The problem of gaps in bathrooms between plumbing fixtures and the wall is common. The problem is solved by a waterproof sealant for the bathroom with antifungal impregnation, which seals the joints, eliminates leaks. There are different types for application in seams, for stickers, intended for painting and without post-processing.

The need to use sealant in the bathroom

Viscous paste based on oligomers and polymers applied to joints in the bathroom to prevent moisture penetration. The waterproofing layer is produced directly in the joint, where the product hardens. The composition sets due to the evaporation of the thinner or curing of the polymers inside the sealant. There are types that do not harden, they are classified as non-drying preparations.

The need for application caused by the following circumstances:

- there are open cracks on the ceiling at the entrance of PVC panels into the corner;

- there are gaps between the bathroom and the wall with a tiled or plastic coating due to the curvature of the wall or the absence of a right angle;

- at the joints of sewer collectors, you need to make a gasket during assembly;

- when installing a shower cabin, a gap appears between the profile and the wall;

- there is a gap between the toilet bowl and the floor, tulip leg, sink and ceramic tiles on the wall;

- several tiles on the wall have peeled off, you need to glue them exactly in place.

Gaps are inevitable when installing the sink (between its back and the wall).

There are sealants for processing the seams of tiles instead of grouting, for this they use a spatula of a special shape.

What to protect from

Trouble from leaks in the seams:

- When installing a plastic covering of walls or ceilings, moisture penetrates through the cracks into the frame structure, starts inside fungus.

- Water flows into the gap between the bathroom and the wall with each use, the space under the bathroom is difficult to clean, so it develops there dampness, a swampy smell appears.

- Bad smell audible if the joints of the sewer pipes are not sealed.

- Moisture accumulates in unpatched tile joints, they turn black over time, they look ugly, the coating gradually collapses.

High humidity, steam and warm air contribute to the development of harmful microorganisms, mold, which spoils the surface of the walls. In addition, fungi and flower poses a health hazard.

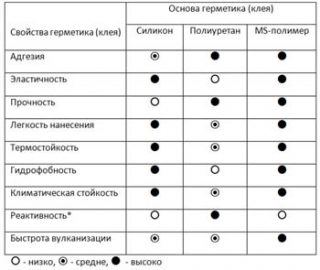

Varieties of sealants and their properties

Moisture resistant plumbing sealants are classified according to their readiness for use in the workplace.

Allocate two categories:

- one-component compounds that can be directly used for sealing joints without prior preparation;

- two-component and multicomponent - in such variants, the agent itself is mixed directly with a hardener and other necessary additives before work.

One-component sealants are divided into types according to their chemical composition, which determines their quality and technical indicators.

For all types characteristic are the properties:

- strength after hardening;

- resistance to deformation under the action of steam, moisture, temperature change;

- good adhesion to any materials on which they are applied;

- shrinkage of varying degrees during setting, reduction in size;

- elasticity, flexibility, inability to crack;

- long term of work in a bathroom.

- acrylic composition;

- waterproof silicone sealant for the bathroom;

- polyurethane sanitary sealant;

- paste with MS polymers.

Each type is intended for use in specific conditions in order to effectively use the composition.

Acrylic

Acrylic bathroom sealant contains additives of various actions:

- modifiers provide plasticity;

- defoamers reduce the volume of foam;

- thickeners give the required density;

- fillers enhance the desired properties;

- antiseptics prevent the development of microorganisms.

After hardening, the substance remains plastic and adapts to vibrations. The product is glued to the surface of wood, stone, concrete, steel, plastic. Paint is applied to acrylic sealants and does not roll up compared to silicone types. After stretching or squeezing, the seam returns to its original state.

- Non-moisture resistant. Used for dry rooms, but not used in the bathroom.

- Moisture resistant. Designed for bathrooms, showers, kitchens with humid air. Adheres well to porous and smooth surfaces.

- Frost resistant. Such funds are applied in country bathrooms if you have to leave for the winter. In the spring, the quality of such a sealant remains unchanged, despite the fact that the house was not heated in frost.

Acrylic pastes have high adhesion to plastics, exhibit chemical neutrality. They are produced in white or with colored pigments. Apply the product width from 0.6 to 5 cm, with an increase in the cross-section of the seam, a sealing cord is used.

Terms of work:

- when calculating the amount of funds, take a conditional seam with a thickness of 6 mm and a width of 10 mm;

- during operation, the temperature of the surfaces forming the seam is in the range of + 4 ° - + 32 ° С, and the temperature of the ambient air is -40 ° - + 120 ° С;

- the hardened composition can be painted in 1 - 1.5 days after application.

The product is used on dry surfaces. In conditions of high humidity, cover the place of application with cellophane.

Silicone

Part silicone sealant includes components:

- strength amplifier;

- plasticizer;

- vulcanizer for fluidity;

- primer for adhesion to surfaces;

- pigment for color.

The cost of the material is higher than acrylic, but the product has improved adhesion... Structural types are used for gluing small parts and tiles.

Other qualities:

- does not allow water to pass through, does not absorb moisture;

- withstands temperature without deformation -50 ° - + 150 ° С;

- ductile, high tensile and tear strength;

- does not deteriorate from ultraviolet radiation.

