The purpose of the end strip for metal tiles is to protect the roof from the effects of precipitation and extend the life of the roof. The absence of this part leads to premature damage to the structure. The installation of the plank takes the same amount of time as the construction of the roof. It is recommended to use step by step instructions for work.

Types and characteristics of end plates

Wind bar - a plate made of metal or plastic for installation on the ends of the roof covering. Two types of standard elements are supplied to the market - classic and segment products. There is also an L-shaped shape that speeds up installation.

Classic addons

Flat end strips are suitable for almost all types of metal profiles and metal shingles. In appearance, they are corners with a curved edge 2 meters long.

Dimensions of the end plate for metal tiles:

- Curly 90x115 mm is an aesthetic wind model that gracefully emphasizes the lines of the roof. The presence of stiffening ribs increases the strength of the structure. The market is mainly represented by manufacturers from Russia and Finland.

- The flat version 95x120 mm is an analogue of a figured product, but without stiffening ribs.

- A wide model with dimensions of 135x145 mm - used for all types of metal tiles, corrugated board, as well as the new Moterros profile. The product completely blocks the wave of the highest roof covering, providing reliable protection against moisture.

The choice of the wind bar is influenced by the profile height. For a tile or profiled sheet, it is better to use narrow elements 9x11.5 cm. The higher the parameter of the roofing material, the wider the extension should be.

Segment add-ons

It is recommended to choose segment strips for new generation roof tiles. The products are an improved analogue of the classic models. In appearance, they have a complex shape, where the narrowing occurs to the upper part, and the edges are bent not only from the end, but also from the sides.

The roofing element is versatile - it can be attached to all types of metal tiles. In addition, the plank has a step length of 350 or 400 mm - depending on the parameters of the coating.

There are left and right segment strips on the market. To understand which element needs to be mounted, you need to face the building. The outer corner of the left product will point to the left.

Materials used for the production of wind power

Fastening of end strips is carried out only on pitched types of roofs. If the building is built of concrete, its use is irrelevant. The end protector is made of the same materials as metal tiles. The main raw materials are sheet steel, copper and aluminum.

Coating options

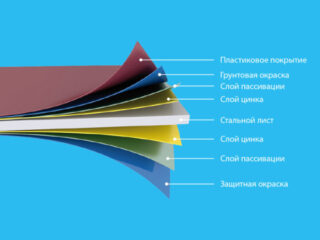

Copper does not need additional coating, so it is used in its pure form. Sheet steel and aluminum have a protective decorative coating that resists corrosion. The following polymeric materials are used as coatings:

- PVC;

- polyester;

- polyurethane;

- acrylate;

- polyester;

- plastisol.

Depending on the location of the structure, the type of coverage is selected. If the building is located in an ordinary area without industrial production, it is recommended to install additional elements with a polyester coating with a thickness of 25 to 30 microns.

End or cornice coverings are rarely used in their pure form. A mixture of components is often used to improve the quality of the feedstock.

Metal and plastic

The main raw material for the wind-up elements is polyvinyl chloride (PVC). The product's lifespan is due to its resistance to UV radiation, but it is lower than that of its metal counterpart. Installation of heat cables to these roofing systems is not recommended, since PVC loses its original properties due to temperature changes.

The second most popular material for the manufacture of end plates is thin sheet steel, which is easy to process. The filling element is produced by rolling on machines to give the required shape.

Some factories supply aluminum models to stores, however, due to the high price, they are not in demand. In addition, the metal protective system has a low level of resistance to moisture and requires additional coating of paintwork materials or solutions.

Wind extension for soft roofs and corrugated board is an irreplaceable element. Laying is carried out after waterproofing and installation of the topcoat.

End plate selection criteria

The purpose of using wind bars is to solve several problems - to protect and decorate the joints. The padding system prevents moisture from entering the rafters. The closed ends neutralize the wind loads on the profiled sheets, which increases the service life of the roofing cake.

Planks are chosen in one or a contrasting tone with metal tiles. This allows you to gracefully complete the appearance of the building, giving it integrity. When choosing an extension, they are also guided by the height of the profile of the metal tile. It is recommended not to skimp on protective elements, since the service life of the structure depends on the quality of the materials.

If you need to make a do-it-yourself wind additional element, take a galvanized sheet of steel with a width of 0.4 mm. Form a bend with a wooden mallet. However, it will not be possible to obtain factory quality, since it will not be possible to make the bend even.

Installation of a wind bar on metal tiles

The installation of the end strip to the metal tile is the final stage of the installation of the roof, including after the installation of the cornice and drain. After the wind element has been laid, the ridge is fixed on the ridge.

The nuances of attaching the end plate

The wind bar is equipped with two fastening shelves - the wider their width, the higher the level of protection of the rafters. The installation of the extension on the metal shingles is carried out simultaneously with the sealant, duplicating the waveform of the roof covering.

Installation diagram of the classic finish for metal tiles:

- Overlap the planks from the eaves to the ridge. The adjoining of one extension to another occurs at a distance of 50 mm.

- Align the fastened elements so that the bottom edge is straight.

- The extensions should be fastened to the self-tapping screws from above - 4.8x70 with a pitch of 80 mm, from the sides - 4.8x28 with a pitch of 35 mm.

The standard length of the end plate is 2.5 m. The operating parameter is ~ 2 meters. When calculating materials, it is recommended to take into account the difference. The characteristics of the additional elements are selected depending on the wave height and the width of the roof end to be overlapped.

Algorithm for fastening a segmented end plate

The segment bar must be fixed strictly according to the instructions, since this affects the microclimate of the house. Violation of the fixation algorithm leads to the creation of unpleasant rattling sounds when gusts of wind.Therefore, it is necessary to ensure a tight abutment of the extension to the roof.

The correct installation of the segmented end plates is as follows:

- Lay the extensions from the eaves to the ridge.

- The principle of alignment is the same as for the installation of classic elements, i.e. along the bottom edge.

- Fastening is carried out from the side parts and from above in the overlap areas with 4.8x28 mm self-tapping screws.

At the last stage, fix the segment strips to the end with 4.8x70 mm self-tapping screws.