Sealing the seams is necessary not only when laying the floor or roofing. The joints also need to be insulated in the car. However, for the vehicle, you need to use special compounds - resistant to overheating and vibration. One of these is sealant Victor Reigns.

Trademark information

Branches of the corporation today are located in 33 countries. The brand offers seals, axles, shafts, off-road parts and a wide range of gasket products.

Varieties and properties of sealants

Sealing in cars is required not so much for waterproofing as to create sealing circuits and prevent content leakage. It is for these purposes that formulations from the company "Victor Reigns" have been developed.

Of the compositions based on silicone, the most famous are representatives of 2 lines: Victor Reinz Reinzosil and Victor Reinz Reinzosil-t.

- Victor Reinz Reinzosil Sealant Is the most popular option. It looks like a viscous black substance in 70 ml tubes and in aerosol - in 200 ml cans. It is a neutral fast curing sealant that is excellent for glass, metal and plastic. When solidified, the mixture resembles rubber and retains some elasticity. The composition is not afraid of oil, petroleum products, detergents and technical means. Resistant to temperatures from -50 to + 300 ° C, so it easily tolerates proximity to the engine.

- Victor Reinz Reinzosil-t - intended for application on surfaces in which chips and cracks need to be filled. It looks like a transparent gel. It is not so heat-resistant - it can withstand up to + 200 ° C, but is not afraid of ultraviolet radiation. The material is offered in 70 ml tubes.

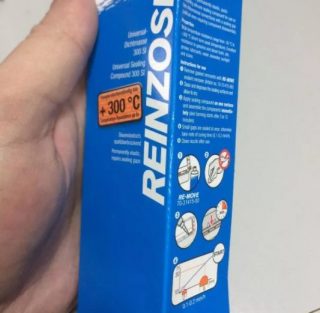

- Victor Reinz Reinzoplast - polyurethane based sealant. Sold in blue 80 ml tube packs or in 300 ml metal cartridges. The product is fluid, retains its viscosity for a long time - this is its main distinguishing characteristic. The composition fills the thinnest cracks and pores - from 0.15 mm in thickness. The option is referred to as non-solidifying - after application and polymerization, it retains very high elasticity throughout the entire service life. Most often used for sealing and sealing threaded connections. Not afraid of oil, technical fluids, high-temperature - stable when heated to + 300 ° C.

In addition to sealants, the company produces other types of seals: gaskets for block heads, flange elements.

Applications

Reinzosil gray sealant is used when insulating gaps engine, housings, switch box, any other metal and plastic parts. Ideal for rough surfaces and can form gaskets. It is also used for additional waterproofing.

Silicone transparent Reinzoplast-t take for gluing parts, for gluing glass and sealing cracks in the windshield, headlights. It dries quickly. The composition is often used as an electrical insulator.

Non-hardening Reinzoplast is applied for sealing threaded and flange connections... It is taken to isolate even very precise precision units, since it does not affect their operation.

Terms of use

The technology for using the composition is described in detail in the instructions. The algorithm is simple.

- Seams and gaps clean from old sealant, dust and dirt. Required degrease, as contact with oil during polymerization reduces the quality of the joint.

- After the surface has dried apply the composition. Use a Victor Reigns sealant gun to ensure accurate application.

- Close the tube cap, the tube is washed with a special agent.

- After 5-15 minutes, the assembly of parts to be sealed.

- Solidification occurs deep into the gap. The setting time is short - 20-30 minutes. The final the strength of the composition is gaining per day at room temperature.