Insulating building materials are used in the repair and installation of plumbing fixtures, water supply networks, sewer mains. At the joints of the water pipes, between the sink, toilet and the wall, a sealant is used to eliminate water leaks. The protruding drops increase the humidity in the bathroom, and the dampness leads to deterioration of the finishing materials, so leaks must be dealt with.

Description of plumbing sealants

According to a change in state, sealants are:

- solidifying - the solvent evaporates from the mixture during hardening, the mass polymerizes;

- non-drying - the consistency does not change after application, remains plastic.

Plumbing sealant adheres to brick, concrete, stone with high quality, adheres to plastic, wood, drywall. There are heat-resistant varieties that are used to process joints of metal and plastic (PVC) hot water pipes. For unheated bathrooms, frost-resistant varieties are used.

Composition requirements

The main condition is inability to absorb moisture... The sealing compound should also not be destroyed by vibration. Pipes can shake if the water flow is under pressure.

Qualitative the composition should provide:

- insulation of the seam from moisture;

- sealing of existing cracks, joints;

- filling of cavities of cracks and other defects on a flat surface.

Has the meaning shrinkage degree, since the mass should not decrease in thickness and width. In the bathroom, sealants should serve for a long time, not deteriorate from dampness, and maintain quality throughout the operation.

IN composition of sealing pastes introduce components:

- defoamers to reduce foaming;

- plasticizers for resistance to vibration and deformation;

- thickeners;

- fillers (chalk, lime, other substances);

- antiseptics, biostimulants.

Characteristics

The sealants have good adhesion. Acrylic withstand -25 ° - + 80 ° C, silicone - -50 ° - + 150 ° C. Heat-resistant varieties retain their qualities when + 250 ° C.

Properties of sealants:

- Elasticity manifests itself in the fact that the pastes do not crack when the surfaces to be joined are shifted by up to 7.6%.

- All formulations grabbed (film appears) in 10 - 20 minutes, for complete solidification required from 8 hours to a day.

- Compositions do not deteriorate from ultraviolet radiationdo not change color.

- On a surface microorganisms do not develop, does not appear black and mildew.

For external use at sewerage joints, as well as for sealing radiator joints and heating pipe joints in the bathroom, special compounds are needed.

Scope of application

The main areas of application of sealants in the bathroom:

- inlets for pipes in walls, sewer outlets in floor slabs;

- butting points for connecting fittings to pipes;

- cracks when installing plastic on the ceiling and walls, holes around spotlights;

- gaps between the wall and the ceiling or floor plinth;

- the gaps between the sink, bathtub and wall surface;

- gaps when leading the ventilation pipe into the wall;

- gaps in the coating when installing a warm floor.

After hardening, a seam is obtained, the shape of which is given with a special spatula.

Varieties of sealants

Sealants are similar in basic qualities, but differ in composition, which affects some indicators. For the bathroom, formulations are used based on acrylic and silicone.

Differences between sealants:

- By moisture resistance... Silicone compounds tolerate moisture well, while not deteriorating from direct jets. Acrylic pastes are less waterproof.

- Perception of loads, susceptibility to deformation. Silicone formulations are more flexible.

- Acidity. Acrylic types are classified as neutral, and acidic types are found among silicone types. The latter cannot be used on iron or foam surfaces.

Any paint rolls down on the surface of the silicone sealant, acrylic seams are decorated with various compounds.

Criterias of choice

The sealing gasket is chosen taking into account suitability in a certain place... The material of pipes and other contacting surfaces matters. On the packaging, the manufacturer provides this information, so you can choose a quick-drying seal for plastic or metal pipes.

Factors are taken into account:

- resistance to moisture, action of direct water jets;

- duration of use;

- flexibility and inability to deform;

- surface temperature, system pressure;

- cost with a large amount of processing.

Preparation before applying sealant

Preparation includes actions:

- cleaning the joint from dust, debris, drying, degreasing with a solvent;

- the edges of smooth surfaces (glass, tiles) are sanded with emery to increase adhesion;

- along the seam, masking paper tape is glued on both sides, which is removed after the strip is formed.

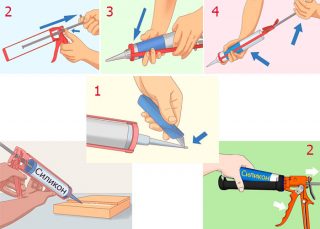

The sealant is inserted into the gun, the protective cap is removed, and the trigger is pulled several times so that the mass enters the tube. Stop the solution supply by loosening the fixing plate on the gun. If you do not do this, the sealant will continue to squeeze out of the tip.

Terms of use

The nose of the tube is placed to the surface at 45 °, so that it can be conveniently applied and not obstructed the view. The gap is filled to the full width and depth, since the sealing materials do not expand during polymerization.

Recommended application parameters:

- depth - 2 - 12 mm;

- width - 6 - 30 mm.

Large gaps are applied several times.After applying the first layer, they are waiting for drying, then the treatment is repeated a second and third time until filling. To shape the seam, there are 10 - 15 minutes after application, then a film forms on the sealant.

On the surfaces of plastic panels, lining, there are cracks, chips, which are treated with a silicone composition of a suitable color or acrylic is used with subsequent painting. The non-shrinking strip resists moisture, the action of household chemicals.

For cold water

Plumbing is often made of plastic pipes, they are joined together by welding or threaded fittings. In the second case, it is imperative to use a sealant to prevent fluid leakage. You can take acrylic mixes, which effectively insulate cold water pipes.

For hot water

In this case, more often use silicone varieties. It is taken into account that not all sealants belong to the heat-resistant category, therefore they are chosen according to the manufacturer's information on the packaging.

The heated elements also include sewer pipes, which are connected to the socket through rubber gaskets. When draining hot water, the joints can depressurize, so they are also sealed with silicone.

Under pressure

Sealants are especially durable based on sodium silicates. After hardening, such pastes have a high strength. They are used when joining water pipes and other pipes operating under pressure. If the pipeline supplies hot water, for example, from the boiler to the point of analysis, such compositions will additionally withstand high temperatures.

Popular manufacturers

Famous brandsin the first lines of the rating:

- Soudal produces flame retardant Gasket Seal and Fire Silicon... The second gray grade is used to seal hot pipes and thermal sections of a warm floor. Gasket Seal remains elastic after hardening.

- Loktite make sealants based on silicone and silicate, there are types for cold and hot pipelines, as well as for isolating circuits under pressure.

- Hilti manufactures products of high quality and affordable cost. The sealant adheres well to smooth materials.

- Makroflex does not collapse up to + 260 ° С, one-component and two-component mixtures resistant to temperature fluctuations, flexible. Not applicable for lead and copper pipes.

- Penosil - quick-drying compound for joints of hot elements, boiler outlets, ventilation ducts, as it withstands temperature up to + 1200 ° С.

- Moment. The paste works great on different surfaces, the catalog contains acrylic and silicone.

- Krass used for sealing joints of hot pipes. The strip is durable without shrinkage.

Products of well-known brands do not crumble at high temperatures, since trusted manufacturers guarantee decent quality.