Primary woodworking products have an unattractive appearance, but also find their niche application in construction. The material is inexpensive, therefore it is used for auxiliary work, when the requirements for the type of coating are reduced. Designers use rough lumber to create interesting looks. An unedged board is made from deciduous and coniferous wood.

What is an unedged board

The material is boards with partially sawn or whole side edges, wane takes place. Lumber is made from soft and hard wood, while its natural structure is preserved, as is the chemical composition. Trimmed elements are obtained from felled trunks or their pieces by transverse or longitudinal sawing.

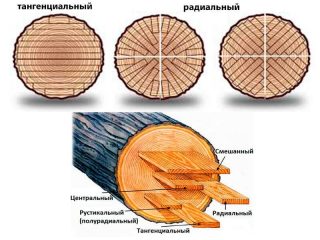

Products are subdivided depending on cutting places from the trunk:

- core boards - parts taken from the central core of the log, the structure includes a solid key rod;

- central - any of two adjacent elements, cut from the central area of the log, located in a symmetrical form;

- lateral - parts obtained from the marginal sections of the trunk.

By humidity there are several types: raw with a moisture content of 22% and above; dry unedged boards - up to 22%; raw with an antiseptic.

How is it produced

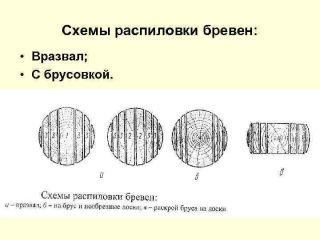

Use techniques:

- Sawing wobbled. The trunk is divided in one procedure on a band sawmill, a multi-saw unit into several edged boards of a given thickness.

- Sawing with timber. At the first stage, several side boards are cut out of the trunk, at the same time a middle bar with two edges is formed. At the second run on the same machine, the timber is divided into unedged elements and edged ones, the edge of which has fallen into the lumber surface.

In the production of unedged varieties, they take second and third stem cutswhich are classified as lower quality raw materials. More often the board has dimensions in thickness 25 - 50 mm, the width varies within different limits and depends on the thickness of the tree. Thanks to this technology, low cost of production.

Difference from edged

Trimmed material passes processing on four sides, it is distinguished by perpendicular adjacent faces.

Such characteristics classify products as universal category:

- the result is a dense layer without gaps;

- there is no bark and wane on the surface, which prevents the appearance of fungi, the reproduction of insects, microorganisms:

- the width of edged sawn timber is always 2 times greater than the thickness, the shape of the products is a rectangle;

- the outer plane has an attractive appearance, and the material is used for sheathing with an unedged board of the floor, walls, furniture, and other front work.

Unedged the board differs in that there is bark on the edges... The material is used where there are no high requirements for the aesthetics of the structure. On the surface, defects are allowed in the form of fungal infection, mold, rot, fallen out and loose knots, heterogeneity of color, dark spots.

Varieties and scopes

Products are distinguished by sorting method:

- machine sorting is carried out by mechanisms, focusing on the mutual dependence between the indicators of elasticity, tensile strength, compression, bending;

- visual rejection by external inspection, taking into account the number of defects, the size of the lumber, the location of the knots.

there is trimmed raw boardwhen elements are cut to length to a specific size. The second kind - not trimmedwhen the material has a barrel length.

Also distinguish unedged carpentry board and fences elements.

Products are used depending on the purpose, overall dimensions and raw wood species.

Wood species

For manufacturing take spruce and pine... Spruce contains less resin, but insulates the surface well, and pine is used in humid conditions. Raw cedar elements are rare.

Features of coniferous boards:

- will serve for a long time as a fence or fence;

- do not give significant shrinkage;

- protect well from cold;

- easy to handle at home.

Boards are put for formwork while pouring concrete, in the manufacture of scaffold boards on the scaffolding. An interesting view allows you to use the material for the construction of the walls of summer cottages, awnings from the sun.

The material is set as temporary overlap, bridges between building structures. The fence looks beautiful in combination with brick, stone, decorative elements in the form of natural elements.

The cost products depend on the quality of sawing, species, processing technology. When choosing, the percentage of moisture, color plays a role.

There is a chance to find on sale a board from larch or oak... Such materials are least susceptible to decay. Larch and oak have almost the same hardness.

Larch board:

- does not absorb water;

- acquires additional hardness;

- fungus and mold do not form in humid conditions;

- the special composition of resins scares away insects and rodents.

Unedged hardwood on the roof of the house helps create a comfortable indoor microclimate. Such wood skips pairs, so there is no thermos effect.

Unedged material from linden, aspen, alder, birch rare if there is an order for such a variety. Hardwoods are used for the construction of pavilions, sheds. The material is combined with a log house, lumber of a different color and shade.

In summer annexes install impromptu picturesque tabletops, make stylized platbands around window and door openings in log buildings, huts... From the planed layers of unedged boards they arrange sandbox framing.

Dimensions of unedged board

The board must have the correct geometry, not warped. Such consequences occur with improper drying of the material. Finding an application for curved unedged products is very difficult.

Element sizes:

- thickness - from 20 to 50 mm;

- width with one cut off side and two from 70 mm, with a graduation every 10 mm;

- the length ranges from 0.5 m to 6.5 m (hard), from 0.5 to 2.0 (soft material).

There should not be too many chips, through cracks, falling out or rotten knots on the board. Such defects significantly reduce strength, and for formwork it is irrational to install defective fences.