Plywood and OSB are quite suitable materials for rough or fine flooring. They choose between them, taking into account the operating conditions in the room, the nature of the base and flooring, the level of safety and cost.

- Description of materials

- Plywood

- OSB

- Comparative characteristics

- Strength

- Environmental friendliness

- Ease of use

- Water resistance

- Fire hazard

- Thermal conductivity and sound absorption

- Dimensions and shape, weight

- Appearance

- The cost

- What to consider when choosing

- Features of the installation of materials

- What is better to put under linoleum, laminate

- Practical advice

Description of materials

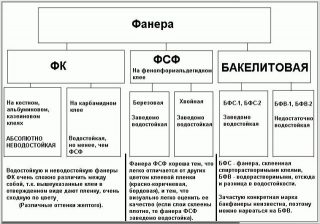

Plywood

Slabs are made from pine and birch. Often, the outer layers of veneer are made of more expensive and beautiful wood to give the material an attractive look. The Chinese version is more often made from poplar.

The characteristics of the material depend on the adhesive used. Albumincasein water-soluble glue is the safest, provides a strong adhesion of the sheets. However, it is not resistant to moisture, so it cannot be used for a substrate in a kitchen or bathroom. Wood impregnated bakelite compounds, absolutely water resistant. This material can even be used to decorate swimming pools.

OSB

OSB of 4 types is produced. 2 options are designed for operation in dry conditions, OSB-3 can be used for laying floors in wet rooms, and OSB-4 withstands high external humidity and can be used as a substrate in open areas and verandas.

The water resistance of the material is ensured only by special impregnations. Itself the structure is rather porous... This provides good thermal insulation properties, but makes the material sensitive to changes in temperature and humidity at the same time.

Comparative characteristics

The properties of construction plywood and OSB are quite different. This must be taken into account when choosing a material for the substrate.

Strength

This indicator depends on the density of the material and the strength of the bond... Average density of plywood ranges from 550 to 750 kg / m³... However, more porous sheets are produced - with a density of 300 kg / m³ and more dense - 1000 kg / m³. Average values are quite enough for the substrate.

The tensile strength under load depends on the type of plywood. So the indicators of FBS or FBV are 2 times higher than those of solid wood, and FSF or FK are 3 times inferior in strength.

OSB strength exceeds the strength of conventional plywood sheet and reaches values from 2500 to 4800 MPa - along the longitudinal axis. Bakelite plywood will be stronger. However, both materials can cope with the role of a substrate or even a finishing flooring. The bending strength of plywood is 2–4 times higher.

Environmental friendliness

Sustainability is determined by the binder. The most environmentally friendly version of plywood - FBA brand... Albumincasein water-soluble glue is used to glue it. However, for work, more harmful options based on formaldehyde and melamine resins are much more often used. In this case, it is necessary to take into account the emission class - no more than E1.

The choice of binders in the production of OSB is much less. However, when choosing, you also need to pay attention to the emission class.

Ease of use

OSB and plywood can be sawed and cut in any direction... It is allowed to use both a hand tool and an electric one. Plywood can be bent. The bending ability of OSB is extremely limited.

Both materials hold fasteners well.

Water resistance

- FCM and FSF - in the manufacture of formaldehyde or melamine resins are used. They provide medium resistance to moisture - the material does not swell in a dry living room. It is allowed to use it in the bathroom and kitchen if the premises are equipped with an extractor hood. However, when leaking or flooding, such material swells, then dries, but loses strength and evenness.

- BS - waterproof special plywood bonded with bakelite glue. Does not rot, does not grow moldy, withstands direct contact with water.

- FB - material impregnated with bakelite glue. Used in tropical conditions and even underwater. Very expensive.

- OSB-1 - swells in a humid room, increasing by 25%;

- OSB-2 - increases by 20%, it is allowed to use only in a dry room;

- OSB-3 - absorbs no more than 15%;

- OSB-4 - swells up to 12%, is more often used for external structures.

In dwellings, high moisture resistance is rarely required. Sometimes this problem is solved by a simpler method - they use film faced plywood.

Fire hazard

Both materials are highly flammable... Wood cuts, shavings, polymer resins burn well and support combustion. You can make slabs less combustible by using special impregnations at the manufacturing stage. Such material is classified as special and is more expensive.

