Edged board 25x150x6000 is one of the most demanded building materials. Products are used at all stages of construction support and for the construction of independent structures. Lumber is chosen taking into account the purpose and required properties.

Features and varieties of edged boards

- exact geometrical dimensions:

- no waste when used in construction - the side edge is flat, without wane;

- strength;

- ease of processing;

- flexible price, depending on the grade of products and wood species;

- durability with appropriate processing;

- versatility;

- low price;

- environmental friendliness.

disadvantages are manifested in the case of incorrect selection of products based on the operating conditions and purpose, as well as with a careless attitude to the processing of products, intended for outdoor installation.

Classify varieties of edged boards follow several signs:

- wood species;

- grade;

- method of processing.

Regulatory documents provide for the production of edged boards from coniferous trees: pine, spruce, fir, larch and cedar.

Hardwoods are rarely used for the manufacture of boards with a diameter of 25x150 and 50x150 and a length of 6000 mm. This is due to the value of the species (oak, beech, hornbeam) or low consumer properties in construction (birch).

Finished products are distinguished and by processing method:

- direction of sawing;

- not planed can be raw or dried;

- planed products have a smooth surface on all sides and can only be dried;

- tongue-and-groove boards are used for flooring or wall construction in frame buildings.

All information required by the buyer is indicated in the symbol. For example, "board - 2 - pine - 25x100 GOST 8486-86»Denotes pine products, 2 grades, with a cross section of 25x100 mm, produced in accordance with the requirements of GOST.

Main characteristics

With minor amendments, the two guiding documentsthat determine the technical characteristics of products:

- GOST 8486-86 for coniferous boards;

- GOST 2695-83 for products from deciduous trees.

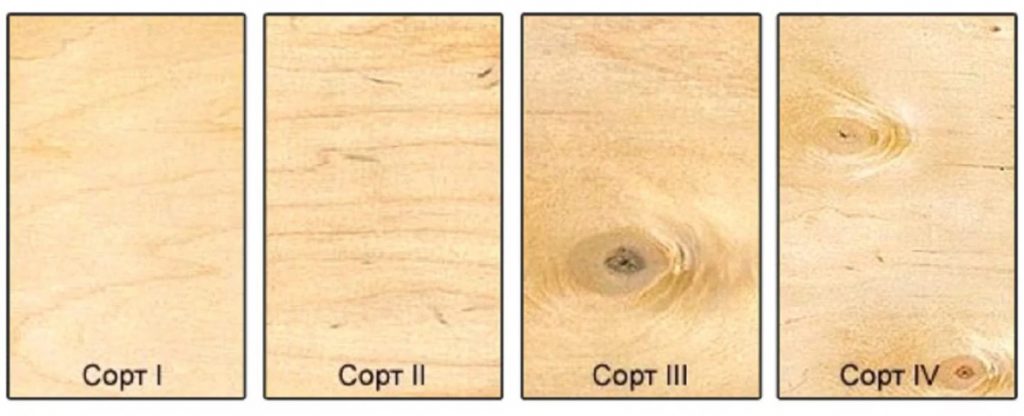

GOST for coniferous sawn timber provides for a division into 5 varieties, and deciduous 4 varieties.

Selected the material does not allow more than 2 intergrown healthy knots and 1 one-sided pocket with resin on each meter of the board. The presence of roll (darkening of tree rings), cancer, rot, fungus, sapwood fungal color, mold and foreign inclusions is prohibited.

Varieties with first to third allow, to varying degrees, the presence of intergrown and falling out knots, cracks, resin pockets, wood defects, except for rot.

Lower, fourth the variety allows the presence of a small amount of wane and rot. Such products are used for the manufacture of non-critical structures that are dismantled at the end of the work, for example, formwork and scaffolding.

Some manufacturers set their own designations for product varieties; information must be checked with the seller.

GOST allowed within 3-5 mm deviations from the declared geometric dimensions, as well as the roughness of products. Strength and resistance to destruction are not standardized by documents.

Choice boards, grades 1, 2, 3 are supplied dry (moisture content up to 22%), raw (above 22%) and moist antiseptic.

From May 1 to October 1, raw material can only be supplied by agreement with the customer.

Scope of application

Board 50 x 150 mm is universal in use and is successfully used in the spheres:

- frame construction - a base is erected from the boards, which is subsequently sheathed on both sides.

- arrangement of internal partitions capable of bearing the load;

- manufacture of roof systems;

- furniture production;

- flooring;

- production of bodies of machines and units, rolling stock of transport.

- special shipbuilding;

- manufacturing of parts for agricultural machinery;

- car building and auto building;

- construction and repair, manufacture of window and door frames.

The third and fourth grades are suitable for the production of containers and packaging, unimportant parts in construction.

Estimated prices

Depending on the region, prices for sawn timber vary greatly due to the transportation costs of delivering products from producer to consumer. The cost is influenced by the grade and type of wood.

Prices for a cubic meter of a board 25x150 and 50x150 do not differ.

In one cube, there are 44 pieces of 6-meter boards with a section of 25x150 or 22 with a size of 50x150.

The average wholesale selling price is kept within 8500 rubles / m³.

Approximate retail prices for pine sawn timber.

| Product | Price, rub / m³ | Unit price, rub. |

| Edged board 25x150x6000 mm | 7500–12000 | 170–270 |

| Edged board 50x150x6000 mm | 7500–12000 | 340–540 |

Dry material can cost 25-30% more.

For the construction of formwork, substandard material is purchased at a cost of 5000 rubles / m³.