Laminate is one of the most popular flooring materials. Its main drawback from an operational point of view is the fear of water. When exposed to its regular or prolonged action, it deforms and acquires defects. In order for the coating to serve for a long time, it is necessary to observe the technology of its laying and to close up the joints with high quality. For these purposes, a laminate sealant is purchased.

Why use laminate sealant

Like other wood based materials, laminate does not tolerate water well... Moderate ingestion of it during wet cleaning will not harm the coating. If the liquid penetrates between the planks and soaks the base, the products are irretrievably deformed, not returning to their original shape after drying. The appearance of such a floor can be improved only by dismantling the damaged planks and installing new ones in their place.

Composition and properties

Joint compounds are most often produced on polyurethane, silicone or acrylic base... Various kinds of additives are introduced into them - for coloring, plasticization and other purposes.

Most often gThe sealants contain:

- antiseptic and fungicidal ingredients that protect the material from damage by fungus and mold colonies;

- mechanical additives (eg chalk);

- viscosity-lowering additives;

- coloring additives.

It is not recommended to buy a gray sealant in the hope of turning it into a colored one at home. It is better to immediately acquire a product of the required shade, since these mixtures do not lend themselves to self-coloring.

When choosing a sealant for laminate joints, it is recommended to pay attention to the following characteristics:

- the most important thing - ability to seal joints between panels and other gaps, reliably protecting them from moisture penetration;

- product should not glue too tightly panels with each other, the possibility of their dismantling must be preserved;

- he should be safe for residents (including pets);

- his surplus should be easy to remove after application;

- he should be elastic, but at the same time durable and resistant to environmental influences, tolerate moisture and temperature fluctuations well;

- means shouldn't stand out too much on the surface of the coating;

- also important ease of self-assembly: it is good if the work does not require complex expensive tools (most often a foam gun is used to install the sealant).

Plus will be noise insulation qualities product. It's good if the remedy dries quickly, but at the same time, in the first minutes after application, it is easy to remove excess.

Varieties of sealants

- Silicone refers to organosilicon substances and is widely used in various industries. Silicone products for sealing joints have high elasticity, strength, firmly adhere to the surface. They are safe for humans and animals, easy to use, tolerate temperature changes well. When working with them, no greasy marks remain on the laminate. Such products are used to seal gaps and seams, to protect the material from the action of water.

- Acrylic refers to synthetic polymers... Sealing compounds based on it are used to protect against moisture and to mask minor flaws in the floor surface. The sealed seams retain their fresh appearance for a long time and do not turn yellowish over time. Due to the absence of polyester resins in the composition, the products are safe for family members and pets.

Terms of use

- The end parts of the panels into which the composition will be applied must clean from litter and dirt. If necessary, you can use a vacuum cleaner.

- The composition is applied inside the groove or on the top of the tongue... When working with funds based on polyurethane, the second option is practicedt. They quickly set, so if the panel requires cutting, you must first perform this operation, then check that the lamellas fit well and connect, and only then work with the composition. Mixes on acrylic or silicone can be applied in either of these two ways... Many people say that it is more convenient to squeeze the mixture into the groove. In this case, after applying the sealant, the panel immediately (without waiting for it to harden) is inserted into the groove of the previous part with its end face and snapped into place. The sealant is spread over the top and bottom sides of the groove recess. This can be done with a rubber trowel, which is used to process the seams in ceramic tiles. The ends of the panels should also be smeared with the mixture. You can apply it with your finger, but it is difficult to wash your hands after that.

- After that you need remove excess sealant... This is easiest to do after a short exposure period (15-20 minutes). But it is important not to make it too long, otherwise the sealant can only be removed with a special solution.Traces that do not come out quickly can be removed with an eraser. The use of abrasive brushes is prohibited - this can create damage to the surface of the laminate that cannot be repaired.

When repairing a floor need first disassemble the old laminate... If the end parts of the panels have traces of old sealant, his remove with a rubber spatula. If you cannot remove them purely mechanically, you can use a solvent. In this case, you need to work carefully in order to maintain the integrity of the lock fasteners. Thereafter sealing with fresh sealant according to the algorithm described above.

Popular manufacturers

Now on the market you can find a wide range of sealants of domestic and foreign companies. Among them, you can choose a product that is suitable in terms of properties and method of application. The following products are in demand:

- German company product Click Guard for laminate and parquet flooring, produced in tubes with a nozzle (one package is enough for 8 sq.m. area) and does not require special tools for installation. It is necessary to remove excess composition 15 minutes after application. The tool also has a minus - it is quite expensive.

- Soudal - a colored product based on acrylic. Good adhesion, also suitable for repairing scratches. Excess product can be removed with a damp cloth. A special gun is needed to work with the sealant.

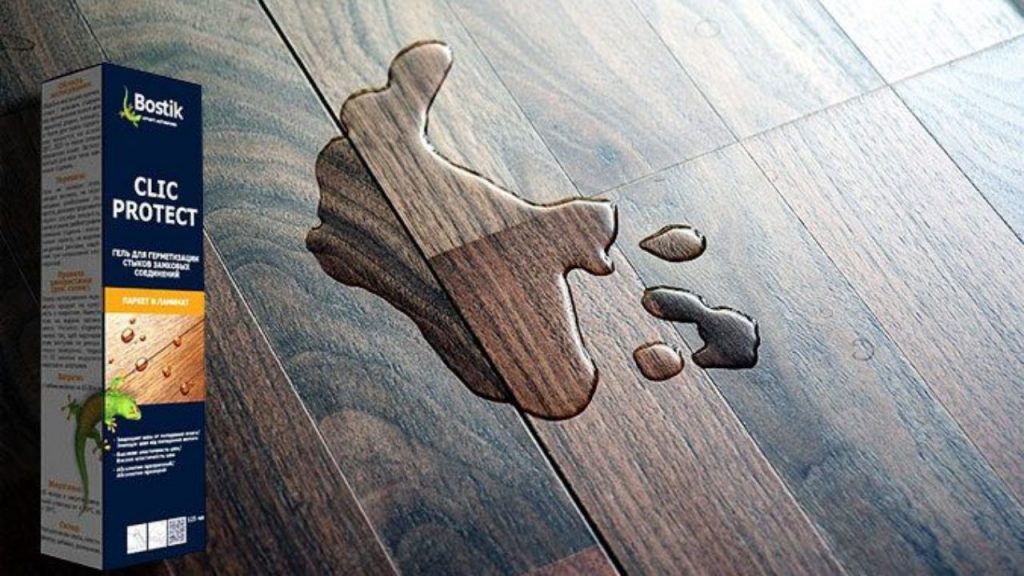

- Click Protect - a colorless product made in Sweden, very economical (packaging is enough for 15 square meters), but hardening for a rather long time (half an hour).

The product can be packed in a plastic jar or in a tube (standard, made of aluminum, or designed for installation in a gun). The container comes with a nozzle with a long tip.

Before work, it is advisable to warm up the product a little (up to 25-30 degrees) - then it becomes more elastic and easier to apply. But you cannot overdo it, otherwise the container may explode. After heating, the tip is cut off the nozzle. As the tool is spent, the radius of the cut part can be made larger.