Epoxy tile grout is used to fill the joints between trim elements. It gives the lined surface a more aesthetic appearance. It has waterproofing properties, so that moisture will not seep into the gaps.

Description and material properties

Epoxy grout can have various shades - from transparent or light gray to bright and shiny. This simplifies the selection of the color that best suits the tile or mosaic.

Composition and characteristics

Mixing the product requires adherence to technology and proportions (for each grout, they are given in the instructions or on the package). Special dosage accuracy is important: if, when preparing a cement mortar for masonry, small errors will not be critical, then this should not be allowed with epoxy putty.

Among the main properties product can be distinguished:

- waterproofing: the composition is waterproof and does not allow moisture to pass into the gaps between the tiles;

- plasticity of the structure, no tendency to cracking and accumulation of dirt;

- color stability and uniformity;

- resistance to chemicals, including many aggressive ones;

- good tolerance to ultraviolet rays and temperature fluctuations.

The seams, made in compliance with the technology, retain their attractive appearance for a long time. The service life of grout tiles can be more than 20 years.

Scope of application

Due to its water resistance and resistance to reagents and other chemicals, it is well suited for bathroom, pool, balcony, car wash, workshop premises.

Epoxy grout can be applied for mosaic, including as an adhesive.

How to choose a grout color

If it was not possible to find the desired shade, you can color the white grout by adding a combination of pigments to it. This can be done only in the process of mixing the composition. You cannot change the color of an already applied putty.

Sometimes colored sand or shiny particles are added to the mixture.

Some buyers prefer shades, as close as possible to the tone of the tiles, others - contrasting colors for zoning or adding variety to the decor.

For finishing small room you can choose a grout tone that matches the lightest color in the tile pattern, for spacious room - on the contrary, the darkest. Sometimes the shade is chosen based on the existing pieces of furniture.

Application rules

Some brands of tiles edges may darken when in contact with all kinds of liquids. Therefore, the day before the procedure it is recommended to test the product to the tendency to such a reaction. If you find it, you will have to be careful cover the sides with masking tape at the time of applying the composition.

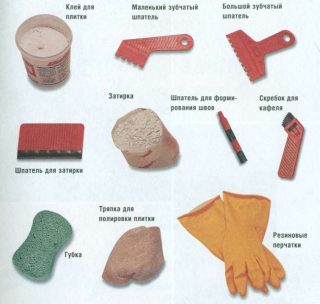

Required tools and materials

- a drill with a mixer, which will mix the composition;

- a grater with a spongy part made of rubber;

- bucket and spray bottle with water;

- mixing container;

- well-tuned scales;

- latex gloves;

- special tool for removing grout;

- cellulose sponge for cleaning surfaces from composition residues.

Solution preparation

The mixture is prepared from resinous and curing components by simple mixing. In packages on sale, the necessary proportions of the two components are often already taken into account.

The mixture is characterized by fast solidification - its must be consumed within an hour after preparation... After this period, it will no longer be operational. Therefore, before mixing, you need to find out the required proportions of the two components (for each grout, they are given on the package) and make the volume of the composition, which is guaranteed to be used within an hour. New portions of the mixture are prepared as needed. Pigment additives can be added to the base by mixing, or you can buy a product that is already dyed in the desired color.

Surface preparation

From the tile surface remove dirt, dried particles of debris, if possible, vacuum. Then it is necessary let the tiles dry... If it is light, you need to advance darkening test when interacting with grout.

Grouting

After 40 minutes, you can spray the seams with water from a spray bottle and smoothen their finger.

After working with floor tiles, it is not recommended to walk on it for two days, since some of the grout brands are characterized by prolonged drying (up to 4 days).

Cleaning the tiles

Popular manufacturers

Another Italian product - Kerapoxy from Mapei... These grouts have almost no roughness characteristic of most products of this type and are very resistant to acids and reagents. But the color range is not as wide as that of the previous company - only 26 colors.

Among Russian manufacturers can be noted brands "Foundations", "Fugue" and "Diamond"... The latest brand is strictly intended for use in the bathroom and toilet. Available in 46 shades. Grout "Osnovit" is distinguished by high plasticity and resistance to temperature changes in a wide range, withstanding values from -50 to +75 degrees. It is not contaminated with mold and mildew. But the brand has a small range of colors - only 29 tones.