Sealants represent a large group of materials used for sealing joints during the installation of structures, repair work and interior decoration. Sealant for plastic windows allows you to quickly and efficiently fill the gaps between the frame and the slopes, remove gaps and cracks on the window block.

Description of sealants for plastic windows

Types of sealants:

- curablewhich obtain a stable form by solvent evaporation or polymerization;

- not curable - putties that do not change their properties over time, remain soft.

There are pastes that can be used at sub-zero temperatures; in frost they do not change their original characteristics.

All varieties adhere well to metal, wood, stone, concrete, porous blocks.

Appointment

Sealing compounds are produced in accordance with the standards of GOST, TU (technical conditions). The requirements for the correct use of materials are spelled out in the technical regulations for sealing materials.

Sealing pastes used for work:

- sealing joints on aluminum, plastic, wooden windows, when installing window sills;

- sealing gaps between slopes and frames of plastic doors and products from other materials;

- sealing small cracks on window slopes made of plasterboard, PVC strips.

Waterproofing is used as a top layer of foam at the junction of window frames and blocks on the balcony to the ends of the walls in the openings.

Properties and qualities

Requirements for sealing pastes:

- the material should not collapse during a long time of operation outside the opening;

- should not be destroyed under the influence of blows;

- the composition must repeat the grooves, stretch and contract with the thermal expansion of the frames and walls of the building.

High-quality sealants are not blown by the wind, so foreign odors do not get inside the room, the elastic seam dampens sound waves.

Varieties of compositions

Window sealant is produced by:

- in plastic tubesthat are inserted into the pistol;

- in soft packs by the type of sausages, also require the use of a special type of pistols;

- two-component applied with a self-priming gun or spatula.

Sealing pastes are classified according to their chemical composition.

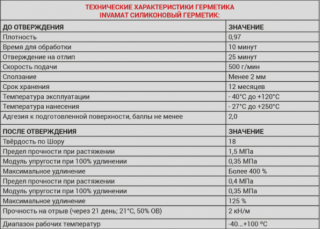

Silicone

Silicone mixture contains Components:

- substances that increase the compressive strength, tensile strength;

- plasticizer;

- the fluidity is determined by the vulcanizer;

- primer to improve adhesion;

- dye.

Silicone does not allow moisture to pass through, does not absorb it. The layer on the frames does not turn yellow, does not collapse from ultraviolet radiation, shrinks when hardened by 2%.

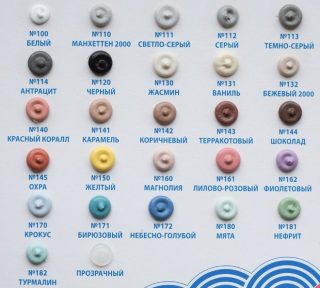

They produce white, transparent, tinted pastes. One-component types are acidic and neutral, the former are cheaper and of low quality.

Acrylic

Sealant for window seams contains:

- modifiers for flexibility and plasticity;

- foam absorbers to reduce volume and swelling;

- thickeners to increase density;

- fillers in the form of chalk, lime;

- antiseptics to increase biological resistance.

After hardening, plasticity remains, so the sealant can easily withstand vibrations when opening and closing window sashes. After squeezing or stretching, the seam tends to return to its previous position.

Acrylic compounds are moisture resistant, non moisture resistant, frost resistant. The first look works well on the inside of a bathroom frame. Frost-resistant are used for external seams.

Polyurethane

The composition is used Components:

- rubber particles;

- fillers (quartz, lime flour);

- expanders;

- antiseptics against fungus and other harmful microorganisms;

- mineral-based oils;

- dyes.

Withstands temperatures of -55 ° - + 80 ° C, keeping its original qualities. The polyurethane compound does not react to moisture, aggressive atmospheric chemistry. Mold does not develop on the surface, so the seams always have an attractive light appearance without blackness.

Alkyd

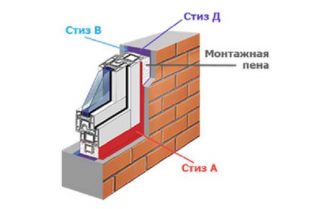

Popular varieties have marking:

- STIZ A - for outdoor use only;

- STIZ B - seals internal connections;

- STIZ D - a new version, protects the frame from wall moisture, is applied before the installation of a window or door block.

Such compositions are packed in small buckets; spatulas are used for lining. When laid on the ends of the walls, it does not spread, quickly sets, adheres well to wood, stone.

Butyl

Isolator functions:

- creates a barrier for moisture penetration inside the glass unit, protects against fogging inside, settling of condensate droplets;

- connects the edges of the glasses with one or more spacers.

Produced in two-component, mixed before use.The sealant is black, but after assembly the window is not visible.

The composition is applied along the contour of the glass unit with a butyl extruder, avoiding breaks and unfilled areas.

The composition adheres perfectly to glass and metal, withstands the action of ultraviolet radiation, after hardening does not emit harmful components. The sealant is produced only in black, but after assembly of the window it is not visible.

Which one to choose for interior and exterior work

The street seam is exposed to negative influences, therefore, it is chosen taking into account its resistance to temperature differences, frost, rain, snow and wind. For this purpose, silicone and polyurethane compounds are better suited - they will ideally cope with the task at hand. Alkyd STIZ A of white color is practically invisible from the street side, but it differs in moisture resistance, hardness and elasticity.

Recommendations for use

Application tips:

- if a layer of previously applied foam is covered with a paste, it is cut off so as to create a small depression for applying the sealant;

- use a gun if the product is in tubes, or use a small rubber, plastic spatula;

- the tip of the tube is positioned at 45 ° so as not to obstruct the view.

If they work with a spatula, it is lubricated with soapy water so that the composition sticks less. So you can treat your hands before applying.

Clearances between slopes

Working rules:

- a construction knife with a retractable blade is used for trimming the edges;

- if the gaps are not wide (up to 1.5 cm), then take a pistol, wide gaps are more convenient to close up with a spatula;

- the edges of the joint are pasted over with masking (paper) tape so that the composition does not stick to adjacent areas;

- the seam is tightly filled with sealant.

Immediately use spatulas of a special shape to create a round or angular surface of the seam. They carefully remove the excess paste. It is better to remove the scotch tape immediately, without waiting for the composition to dry.

Slots in window frames

Be sure to use masking tape, soap solution and foam sponge to remove excess material. It is advisable to degrease the areas where the sealing paste is applied. The trigger of the pistol is pressed smoothly, the correct speed of movement of the tube is selected. This will not create excess thickness, and there will be no unprocessed gaps at the joint.

Usage temperature

The size of the working range for overlaying is usually narrower. After hardening, the material becomes more frost-resistant, withstands high performance.

Recommended temperaturesthat the window sealant withstands:

- acrylic composition - from -20 ° to + 70 ° С;

- silicone - -40 ° - + 150 ° С;

- polyurethane - -55 - + 80 ° C.

Alkyd STIZ A (for outdoor work) is operated at -60 ° - + 80 ° C, and butyl (for double-glazed windows) do not collapse in the range of -55 ° - + 130 ° C.