Plasterboard is used for the manufacture of partitions, walls, simple and multi-level ceilings are decorated with it, complex designs of shelves, wall cabinets and other interior elements are made. Depending on the area of application, choose the thickness and size of the gypsum plasterboard. The panels are installed on a frame or mounted directly to the surface with glue.

Description of drywall

The American papermaker began producing "building boards" for various needs back in the 19th century. The material, 15 mm thick, contained a dozen paper layers that held a thin layer of gypsum inside. Augustine Sackett patented the invention, this type of panel became the prototype of the modern type of drywall. A patent for the manufacture of a familiar material, which is now used in construction, was received by an engineer from America Clarence Utsman.

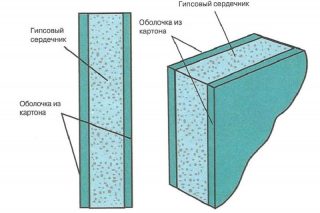

The mass of the leaf contains:

- two-water gypsum - 91.1%;

- cardboard - 5.78%.

The rest is allocated for starch, moisture, modifiers, active substances.

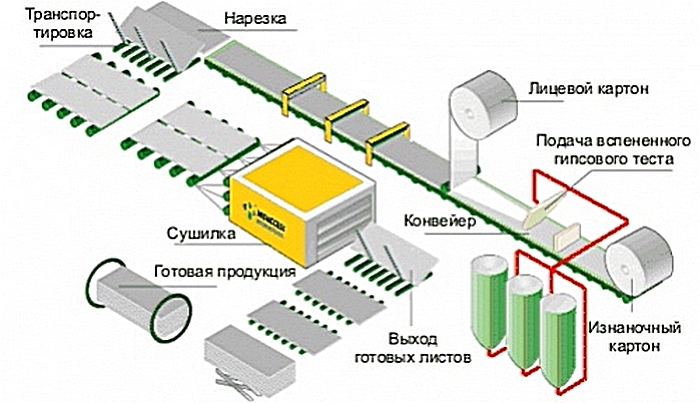

Manufacturing process

Sheets are made on specialized lines, including more than 10 types of machines and other equipment. With the help of automatic production, the product receives the required parameters, in particular, the dimensions and thickness of the drywall are set.

In the production of products, high-quality raw materials and additional ingredients to improve quality:

- steam generating components;

- ingredients to accelerate the setting;

- surface substances to increase the adhesion of gypsum and cardboard;

- water repellents to protect against the action of water in the manufacture of moisture resistant products;

- antifungal drugs protect against the development of fungi, mold;

- fireproof impregnations for fire retardant panels.

Store products in dry conditions in a warehouse, where a constant temperature and ventilation are provided.

Application area

Additives and modifiers in the composition expand the scope of application of sheets, they are mounted indoors:

- bathrooms;

- laboratories with a chemically aggressive microclimate;

- in places with increased risk of fire.

Drywall goes well with other materials, for example, with stretch ceiling inserts. Point and strip lighting is installed in wall and ceiling structures, creating unusual interior solutions. The surface is smooth, suitable for puttying and painting, as well as for wallpapering, laying tiles, and other finishes.

Varieties of GCR and their characteristics

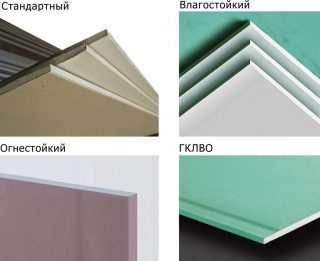

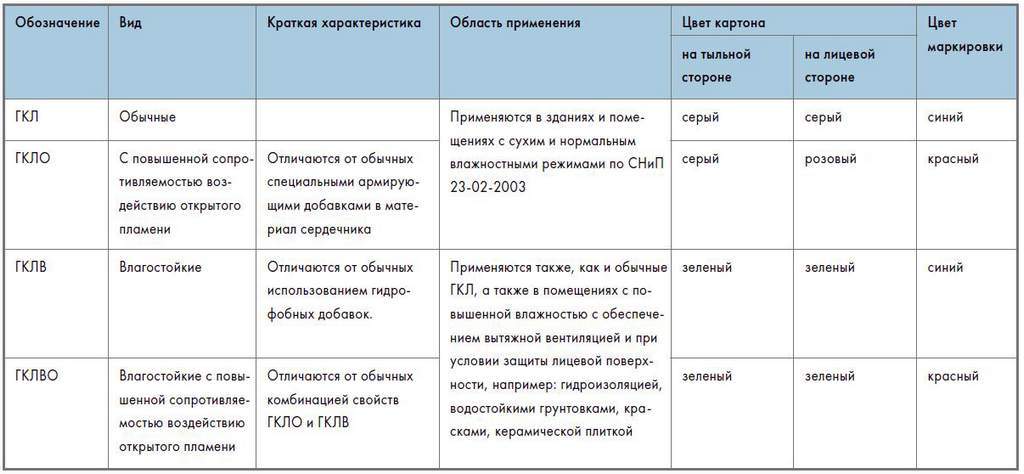

Produce the following types of drywall:

- GKL - drywall with standard parameters;

- GKLV - moisture resistant;

- GKLO - fire resistant;

- GKLVO - fire and moisture resistant;

- Reinforced;

- GKLZ - soundproof.

