Aerated concrete is one of the most popular building materials. Depending on the degree of voidness, structural and heat-insulating material options are distinguished. Aerated concrete D600 is the most durable and reliable grade of aerated concrete.

Description of aerated concrete blocks D600

The porous version differs from the usual one by the presence of small voids... They appear due to a special manufacturing technology. Bubbles filled with gas are evenly distributed over the concrete mass. At the same time, the material increases in size, its density decreases, and its weight decreases.

Aerated concrete loses its high bearing capacity, but gains others: lightness, heat-insulating and sound-insulating properties.

In private construction aerated concrete blocks D600 are used very actively... The stone is produced in large sizes, but at the same time it has perfectly accurate dimensions and perfectly defined contours... These blocks are easy to install due to their low weight, and the assembly of the wall takes much less time.

Another important consequence of dimensional accuracy is extremely tight docking... The thickness of the seam between the blocks is 1–3 mm, so the blocks can be placed not on the mortar, but on the glue. Such a wall will retain heat much better due to the lack of wide gaps between the stones.

Advantages and disadvantages, scope

The structural feature of the D600 gas silicate blocks provides the material with many advantages. Moreover, it makes the material for private construction the most convenient and in demand. After all, usually the home craftsman does not have much experience in laying bricks, but for the construction of walls from highly qualified blocks is not necessary.

Aerated concrete easily absorbs moisture, but also easily releases it. The disadvantage of this quality is in areas where there are frequent prolonged rains.

What it consists of, the declared properties

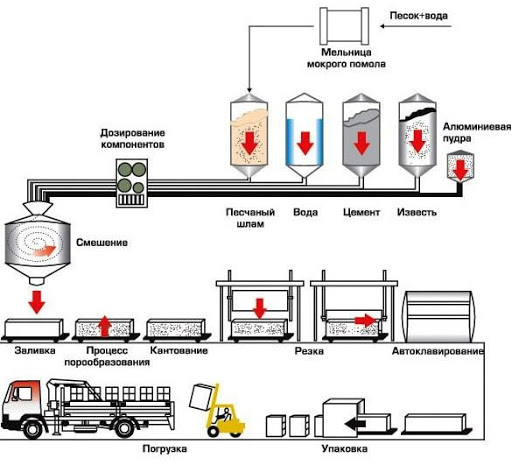

Aerated concrete D600 owes its qualities manufacturing method... Into the initial mixture of Portland cement, quartz sand and water add lime... This component plays the role of an active ingredient. Then the composition is introduced gasifier - most often aluminum powder. It actively interacts with lime to form hydrogen. Gas cannot escape from the mass of concrete. It forms many bubbles that spread throughout the entire thickness of the material, noticeably increasing in volume - this is how swelling occurs.

After solidification the mass is cut into blocks and processed in an autoclave at a temperature of + 200 ° C and a pressure of 10–12 atm. In this case, the material gains the maximum possible density, since additional chemical reactions occur under these conditions.

The degree of porosity is determined by the ratio of the components. Exactly all other qualities of gas silicate are associated with the density index.

Physical and technical characteristics

- Density - 600 kg / cubic meter.

- Strength - withstands a bearing load of up to 55 kg per cubic meter. cm.

- The thermal conductivity coefficient is 0.14 W / (b * C).

- Noise insulation index - with a thickness of 10 mm is 36 dB, with a width of 300 - 55 dB.

- Water absorption - from 5% for hydrophobized material to 32% for normal material.

- Thermal and sound insulation properties

Aerated concrete 600 refers to construction materials, for which the determining quality is strength, and not the ability to retain heat. Nevertheless, the indicator of D600 blocks is 0.141 W / (m * C), and the thermal conductivity of structural concrete with a density of 1000 kg per cubic meter. m is only 0.34 W / (m * C).

The degree of porosity determines the ability to muffle sounds. A wall made of D600 material with a thickness of 10 cm extinguishes all sounds quieter than 40 dB. If the noise is stronger, for example, 50 dB, a sound with a strength of 10 dB will be heard in the room.

Features of the use of aerated concrete blocks D600 in construction

The characteristics of aerated concrete D600 determine its application:

- for the construction of southern buildings and outbuildings up to 5 floors;

- for filling reinforced concrete frames of any height - this is how external walls are formed;

- for interior partitions, as the material absorbs sound very well.

The material of construction does not retain heat well enough. Therefore, the walls of the D600 have to be insulated if the house is not being built in the very south.

Main manufacturers

The D600 gas block is produced by quite a few enterprises. In Russia, the most famous the following companies:

- XELLA - a German plant producing wall, partition and tongue-and-groove blocks. The products are distinguished by the best set of thermophysical and strength properties.

- Aeroc - the brand is produced by a plant in St. Petersburg using Ytong technology. The company offers autoclaved gas silicate with a density of 300 kg / cu. m up to 600 kg / cu. m.

- Bonolit - entered the market in 2006. The company produces gas blocks, both heat-insulating and structural. Bonolit products are distinguished by high mechanical and adhesive properties.

- Poritep - offers gas silicate and aerated concrete blocks. A distinctive feature is increased strength at the same density. This became possible thanks to the additive - aluminosilicate granules filled with nitrogen.