Steel I-beams are one of the most common types of rolled metal products. It is widely used in construction, for example, when arranging various kinds of support structures, and can withstand higher loads than a channel and a corner. To choose the right product, you need to study the assortment of I-beams and be able to calculate the loads.

I-beam concept

In accordance with GOST, products are manufactured from carbon and low alloy steels... Produce them and made of aluminum - such profiles are acquired when low weight is important for the structure.

The standards govern a number of rental characteristics: for example, wall deflections should not exceed 0.14 S, and maximum permitted beam curvature – 0,2%.

When purchasing material, it is recommended to study certificates and other accompanying documents to assess whether it is suitable for the tasks at hand.

Stands out 2 production methods of this material:

- Hot rolled are made from steel ingots by pulling heated blanks through a machine with a roller. The slope of the inner edges of the shelves for such products should not exceed 10%.

- Welded the product is made from several pieces of metal sheet. At the same time, manual labor is used to a minimum, the main processes are provided by automated lines.

The production of hot rolled products is faster than welded products. Another plus is that there are no welds, which minimizes the likelihood of corrosion. The load-bearing qualities are good for both types of material. Due to their lightness, the products are easy to assemble. The shelves distribute the load in a way that minimizes the risk of skewing.

In low-rise construction, it is used and wooden I-beam... This is a combined product consisting of solid wood and pieces of OSB boards. It is used as a carrier in rafter systems and for arranging under-roofing rooms.

Classification and scope

By rolling accuracy I-beam is subdivided into normal (denoted by letter B) and with a high value of the parameter (letter A).

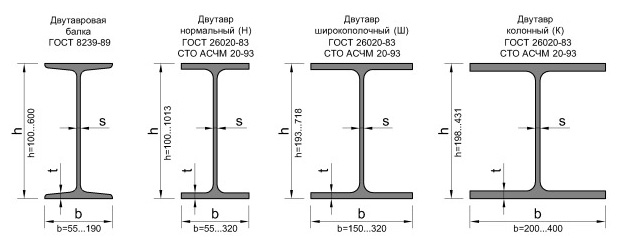

According to the purpose and structural features of the profiles are of several types:

- Normal I-beams - the height exceeds the width of the shelves. They can be used in all major applications of this profile.

- Column I-beams used as vertical support elements in the construction of multi-storey structures. Their shelves are parallel to each other and have increased thickness.

- Wide shelf I-beams are intended for structures that work primarily for bending: bridge structures, staircases, floors. The variable cross-section increases the bearing qualities of the metal structure along the entire length. The use of such products also helps to save money (production costs are lower). When purchasing products, it is important to consider the thickness of the shelf.

- Profiles for overhead tracksfor which special requirements are imposed. The inclination of their inner edges should not exceed 12%.Such products are in demand in the arrangement of some industrial enterprises. Their profile can have a height of 0.25-0.45 m.

- Pile profiles with increased bearing capacity. They are used for components of structures working in compression (sometimes in combination with bending) and tension.

I-beams are widely used in different areas of construction:

- construction and reconstruction of buildings

- supporting elements of bridge structures and overpasses;

- crane beams in industrial and warehouse premises;

- when arranging mine passages as a reinforcing component;

- when creating roofs;

- span beams in buildings of any purpose;

- to limit the pit during foundation work;

- for fastening floors.

Range according to GOST

The current GOSTs for I-beams provide for certain markings. The standards prescribe the mass of the product depending on its linear dimensions.

GOST R57837-2017 regulates the dimensions of the I-beam of the following types:

- beam,

- columnar,

- pile,

- wide-shelf.

The first two varieties come in two forms - regular and additional... According to this standard, I-beams can have a height from 10 to 71 cm and a shelf width from 5.5 to 26.2 cm. The thickness of the vertical part is from 4 to 17 mm, and the thickness of the shelves is from 5.1 to 25 mm. The I-beam weight of this brand varies from 8.1 to 194.8 kg per running meter. The weight of the product, as well as the maximum permissible load on it, depend on the dimensions. The most compact among the beam products is marked 10B1 and has a height of 10 cm. Its weight is 10 kg, and the maximum load per section is 16.512 tons.

