Wooden beams are a popular construction material. It is in demand for the construction of residential buildings, outbuildings, pens for animals, small structures - stairs, swings, verandas and gazebos in the garden. During construction, the timber must be connected to each other. There are many ways to do this.

Description and scope of timber

By method of processing timber is divided into 4 types:

- two-piece - differs and aligns only from two opposite sides;

- three-cante - material processed from 3 sides;

- four-cant - all sides of the bar are even and smooth;

- calibrated - material from the driest wood, processed from 4 sides, characterized by the most accurate dimensions.

The first 2 types are used for the construction of outbuildings, baths, garages. 4-edged is in demand in the construction of housing and small architectural structures. Calibrated - the most expensive material - is used to construct buildings that must meet the highest aesthetic criteria.

The timber is distinguished and by manufacturing method.

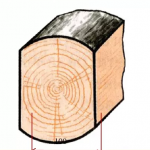

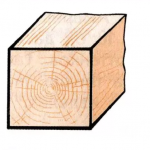

- Profiled - a bar of square or rectangular cross-section, cut from the trunk. The most popular option for the construction of residential buildings.

- Rounded - 1 or 2 sides of the lumber has a rounded shape that imitates a log. The rounded version is used for the construction of houses in the Russian style.

- Glued - it is obtained by gluing fragments of different lengths. Here the wood fibers are directed in different directions. Such a beam does not shrink and is completely insensitive to moisture, so it is actively used in construction and in the manufacture of furniture. However, it loses another advantage of wood: it cannot remove excess moisture from the house to the outside.