To the reinforced category include sheets with a thickness 15 mm, while the mounted layer can withstand increased shock and other loads. Only an electric tool is used to cut it, since it will not work by hand. In terms of strength, the material is comparable to aerated concrete, but easier to install.

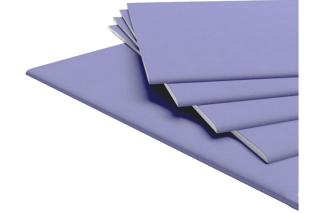

Soundproof the variety prevents excess noise from entering the house. Such panels differ great weight drywall, in comparison with standard products, one sheet has a weight of 10 kg more than usual. For ease of recognition, the soundproofing panels are painted purple. Their thickness is 12.5 mm, and the size of the gypsum board is 1200 x 2500 mm or 1200 x 3000 mm. There are also acoustic perforated drywall

The difference between ordinary GKL from GKLV, GKLO

Standard gypsum board produced for installation in living rooms, corridors, bedrooms, office premises, gde no high humidity... The sheets are gray and the markings are blue. GKL thickness for ceiling - 9 mm, for walls - 12.5 mm.

GKLV produce for installation in conditions of high humidity, their color is green or light green, and the designation letters also have a blue tint. Not only the cardboard is impregnated with hydrophobic additives, but also the inner gypsum core. Such sheets are intended for gluing tiles on them, for installation on verandas, terraces. The material is subdivided into two categories: A and B.

Plasterboard sheets produce improved quality with fire-resistant effect (GKLO)... Products are pink in color, they are placed as a cladding for fireplaces, near stoves, heating units. Material withstands open fire for 45 minutes, then begins to break down.

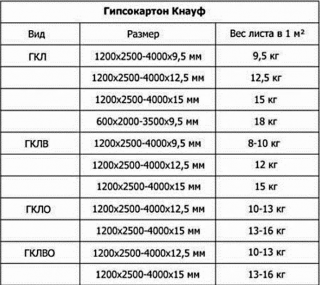

Sheet thickness and dimensions

Number of sheets in a package depending on the parameters:

- Products of minimum thickness in the package contain 62 panels, with 2 packing sheets. The total area in a pack is 186 m2.

- With a thickness of 9.5 mm, a pack contains 55 core boards and one packing list. The total area is 165 m2.

- Thickness 12.5 has a package area of 135 m2 (45 main and 1 packing list);

- With a thickness of 14 mm, a pack consists of 40 main panels plus 1 packaging, and the square is 120 m2.

As the length of the sheet increases, the thickness may increase. For example, reinforced gypsum board sheets are produced with a thickness of 15 mm and a length of 4000 mm.

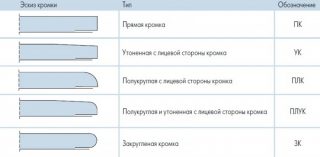

Types of edges for gypsum board

There are products on the market with different edges:

- PLUK - semicircular thinned edge;

- Of the Criminal Code - thinned hem.

First option produced by German manufacturers, and Russian ones adhere to a strict standard. UK edging is made by domestic manufacturers, its shape differs by a certain step. The semicircular joint is filled with putty to a depth of 8 mm, the width of the seam is 11 cm. The UK edge makes the seam already -9 cm, but its depth is only 2 mm. To prevent cracks on the seam, put a serpyanka tape.

Features of product installation

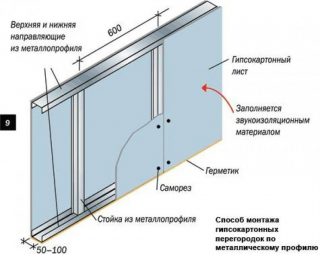

Installation rules:

- distance between profiles take multiples of 60 cm or 40 cm (for one sheet 3 or 4 runs);

- put around the perimeter of the room strapping profile, into which the ends of the ceiling slats are brought;

- to the ceiling the girders are fixed with brackets (hangers), while leveling the plane;

- cross connection gypsum plasterboard panels are made only on a profile; they cannot be joined in the air.

Before installation, sheets kept in a room for about a dayfor the products to adapt to the microclimate, this is important in winter.

If the material is mounted on glue, the plane is ideally leveled with plaster. It is not recommended to use water-based glue, even for the moisture resistant category.

Drywall selection criteria

Thickness, size along the length is chosen depending on on operating conditions... For example, if the height in the room is up to 2.5 m, sheets with a length of 2.5 m are suitable, since there will be half-meter waste from three-meter ones, which cannot be used anywhere, or additional jumpers will have to be placed across the frame under their joints in height.

Acquired the material is examinedso that the integrity of the cardboard on the surface is not compromised, especially for waterproof drywall and fire-resistant. Pay attention to the storage conditions, because with prolonged improper storage, properties and quality begin to be violated. The sheets should not be turned in the plane, all ends should be of the same thickness and not wrinkled.