Flushing the gun for polyurethane foam with special cleaners should be carried out immediately after the end of manipulation with the tool. If you clean your device promptly, it will last longer. Dried particles of sealant can interfere with correct operation in the future.

Types of construction guns

The tools used to work with polyurethane foam can have a different structure. Can be distinguished two main groups:

- Budget plastic pistols. Their distinctive feature is non-separable body... Because of this, cleaning them is difficult, so usually such tools are used 1-2 times. They are purchased for renovation work, which is planned to be completed in a few days. After that, the device becomes clogged with foam and loses the ability to perform its functions as effectively.

- Professional collapsible models with a metal barrel. These devices are resistant to chemicals in foam and cleaning fluids. Therefore, flushing of these guns is not a problem if done in a timely manner. They do not lose their user qualities for a long time.

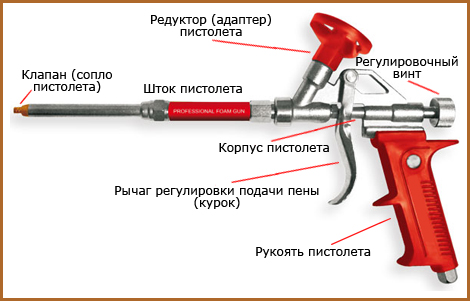

The collapsible design allows, if necessary, to replace failed parts. Usually, these models are equipped with an adapter in which the balloon is fixed, as well as a screw that allows you to control the volume and speed of foam delivery.

Cleaning methods

After removing the cylinder from the collapsible device foam accumulates mainly in the barrel... It must be removed in time until it dries. The most common way to clean a gun is use of solvents and other chemicals... It is advisable to purchase the composition of the same brand as the sealant. Solvents for both fresh and dried foam are commercially available.

Method of use indicated on the packaging of the product. Most often it looks like this:

- The container with the composition is placed in the adapter.

- The trunk is turned away from itself and the trigger is pulled.

- Continue flushing until the flowing liquid is free of foam.

Then the balloon is removed and test the correctness of the trigger stroke. If the seizure persists, the procedure is repeated. After removing the cylinder, the device is cleaned of its residues by pressing the trigger.

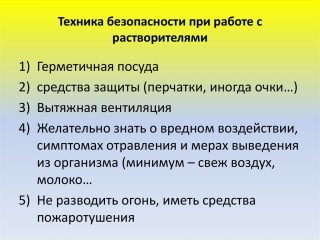

All similar the funds are highly toxic, so you need to work with them carefully. It is important to observe safety regulations:

- avoid contact with eyes and exposed skin;

- clothes should be completely closed, while hands are protected with gloves, and eyes - with special glasses;

- if the product still gets on the skin, it is washed abundantly with water, and after that it is necessary to see a doctor;

- do not carry out the flushing procedure near fire or heating appliances;

- at the end of work, hands must be thoroughly washed with soap;

- the room after the procedure is ventilated with a through air flow for half an hour.

If there is a lot of foam in the gun, it can be cleaned mechanically... To do this, you need to disassemble it. Sequence of work looks like that:

- If some of the foam on the outer parts of the pistol has already frozen, it is cut off with a clerical knife.

- Carefully disassemble the device so as not to damage its parts and fasteners.

- Each part is individually cleaned with a soft cloth.This can be done using a special solvent, acetone or nail polish remover. If necessary, use a small knife or thin wire to clean individual parts. If there is a lot of old foam on the parts, you can soak them in the product and then brush them off. You can drip a little product into the barrel to soften the dried sealant. If the gun has parts made of plastic, it is advisable to ensure that no solvent gets on them during cleaning, otherwise they may deform.

- When all parts are clean, the gun can be reassembled.

Pistol care rules

It is not difficult to take care of the device. The main thing is to clean it in a timely manner and protect it from all kinds of mechanical damage. When handling foam, it is important to observe the following regulations:

- If the sealant in the can has not yet been used up, and its shelf life has not yet expired, the gun can be stored directly with the capacity installed in it... Before that, a little foam must be drained so that it does not dry out.

- If the sealant has run out, the packaging is dismantled and the tool is rinsed. This must be done immediately, before the foam has time to dry.

- When buying a sealant from another company, before installing the cylinder, the tool is also cleaned of the remains of the old product. Foams from different manufacturers can vary greatly in composition and, when in contact with each other, form a mass that is difficult to remove.

For all work with a gun, sealant and solvents do not aim the balloon at yourself, another person or animal... This is dangerous: the composition in the bottle is under pressure.