurately calculate the need for material, after the end of the work there will not be a lot of surplus, and the process itself will not stop due to the fact that there were not enough extras.Knowing the length of the planks will allow you to plan everything well, sheathe knowledge without delays and stumbling. When purchasing material, you need to provide for a small reserve within 10-15%. During the installation process, mistakes are not excluded, the original intentions may well change.

To get a complete picture of the upcoming construction, you should make a detailed drawing of each side of the building, add to it schemes of openings, overhangs, other protrusions and recesses. The height, length of walls and individual elements are the initial data for calculating the number of planks. For each direction, they must be selected separately, rounding the fractional results to the size of one part. It is better to use whole slats, since such structures look much better, and their performance is higher.

Calculation of components

After taking measurements and familiarizing yourself with the range of products available for sale, you can proceed to practical calculations. Their independent implementation does not cause difficulties, provided that not a single trifle is missed.

You can use the following algorithm for calculating the need for extras:

- Starting (initial) bar. Here you can calculate for each wall separately or divide the perimeter by the size of one unit with rounding and adding a margin. It is more expedient to count individually, since the trims can be precisely adjusted.

- Internal and external corners. The total length of such structures is measured and divided by the length of one unit. Can also be calculated separately by trying on leftovers and trims to the remaining gaps.

- Window and door strips. Counting is carried out for each opening separately. Not only external but also internal angles with different values are taken into account. Here you need to knock everything out so that all the edges are solid.

- Connecting profiles (H-shaped). Their number depends on the number of joints. As a rule, there is rarely more than one seam on one wall. Based on this, the required number of strips is purchased.

- Finishing rail. In most cases, the number of units corresponds to the starter items. If the building has an asymmetrical shape, then the calculation is carried out separately.

- J-shaped profile. It is used to close all diagonal connections on walls and eaves. Also, the total amount should be slightly higher than according to the schemes.

Please note that many sellers have their own part designations.

What leads to misuse

Thanks to sophisticated technology, laying siding is a fairly simple undertaking. However, even here beginners can make mistakes. The use of material that does not meet the proper criteria and the violation of the rules for its installation leads to the following consequences:

- leaks at the joints;

- large cracks where birds and insects penetrate;

- strong rattling in the wind;

- destruction of the coating under the influence of thermal expansion;

- deformation of the planks, the appearance of cracks:

- departure of the finish from the base under the influence of internal stresses.

All this can be easily avoided if you follow the manufacturer's instructions and the recommendations of experienced craftsmen.

Only quality products should be used to sheathe a building. You need to buy it in large stores and only after checking the availability of a quality certificate. All parts must be inspected for clarity of shapes, color uniformity and absence of mechanical damage. It is mandatory to complete the transaction by receiving a warranty card.