Height of column I-beams - from 14.7 to 66.8 cm, shelf width - from 14.9 to 43.5 cm, its thickness - 15-43.5 mm. The minimum weight per meter of such a product is 26.8 kg (this is an I-beam 15K1 with a cross-section load of 54.762 tons).

Having studied the included in Gosstandart I-beam weight table of different brands, you can choose an option suitable for a specific task.

GOST 26020-83 considers the same types of products with the exception of the pile. Additional options are available for beam and wide flange profiles. When considering the numerical values, some differences from the previous standard are found: for example, this GOST includes large-sized beam products, the dimensions of which are beyond the scope of GOST 2017 (height up to 101.3 cm, meter weight up to 314.5 kg).

There is also a variety of I-beams. profiles with an inclination of the inner shelf edges of 6-12%... Its manufacture is regulated by GOST 8239-89... The fillet at the junction with the wall increases the strength of the product. This is one of the most popular types of such a profile.

- shelf width;

- profile height;

- radius of curvature of the shelf edge;

- the thickness of the middle vertical part and the shelf;

- moments of resistance and inertia.

Preferred I-beam parameters depend on the characteristics of a particular structure. The following characteristics are taken into account:

- distance between the ends of the supports;

- type of load and its meaning;

- the material from which the beam elements are made;

- distribution of force (focused at one point, evenly distributed over the surface, etc.).

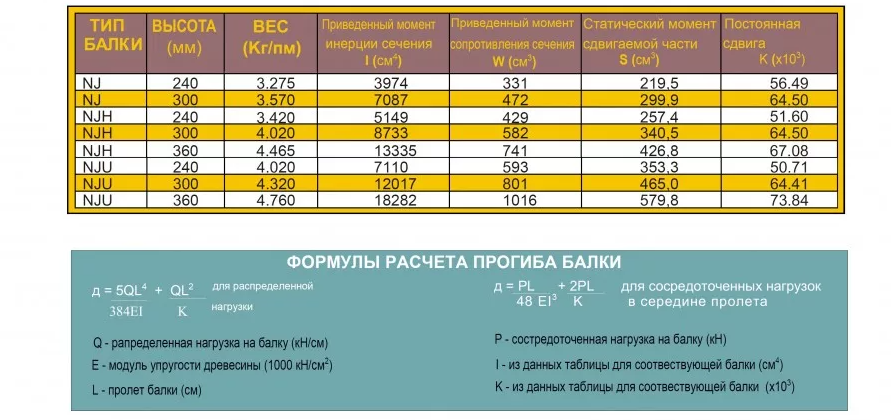

Calculation of I-beams

One of the important characteristics to consider is beam fixing type in combination with the distribution of the load on it. Most the following types are common:

- hinge-supported structures - the load can be distributed evenly, or be concentrated in one or two areas;

- option with rigid termination of one of the ends and uniform load distribution;

- version with one span, one-sided console, additional support and even distribution of force;

- rigidly terminated cantilever with a single-point focused load.

It is also necessary to calculate total load acting on the building... It includes several types of components. Constant load (in the case of a conventional interfloor beam in a residential building) create the mass of the element itself, the floor and the cement screed, variable - for example, snow and pieces of furniture. Having calculated the total amount, it is multiplied by the safety factor (it depends on the type of I-beam and is most often equal to 1.2 or 1.3). The resulting value must be used in the future.

To select the size of the profile, you can use table, which gives recommended numbers of beams depending on the total load, span length and spacing... For example, at a pressure of 300 kg / m² and a three-meter span with a step of 1 m, you can take profile No. 10. For large values of load and length, the number of the I-beam will also be larger.

Another way is select the moment of resistance according to the table valuebased on the total weight multiplied by the safety factor. By its value, you can also determine the recommended profile number for the assortment. For reliability, it is better to take an I-beam 2 numbers larger than the resulting one.