When dry, the shrinkage is about 2%.Keeps working properties for a long time, does not crack (about 7 years). There are transparent, colorless and colored compounds.

- acidic;

- neutral.

The first type of silicone sealant for the bathroom has pungent vinegar smell and lower cost... Obtained by interaction of hydroxyl groups of polydimethylsiloxane with a vulcanizer (methyltriacetoxylane). In this case, acetic acid is released and a network structure is obtained.

Neutral species are almost odorless, more expensive the first option. Release alcohol and amide types depending on the composition. They are used on metal, polyvinyl chloride without fear of ruining the surface.

Large hard and soft tubes are available for insertion into pistols. Small volumes of silicone are filled into hand-pressure tubes. There are large cans for industrial applications.

Polyurethane

The bathroom sealant is injected into the PU and other components:

- dilators (extenders);

- fillers in the form of quartz flour, crushed chalk;

- antifungal fungicides, antiseptics;

- mineral oils;

- pigments;

- rubber.

The material is used in the temperature range -55 ° - + 80 ° С to maintain the declared characteristics. Polyurethane sealant adhesive does not react to water, slightly aggressive substances from the atmosphere. Microorganisms do not develop on the surface of the seams, therefore such joints never turn black, do not become covered with a layer of mold.

Material properties:

- after hardening, an elastic and even seam is obtained, which withstands mechanical loads and vibrations;

- adheres well to surfaces made of any materials (brick, metal, wood, ceramics, glass);

- if desired, it can be coated on top with a paint and varnish composition;

- flexibility allows joining materials with different coefficients of expansion;

- does not deteriorate from sunlight.

Frost resistance composition allows you to seal the seams between plumbing fixtures in the bathroom even in winter in unheated rooms, when the ambient temperature is down to -10 ° C. The substance in vertical joints will not flow down with a thickness of up to 1 centimeter. When solidified, it almost does not shrink, does not decrease in size in width and height.

Approved for use in residential premises, since after hardening, no no harmful substances are emitted into the atmosphere. Polymerization (setting) occurs under the influence of air. This type of sealant is very economical.

Polyurethane products do not withstand too high temperatures (more than + 120 ° С), them can not be applied to wet surfaces. If the moisture content of the substrate is high, use special primers. To some types of plastics, polyurethane compounds adhere poorly.

With MS polymers

The polymerization is planned so that the mechanical properties remain unchanged, but a stable shape is obtained as a result of the crosslinking of the polymers with silane components.

Organosilicon molecules are attached to the uncovered areas, therefore, the qualities of the base polymer are preserved.

- shrinkage at zero level;

- forms a moisture resistant, reliable, durable, flexible seam;

- does not change qualities in the temperature range -40 ° - + 100 ° С;

- can be applied to wet edges of joints;

- combines the useful qualities of polyurethane and silicone;

- able to extinguish mechanical and sound waves.

Inertness to chemical irritants allows you to store the drug for up to two years (+ 5 ° - + 25 ° C). Conveniently applied to the surface with a gun, easily squeezed out at low air temperatures. MS polymer sealants without smell, their use is safe for health. Colorless, with a color scheme, black compositions are produced.

The fast curing sealant cures at low temperatures. For painting, you do not need to wait for hardening, you can apply the paint "wet" - this will not affect the quality. The product has good adhesion to all materials, does not oxidize metals, does not destroy polyvinyl chloride. Fixation of the two surfaces occurs immediately after application.

Criterias of choice

An important factor is becoming material price, take into account and characteristics:

- area of use, type of work;

- manufacturer of the composition, instructions on the packaging;

- sealant color;

- household or professional product;

- application temperature.

For bathrooms, they take sanitary silicone sealant - it is suitable for sealing plumbing gaps, pipe outlets, updating an old seam that was laid earlier.

Application features:

- wall slots - silicone, polymer, polyurethane;

- sanitary gaps - silicone, polyurethane;

- tile joints - polyurethane, polymer;

- gluing mirrors, decor - polymer, polyurethane;

- gluing fillets, skirting boards - any sealant.

Manufacturers rating

- "Moment"... The brand is a subsidiary of the Henkel corporate group. It is engaged in the production of high quality acrylic, bituminous, polyurethane and silicone compounds.

- Ceresit - also a division of the German corporation Henkel. Manufacturing enterprises are located in 70 countries, goods are imported to 125 countries. A wide range of acrylic and silicone sealants.

- CIKI FIKS - a company from Turkey produces silicone types of sealants. Decent quality is combined with a reasonable price.

- Belinka belles - a Slovenian manufacturer mainly produces paints and varnishes for wood, but there are also silicone sealing materials in the product catalog.

- Krass - the company opened production in Poland, Switzerland, the Netherlands. Products include siliconized formulations, silicone and acrylic products.

Sealant removers

- non-seized pastes made from natural materials (fabrics) remove the sealant white spirit, with acetone, use a nail polish remover or petrol;

- hardened compounds are cleaned off mechanically, for example, emery;

- if the substance does not freeze at all, the mass is cleaned spatula, knife blade.

Non-traditional methods include the ability dichlorvos soften the silicone. Some time after wetting, the substance is removed from the surface.