The technology for the production of standard gypsum plasterboard and gypsum boards is different, therefore the moisture-resistant gypsum-fiber sheet has different quality indicators and technical characteristics. Homogeneous panels with bonding fibers have greater strength and density than g / cardboard, therefore, installation on walls is a slightly different principle. The material does not absorb moisture or is fire resistant at the same time.

Description of gypsum fiber sheet

Application area moisture resistant gypsum fiber:

- rooms in residential buildings where moisture, steam vapors are present, but water does not directly get on the walls;

- partitions and wall decoration in unheated utility blocks;

- surfaces in gyms, gymnastic centers, playgrounds where a hard surface is needed;

- walls of industrial premises where there is a fire hazard;

- covering in attics and attics;

- door and window openings after frames installation.

During production, fluff cellulose fibers are introduced into the gypsum mass, which strengthen the material. Cutting waterproof gypsum fiber board (GVLV) is more difficult than standard GKL panels.

Dimensions (edit) gypsum fiber products:

- 1500 x 1000 x 10 mm;

- 2500 x 1200 x 10 mm;

- 1200 x 1200 x 10 mm;

- 1200 x 600 x 10 mm;

- 2500 X 2500 X 12.5 mm.

Moisture resistant gypsum fiber board is produced in large and small-sized elements, but when installing the panel, you still have to cut it to size. Fibrous super sheets do not lend themselves to bending, even to a large radius, and therefore may crack.

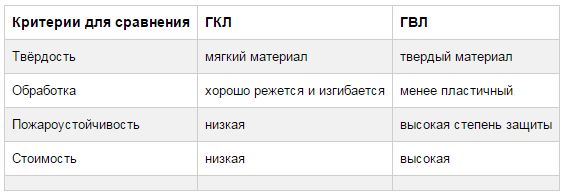

Difference from GCR

- Sheets of g / cardboard are produced with various options for side edges for the convenience of finishing the seams, but panels with straight edges are not made. GVL has products with straight edges and folded edges (FC).

- Profiles under the gypsum board are placed in increments of 60 cm, and the racks under the gypsum plasterboard are placed at a distance of 60.3 cm in order to make the necessary technological gap between the panels.

- In two-layer coatings, plates of both layers are fixed to the profile, and when installing partitions, GVL moisture resistant 1200x600x10mm or 2500x1200x12.5 mm is attached not only to the frame elements, but also to the underlying material.

G / cardboard is not mounted in the form of a leveling rough tier on the floors, since it does not have the required strength, and GVL can withstand household and sports loads.

Technical characteristics of moisture resistant GVL

The products are manufactured for use in dry and wet conditions. The material does not react to chemistry, and is not destroyed by the action of ultraviolet radiation, harmful substances in the air.

Produce products with different markings:

- GVLV - panels are protected from moisture;

- GVL - products are placed in living rooms, where there is no water vapor;

- GVLVO - the material protects against moisture and resists inflammation.

Moisture-resistant gypsum fiber board for walls are mounted in industrial premises where there is a high concentration of steam. So that the panels do not collapse from water, the composition includes hydrophobic additives. As a result, the coating can be installed in bathrooms, kitchens, basements, unheated verandas, corridors. It is allowed to sanitize GVLV, in contrast to drywall, with liquid detergents.

- surface withstands a load of 1250 kg / m³, and due to the high viscosity, nails are driven into the walls, self-tapping screws are screwed in, which are securely held there.

- thermal conductivity at the level of 0.22 - 0.35 W / m allows us to talk about additional protection of premises from the cold;

- material will not miss 34 - 40 dB of street noise, depending on the thickness of the panels;

- frost resistance 15 cycles - this is the number of freezes and thaws that the gypsum fiber material can withstand without losing its original properties.

GVL replaces g / cardboard if strength is required from it, the ability to withstand point loads. It is more expensive than gypsum board, but the increased wear resistance compensates for this disadvantage.

Features of using GVL for walls

The material is fixed in two ways:

- on the frame;

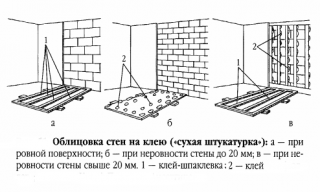

- adhesive method.

The second option is chosen if finishing without insulation is required and the size of the room cannot be reduced. Sheets are glued to a perfectly flat wall from aerated concrete or foam concrete blocks. The GVLV sheet is placed so that there was a technological gap of 5 mm between it and the ceiling, and 10 - 12 mm remained to the floor... Self-tapping screws are screwed at right angles to the plane of the profile to a depth of at least 10 mm.

- choose a flat surface for sawing;

- a marking line is applied on the plate, a rule is used to guide the knife along the line;

- cut 2-3 times along the entire length, evenly introducing the blade into the thickness of the material;

- a wooden lath is placed under the marked line;

- raise the edge of the sheet slightly, break it up, dividing the panel into two parts.

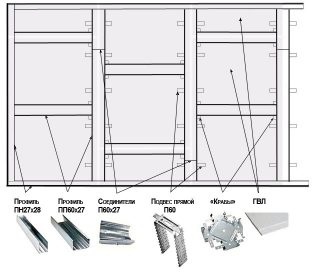

Mounting technology for hot water supply on walls

Profiles apply:

- carrier CD - 60 used for vertically arranged elements, GVL will be installed on them;

- UD - 25 they are placed along the perimeter of the plane, the ends of the CD - 60 profile are introduced into the gap between its shelves;

- suspensions (staples) lengths 90, 120, 180 mm are used for setting profiles, their fastening with self-tapping screws "flea".

Sheets are installed vertically, the edges have with a gap of 3 mm, which is subsequently sealed with moisture-resistant glue. If painting is not needed, the surface can not be putty, but only primed under wallpaper, tiles, cork, etc.