Aerated concrete is a popular building material. On the one hand, it has the strength and hardness typical of concrete, on the other hand, it weighs less and retains heat better. However, these qualities depend on the number of pores - the density of the material.

Application of aerated concrete grade D300

When making foam concrete, add to the initial mixture gasifier. It reacts with one of the components of the mixture. As a result of the reaction, a large amount of hydrogen is released. Gas bubbles penetrate the mass of concrete, but cannot escape and form a material in the body many tiny pores.

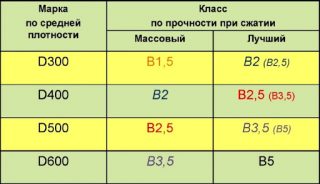

Depends on the number of pores density stone: the more there are, the lower it is. The resistance to loads depends on the density. The material is available in different porosities, respectively, of different densities. This determines its application.

Aerated concrete D300 belongs to the category structural and thermal insulation materials. Blocks can be taken for the construction of load-bearing walls and for insulation.

Aerated concrete D300 apply in the following cases:

- when constructing multi-storey buildings with a wall thickness of at least 30 cm and mandatory cladding;

- in the construction of low-rise houses for permanent residence;

- in the construction of country houses for seasonal residence, outbuildings and temporary structures.

According to GOST, the wall in one block has sufficient bearing capacity. In fact, you cannot even build a 2-storey house without first calculating all possible loads.

Description of physical and technical characteristics

Gas block 300 has density of 300 kg / m³. This quality determines its other physical characteristics.

- Dimensions (edit) building blocks are standardized: width - 300 mm, height - 250 mm, length - 625 mm. Such a large size of one piece with a high dimensional accuracy can significantly speed up the installation.

- Weight products - 17-21 kg. For other sizes, there may be more.

- Thermal conductivity - 0.88 W / m * C. This is the maximum indicator for structural and thermal insulation materials.

- Strength - 2 MPa. Under greater load, the stone deforms.

- Frost resistance - 100 complete cycles.

- Fire safety class - non-combustible materials.

Aerated concrete, due to preliminary steaming in an autoclave, does not shrink.

Popularity of the material

- Heat capacity foam concrete is noticeably higher than usual.Aerated block walls can be thinner, which reduces construction costs.

- Due to the same quality, the walls of cottages and summer cottages are for living only in summer no need to insulate.

- A rock weighs little... The foundation for it is made lighter and cheaper.

- To lay down large blocks easier. This reduces construction time and costs.

The only emerging expense item is finishing. The foam block is hygroscopic, so the facade needs to be plastered or revetted.

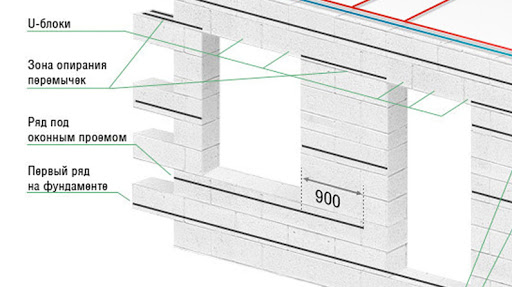

Styling features

Aerated concrete construction D300 is carried out taking into account the characteristics of the material. Recommendations are as follows:

- gas block masonry is not too strong, therefore foundation the house should not be massive, but hard, reinforced concrete is best;

- foundation carefully waterproof roofing material, mastic;

- blocks of 1 row are placed on cement-sand mortar, since this mixture can level the surface of the foundation;

- when laying 1 row, the position of each stone is checked and adjusted;

- the rest of the rows lay on glue, which allows you to reduce the thickness of the seam to 3 mm;

- glue needs to be taken qualitative, recommended by the manufacturer, as the cheap one crumbles over time;

- dressing size with a D300 gas block height of 250 mm, it is at least 40% of the height;

- prohibited use when laying material trim less than 50 mm long;

- it is forbidden to pair load-bearing walls with interior partitions both by dressing and by scraps of reinforcement;

- exterior walls, like the internal ones, they are rigidly mated to each other - due to the binding of the brick;

- in windowsill areas and the doorway must be reinforced;

- under the overlap, you need to equip armap-belt.

The reinforcing belt must be continuous - lie not only under the Mauerlat, but also along the gables.

Main manufacturers

Aerated concrete 300 is produced by a number of well-known companies:

- Xella - produces autoclaved aerated concrete of various densities;

- Aeroc - manufactures gas blocks on a high-tech line from Wehrhahn Smart;

- LSR is a Russian manufacturer that produces both heat-insulating and structural aerated concrete;

- Stoklite is a Russian company offering porous blocks with increased resistance to heat transfer.