Plasterboard is used for finishing residential buildings, offices, public premises. The material has a smooth surface, it is used for covering large surfaces and small shapes. Gypsum fiber boards differ in production technology, composition and structure, therefore they are used in conditions where the rigidity of the finishing layer and moisture resistance are required. Better GVL or GCR, it is impossible to determine unequivocally, many factors are taken into account for the choice.

Description of drywall and gypsum fiber

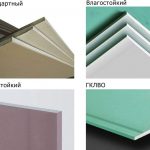

Drywall is produced with different properties:

- GKL - ordinary material, intended for a normal climate in the home;

- GKLV - moisture resistant variety, it is placed in bathrooms, the coating resists moisture;

- GKLVO - at the same time it is a water-resistant and fire-resistant coating;

- laminated sheets - contain a decorative PVC film on the front side;

- acoustic drywall - dampens noises and sounds.

Gypsum fiber sheets (GVL) represent a homogeneous gypsum mass with modifying additives, which is formed in the form of a plate. Fluffed cellulose threads are introduced into the composition, the fibers increase the strength of the material. GVL differs from GKL in that outside the panels do not have a cardboard finish.

Varieties of GVL:

- GVL - durable panels, installed in dry rooms;

- GVLV - water repellents are added to the products, so the sheets do not absorb, do not conduct moisture;

- GVLVO - super sheets of high strength, moisture and fire resistant.

Application areas of gypsum plasterboard and gypsum plasterboard

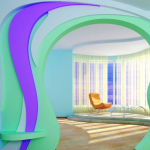

The g / carton structure allows it to bend in arches of small and large radius, while gypsum fiber board is not capable of bending. Its strength manifests itself only during compression, impact, and the material does not work for bending. In accordance with these characteristics, the areas of use of both types are allocated.

GKL is used for work:

- linear and curved wall decoration;

- the device of partitions in one or two layers;

- installation of suspended ceilings in one or more tiers;

- sheathing of slopes of rectangular and arched shape;

- installation of curved niches in the walls, facing of cabinet and built-in furniture.

Gypsum fiber panels are distinguished by a higher cost, therefore they are used in finishing when it is necessary to ensure strength, reliable coating. For finishing ceilings, GVL is used less often, since the material makes the structure of the suspended ceiling heavier.

Scope of application:

- in rooms with high humidity, bathrooms, kitchens, but the indicator should not exceed 70%;

- in basements, when arranging the interior space of basement floors;

- for upholstery of attics, attics;

- fire-resistant and moisture-resistant elements are used when decorating fireplaces, baths, saunas;

- as a roughing layer for flooring.

Plasterboard differs from gypsum fiber in that self-tapping screws and nails are securely fixed in the second material, therefore, pieces of furniture, electrical equipment, and decorations are easily placed on partitions and walls.

Technical and operational characteristics

GVL panels, when used indoors, do not emit toxic components at normal or high temperatures. Environmentally friendly gypsum fiber is allowed to be installed in hospitals and children's institutions.

Drywall is a lightweight and flexible material for various types of interior decoration. It provides sound insulation of the surface, but lower than that of fiber boards - the threads inside more effectively dampen sound vibrations.

For gypsum board, special dowels are used, which open when the self-tapping screw is tightened and provide rigidity.

The difference between GKL and GVL

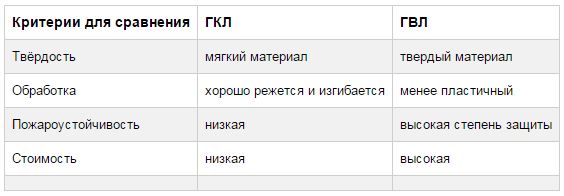

The comparison shows that the materials have difference in technical characteristics:

- G / cardboard is not placed when finishing the floor, since the material does not have durability for such loads. Gypsum fiber withstands household efforts, so it does not collapse. GKL in the gym will become unusable from hitting the ball on the walls, and the GVL will remain intact.

- Thermal conductivity fibrous gypsum material at the level of 0.22 - 0.27 W / m · C, and gypsum board - 0.26 - 0.35 W / m · C, we can say that the first type protects better against heat loss.

- GVL will be detained 35 - 43 DB extraneous noise, and drywall will extinguish only 28 - 35 dB.

- Frost resistance gypsum fiber boards - 15 cycles, and gypsum boards - 8 cycles.

The fire-technical characteristics of both materials are at the same level. Materials belong to group G1 (flammability), flammability - category B3, toxicity - T1, ability to form smoke - D1.

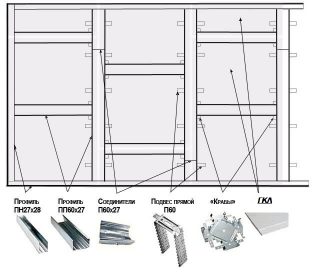

Installation features

Frame profile under drywall installed in 60 cm increments, and racks under gypsum plasterboard are placed every 60.5 cm to ensure the mounting gap between the edges. It is needed for high-quality sealing of slabs in order to provide sufficient strength corresponding to the base material.

Both materials are placed on a frame or mounted on glue.

The crate is assembled from galvanized profiles, for gypsum fiber elements it is better to choose reinforced ones. Can be used wooden slats with a section of 40 x 30 mm, but they are treated with linseed oil twice, then installed in the frame.

For the frameless method, special dry adhesive mixtures... For gypsum fiber board with a thickness of 12.5 mm with wall irregularities up to 20 mm, cement-based glue is used. The seams are sealed with an elastic mesh, putty with simple, fire-resistant or moisture-resistant compounds, depending on the type of panels.