For covering open areas, terraces, verandas, gazebos in the garden, instead of ordinary boards, special ones are often used - terraced ones. The latter can be made from ordinary wood, from heat-treated wood, and also be products from wood-polymer conglomerate.

Description and types of WPC

Boards are made in an unusual way. The raw material for them is a mixture of fine sawdust and thermoplastic polymers... This composition determines the appearance of the qualities inherent in wood and plastic. At the same time, the finished product is usually devoid of their disadvantages, such as susceptibility to fungi, instability to moisture.

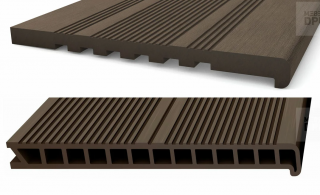

The advantages of decking are due to the material and the device. Board with cavities inside does not accumulate moisture in any form... Even when the terrace is flooded, water will flow through the cavities, as if along a gutter. therefore platforms are always tiltedso that the water can drain. Water resistance, non-susceptibility to decay is provided by the plastic in the composition.

The surface is rarely made smooth, as it becomes too slippery when wet. The embossed pattern gives the boards an attractive appearance and provides a good grip. The similarity to wood - color and pattern - is due to the top decorative layer - thermal film, glued to the board.

Structure

- wood flour - finely crushed sawdust, as well as sunflower cake, waste paper, husk and other plant waste;

- polymer - polyethylene, polypropylene, polyvinyl chloride;

- modifiers - their content does not exceed 1–5%, they improve the technical characteristics of the decking.

Production

Distinguish one- and two-stage production. In the first case, the dry ingredients of the composition are mixed with plastic granules. In a two-stage, a granular mass is made. As a result, the quality of decking is determined by the qualifications of the technologist, since the latter needs to adjust the unit so that different temperatures are maintained in different parts of it.

The WPC blank has a smooth, slippery surface that is not scratch resistant - this is impractical. Boards are processed in different ways.

- Grinding - the top layer of the product is compacted and sanded to smoothness.The piece is then fired and often embossed to give it a wood-like texture.

- Brashing - with special hard brushes they remove the unstable glossy layer and form the original structure. This method is often used to mask geometry that is not too accurate.

- Embossing - thermal stamping. It is carried out on solid boards, since hollow boards cannot withstand such loads. The texture completely repeats the woody pattern.

Finished products are packed in foil and sent to the warehouse.

Specifications

Decking properties depend on the composition. Wood-polymer composite has the following characteristics:

- density - 1.2 g, sq. cm, but this figure is set for a hollow board;

- specific weight - 2.5 kg;

- moisture absorption - no more than 5%;

- wear and abrasion - no more than 0.1 g / cm²;

- mechanical strength - the permissible load reaches 550 kg / cm²;

- working temperature - from -45 to + 70 ° С;

- fire safety - the material belongs to the G4 flammability class, that is, it ignites poorly and self-extinguishes;

- frost resistance - withstands up to 150 complete cycles of freezing and defrosting;

- lifetime - 25 years.

The weight of the board depends on the size.

More about the advantages:

- WPC boards are used for flooring not only on the terrace, but also on berths and decks. This floor can accommodate heavy furniture and equipment.

- When making a board, the sawdust is enveloped with a polymer melt, which protects the material from bacteria and fungi. Terrace boards do not need to be varnished or painted.

- In houses on the coast, decking is often used for flooring inside the house.

- The material is easy to cut and assembled by the “thorn in the groove” mechanism. You do not need high qualifications for installation.

- The top layer of the product is compacted during processing. Splinters and injuries are excluded.

Varieties of material

WPC material determines the quality of the board. His properties depend on the composition of the initial mixture... On this basis, distinguish 3 types.

- 70% wood flour and 30% polymer - the material acquires hydrophilic properties. He is not afraid of direct contact with water, steam, dampness. However, at high humidity, the material swells somewhat. This reduces the time of use in damp climates.

- Wood shavings 40% and 60% plastic - more a plastic material than wood. Compared to plastic products, it retains heat slightly better.

- Wood flour and polymer in equal proportions - is considered the best option. The material does not swell even at high humidity, but at the same time it feels like wood to the touch, retains warmth and beautiful appearance. The service life is maximum.

By there are 3 types of binder:

- polyethylene - cheap, but not resistant to ultraviolet radiation, material quickly fade;

- polypropylene - better tolerates the sun and temperature changes, and most importantly - it is very resistant to wear and tear;

- polyvinyl chloride - combines all the positive qualities, but much more expensive.

Information about the type of binder is indicated in the decoding of the code.

By invoice the outer surface of the board is divided into 2 types:

- smooth surfacereproducing the pattern and texture of the bark;

- grooved or anti-slip - a series of vertical anti-slip protrusions are formed on the front side, which ensure complete safety.

When choosing the type of material, its density must be taken into account. The indicator of 550 kg / cm² is characteristic only of high-quality decking.

Scope of WPC

When developing decking, the main task was to create a material that is cheap enough, but resistant to moisture. The resemblance to a tree in this case is due only to the popularity of the latter. Decking can just as well imitate stone cladding. Planks were developed for arranging open areas and paths in the garden. However, their characteristics turned out to be so interesting that decking became much more widespread.

Cladding

WPC boards are perfect for facade finishing. They are resistant to moisture, frost-resistant, easy to install. Especially for cladding the walls of the house from the outside, the following are produced types of panels:

- in the form of siding - there are no voids in such slabs; in terms of properties, they most of all resemble polypropylene facade decoration;

- hollow - with a cellular structure that removes moisture;

- rack - narrower boards without voids;

- planken - solid boards with grooves for clips, very easy to assemble;

- lining - reproduces wood finishing boards.

Installation is carried out in the same way as clapboard or siding.

Floor

Choose material by size.

- Length - from 1.5 to 6 m. Long ones are used for arranging piers and piers, dance floors. It is better to put short boards inside the dwelling - they look more aesthetically pleasing.

- Thickness - from 18 to 48 mm. This indicator determines the strength of the board and the value of the bearing load.

- Width - from 90 to 250 mm.

There may be others as well. It depends on the manufacturer, as well as on the method of joining the rails.

Walls

As a rule, boards that imitate wood are chosen. However, there are also more decorative materials that reproduce rack sets.

Windows and doors

WPC is a quite suitable material for the manufacture of interior doors and windows. It can withstand a very high load. Glazing, even triple glazing, is not a problem for the frame. At the same time, the material reproduces the pattern and color of the wood and looks beautiful.

The rigidity of the door or window is provided not by plastic, but by the frame. In this sense, WPC products are no different from a metal-plastic profile.

Furniture

Made of material benches, sofas, tables, chairs, swings, couches etc. Take both hollow and solid boards. It depends on the size, and not the purpose of the furniture, since there is enough strength in abundance.

The surface of the furniture deck is smooth or reproduces the texture of wood. No special relief is needed here.

Terrace board

- corpulent - no voids, more durable, designed for high bearing loads;

- hollow - used for arranging verandas, terraces and other structures where it is important to ensure the outflow of water.

Terrace boards are used for covering open garden areas, for arranging the yard, laying garden paths. Perfect material for organizing the area around an indoor or outdoor pool.

WPC manufacturers

- Ligna tek Is a well-known Russian company. The first launched the production of decking in Russia. Produces decking in several colors and sizes.

- POLYWOOD - produces terraces according to its own patented technology. The boards are available in 3 shades.

- DORTMAX - offers products in the middle price segment.

- WERZALIT - produces a hollow and full-bodied board.

- DeckMayer - a German company that offers not only terrace, but also facade boards for building decoration.