Penetrating compounds are needed to strengthen the top layer of the base. Weak surfaces are found in old plaster, brick, concrete. The deep penetration primer increases the adhesion of the finish, putty, paint, wallpaper. Special impregnation is used in various works; construction, repair and decorative finishing cannot do without it.

Description and material properties

Impregnating compositions are presented on the market in the form water-dispersion solutions, with which the base is processed before leveling or finishing.

Part penetrating soils include components:

- water;

- natural or synthetic acrylic resins for bonding particles;

- polymeric acrylic or styrene acrylic additives for deep penetration;

- fungicides for imparting antiseptic properties;

- latex microparticles for increased adhesion.

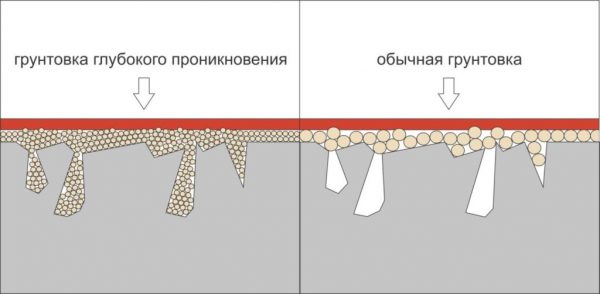

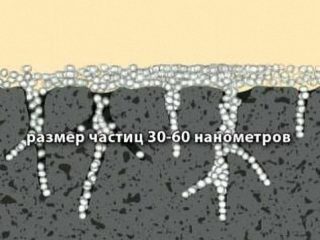

The compounds penetrate well into surfaces with large and small pores. In the second case, emulsifiers are added to the formulation so that the particle size is no more than 20 - 50 nm. For coarsely dispersed soils, the particle size is at the level of 100 - 200 nm.

Scope of application

Primer Application Cases for concrete, brick, other mineral substrates:

- on cement-sand plaster or gypsum plaster before painting;

- on putty before gluing all types of wallpaper;

- screed for ceramic tiles;

- on the walls before laying the tiles;

- to strengthen the surface after cleaning lime, chalk whitewash.

If you do not prime each layer of putty after sanding, the layers will not be bound together due to dust, so the surface will crack and delaminate.

Specifications

Technical specifications impregnations vary depending on the composition, but some indicators are common:

- acidity (pH) is 7 - 8;

- penetrate into the base by 5-10 mm;

- applied at temperatures from + 5 ° to + 35 ° C;

- the hardened film can withstand -40 ° - +60 ׄ ° C.

The soil contains a non-volatile residue at the level of 15 - 20% of the total mass, the rest is solvent (water). The film forms in 30 - 40 minutes, and the material dries completely in 3 - 6 hours. The primer dries best at room temperature and 40-60% humidity.

Varieties

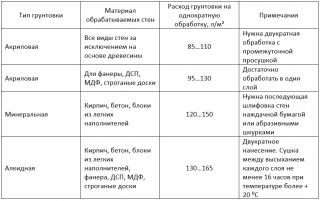

By composition, solutions are divided into types:

- polyvinyl acetate apply under paints with a similar base;

- polystyrene used for walls, ceilings, floors made of mineral materials, only for outdoor use;

- perchlorovinyl have a pungent odor, they are used on brick, plaster.

Acrylic concrete primers work well on all surfaces other than metal. Solutions are released ready for use or in the form of a concentrate. The two-component species are mixed before processing.

Criterias of choice

Primers are chosen depending on packing. Release cans of 10 liters, containers of 1 - 3 liters... For large volumes there is barrels of 40 - 60 liters. It is better to choose a one-component liquid concentrate, which can be diluted with water in a ratio of 1: 3, 1: 5, 1: 8. The first layer is made weaker in order to increase the degree of penetration into the material. The second is bred less.

Consider the type of surface, which is primed, the number of layers, the type of finish (gluing tiles, wallpaper, painting). For wood use polyvinyl acetate, polystyrene varieties. To increase adhesion to aerated concrete heavy finishes take concrete contact. The roof primed with bituminous compounds with quartz additives.

Primer application rules

The primer is applied spray guns, roller, brush. For the latter tools, long handles are prepared if the height of the room is large or they work on the ceiling. It is better not to use a brush for application for painting., since the soil is mixed with dust, and the villi leave convex grooves on the plane.

Working rules:

- the concentrate is diluted according to the instructions on the label;

- the plane is processed so that there are no surpluses and drips, as well as non-painted areas;

- corners, edge areas are smeared with a brush;

- before applying the second layer, wait for the previous one to dry.

Preparation of the base

The soil is poorly absorbed into surfaces on which there are residues of fat, oils, so they degrease using solvents: solvent, white spirit, acetone.

Sequence of preparation:

- clean the plane from old exfoliated particles of plaster, screed, putty;

- it is better to vacuum the surface to remove dust.

If you leave small debris and particles of the old coating, after hardening, such pieces will firmly adhere to the base, and it will be problematic to remove them.

Consumption of the composition

Average consumption values:

- deep penetrating impregnation of the first layer will require 100 - 120 g / m²;

- for the second and subsequent layers you need 50 - 70 g / m².

Manufacturers rating

Popular manufacturers:

- Henkel (Ceresit)... The enterprise manufactures many products, including penetrating impregnations. Products differ in quality and durability.

- Knauf. The firm associations have been producing building mixtures and primers for about 100 years. They make adhesive compositions, with a mineral filler, deeply penetrating. Users appreciate the good quality and reasonable price.

- Leroy Merlin (Axton)... The company manufactures primers for various applications, all surfaces. Experts pay attention to product testing and quality control.

The following manufacturers have shown themselves in the Russian market: Lacra, Optimist, Prospectors, Bolars, Tex, Laes.