Oak is a valuable expensive wood with a mass of extraordinary qualities. Oak board is not afraid of dampness, water, steam, it is distinguished by exceptional strength and durability. In addition, the material is beautiful, so it is readily used for decoration and in the manufacture of furniture.

Description and varieties of oak boards

Material properties depend on the time of cutting, the method of processing, the degree of humidity and the conditions in which the tree grew.

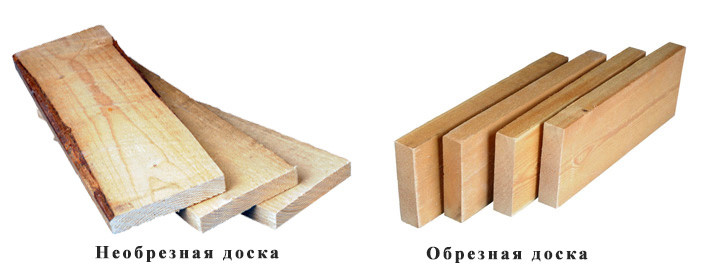

Edged oak board - the product is cleaned from all sides of bark, knots, podzol. The surfaces are cleaned mechanically. It turns out not smooth, but very even. Such material is used for rough and final finishing of the floor and walls, for the production of furniture, for the construction of stairs, partitions.

Unedged - oak planed board is cleaned and leveled only from 2 sides. It is somewhat rougher and rather serves as a blank. This material is used in furniture production, in joinery, as well as for the construction of fences and frame structures.

A very important parameter for wood - moisture degree... The more moisture, the greater the shrinkage of such a tree. This parameter is distinguished 2 types.

- Boards with natural moisture - from 25 to 40%... The material obtained immediately after cutting the trunk contains so much moisture. You cannot immediately apply them for anything. The lumber is dried for 6–8 weeks. After the initial drying, the tree is sorted and decided what to use.

- Dry - humidity is 6–8%... The material is dried in special chambers or naturally - in closed sheds and warehouses. The latter option takes more time, but is considered more effective, since the natural loss of moisture is accompanied by natural shrinkage.

Another classification is associated with wood quality... The elasticity, hardness, strength of oak depends on the place where it grew.

- Stone wood - dense and firm, but not elastic. The material is obtained from trees grown on sandy soils. The wood is very light and fine-grained.

- Iron - prone to chipping and cracking, but elastic and very beautiful. It is obtained from oak trees that grow in areas with high humidity. This is the most expensive type of wood.

- Intermediate - has a very beautiful pattern and a characteristic honey tint. The wood is obtained from trees growing in mixed zones.

Most often, boards are made from the latter type of oak, since it is the most common.

Applications

- floor - more often parquet than plank flooring;

- finishing wall panels - decorated with carvings are especially effective;

- ceiling elements, especially coffered ones;

- furniture - is distinguished by the most noble appearance and elegance;

- doors - both entrance and interior;

- decorative items - boxes, chests, candlesticks, household and interior items;

- works of art - carved panels, sculptures;

- staircase structures.

Oak is often used and for baths cladding... The wood is beautiful, withstands steam and has healing properties.

Estimated cost

Many companies offer oak lumber. The cost depends on the nature of the wood - stone, iron, from the type and method of cutting. Excluding customs duties, material from Italy and Russia is approximately the same in value.

- Amber wood Is a Russian company. Offers massive oak planks for 3900–5000 r. for 1 m².

- Amigo Is a German company. Its boards cost 4000–5000 rubles. per m².

- Ital parchetti - Italian production, offering parquet and solid boards for 3500-4000 r / m².

- Coswick - the products of the Canadian company cost from 4000 r / m².