Thermal conductivity and sound absorption

Average thermal conductivity coefficient of OSB is 0.12 W / m * K... The same indicator for plywood it is 0.18 W / m * K... The parameter depends on the density: the higher it is, the worse the thermal insulation qualities.

Sound insulation is approximately the same and is also determined by density.In fact, the sheet backing is not made to protect against structure-borne noise, but in order to fix the finishing boards in the correct position. At the same time, unnecessary sounds disappear.

Dimensions and shape, weight

The dimensions of plywood are determined by its density and purpose. FCs are more often produced in the form of squares with a side length of 1525 mm and a thickness of 3 to 22 mm. The dimensions of the moisture-resistant FSF are different: the width is 1220, 1250, 1525 mm and the length is 1525, 2440 and 2500 mm with a thickness of 6 to 35 mm.

OSB sizes are more standardized. Most often these are sheets of 2440 * 1220 and 2500 * 1250 mm with a thickness of 9 to 22 mm.

The weight of the slabs depends on the density. In general, with the same thickness and close density, the weight of plywood and OSB will be almost the same. The difference is insignificant for calculations.

Appearance

Plywood is much more attractive. Its front side is a cut of a tree trunk. The OSB surface is formed from long shavings. The texture is quite unusual, but much inferior to the woody pattern.

The cost

The difference in production technology causes the difference in price. Plywood is made from veneer, while OSB is made from waste - shavings. therefore the cost of OSB is always much lower. The difference is all the more significant the more waterproof or durable types of plywood and OSB are compared. FC costs 1.2 times more than OSB, and FSF - 1.6-2 times.

What to consider when choosing

The main criterion for choosing between two substrates is appointment.

- To the nursery the room is always chosen plywood, since this material is much safer than analogues. It is preferable to buy FC.

- In the kitchen, bathroom, on the balcony you need moisture-resistant varieties of OSB or plywood.

- For bedroom they prefer OSB with a low emission class, since the material absorbs structural noise slightly better than plywood.

- Indoors with high traffic - plywood is needed, since its strength and wear resistance are higher at the same thickness.

Other parameters are also taken into account: the height of the room, the general arrangement of the floor, the presence of a "warm floor" system.

Features of the installation of materials

You can lay the substrate on any base, but at the same time take into account the peculiarities of each.

On a concrete screed - sheets with a thickness of at least 8 mm are required. If thermal insulation is not required, the material can be glued to the base, and the fasteners can be duplicated with self-tapping screws.

When laying on lags sheets should be thicker - 20–22 mm. Often it is required to mount additional logs to reduce the deflection of plywood or OSB. When laying, the sheets are screwed to the logs with self-tapping screws in increments of at least 10-15 cm.

On a wooden floor plywood sheets are laid end-to-end, but a gap of 1 cm is left between the material and the wall. They are fixed to the tree with self-tapping screws in increments of at least 15 cm. At a shorter distance, the plywood will lead. If the substrate is prepared for linoleum or other soft coating, the joints are sealed with a sealant.

OSB is laid differently. Plates with a thickness of 12 mm are staggered, so that the joints do not coincide. Fastened with self-tapping screws to the floor in 30 cm increments.

When installing, it is worth remembering that plywood is a more rigid base than OSB.

What is better to put under linoleum, laminate

The choice between OSB and plywood is carried out taking into account the nature of the final flooring. The stiffer it is, the more solid the foundation is required for it.

- Parquet requires perfect evenness and hardness of the substrate. Only plywood is allowed.

- Planks - due to their size and thickness, they form a self-supporting structure. Here, the substrate plays the role of a sound insulator, so OSB is preferable.

- Laminate - a sufficiently elastic and durable material, but sensitive to displacements and changes in moisture. It is preferable to put plywood under it.

- Linoleum - soft flooring. Both OSB and plywood are suitable for him.

Both materials can be used when installing a "warm floor".

Practical advice

When arranging floors, such nuances are also taken into account.

- In rooms with high humidity it is better to use plywood. After pouring and drying, it restores its properties to a greater extent. OSB deteriorates faster.

- In misconfigured rooms it is better to work with OSB.In addition to standard sizes, sheets are available in a wide variety of sizes.

- Plywood fits tighter on the base... Therefore, when installing on a concrete floor, it is worth taking care of additional sound insulation.

Better board.