To cut off the chipboard evenly, you need not only skills in such work, but also tools suitable for the task at hand. The choice of fixtures depends on the amount of work to be done, the type of plate and the configuration of the cut.

Chipboard cutting rules

Saw the sheet by hand without chipping several simple rules:

- to provide stable position Chipboard - the blade should not vibrate, and at the end of the cut, break under its own weight;

- use guide rail, rigidly fixed with clamps;

- choose a hacksaw or replacement files with the smallest teeth;

- sawing with minimal pressure;

- enjoy the most the right tool.

Sawing tools and equipment

Depending on the volume of work to be done and the configuration of the cut, they use:

- electric jigsaw;

- circular saw (parquet);

- manual frezer;

- hacksaw;

- professional equipment.

Not every tool can produce parts of the required shape.

Panel saw

If you know the exact dimensions according to which the sheet should be cut, it is more correct entrust the work to professionals. Almost all sellers - bases and building markets - provide this option. Often the sawing service is free, the customer only pays the cost of the chipboard.

For cutting, format-cutting machines of various designs are used.

Sawing chipboard without chips allows various additional devices. For example, some models have two saw blades: the first, with a small diameter, cuts through the surface laminated layer, and the main one makes a full cut.

CNC panel saws operate in a semi-automatic mode, eliminating operator errors, which makes it possible to obtain finished parts with exact dimensions up to 1 mm. This is important in the manufacture of cabinet furniture.

Jigsaw

An electric jigsaw is used to cut a sheet along straight and curly lines.

The advantages of the method:

- availability - most craftsmen have a jigsaw, and a new one is inexpensive;

- on sale there are special files for chipboard, chipboard and laminate;

- you can cut circles with a small radius;

- suitable for making through holes for hatches or wiring accessories.

To obtain a straight cut, you need to have experience with the tool or just use a guide rail.

Parquet floor

Hand circular saw, sometimes called "parquet", is used if it is necessary large amount of work for cutting chipboard along straight lines.

Purchase carbide-tipped discs.

To simplify and speed up the work, choose a parquet floor, complete with a guide rail, or buy an accessory separately.

You can do without additional details if you cut along a guide from a corner or plastering rule.

Main lack of method - impossibility to make a curvilinear cut.

Fraser

To efficiently saw off chipboard using a router, the master a lot of experience is required.

An even, flawless edge is obtained only when used diamond cutters, the price of which is great.

Hacksaw

Cut with hand saws takes a lot of time and requires a lot of physical strength.

Hand saws with large and medium teeth are only suitable for sawing normal chipboard (no laminate). The result will always be accompanied by chips and scuffs. The appearance of the edge can only be corrected with decorative overlays.

A small amount of cutting is done with a fine-toothed hacksaw. To reduce the number of chips, masking tape is glued on top of the sheet, the cutting line is marked and only then they begin to work.

Stages of work

Using an electric jigsaw is the most common option. when sawing chipboard at home, due to the availability of tools, versatility and ease of handling.

Requirements for the files used:

- small teeth;

- lack of wiring if laminated chipboard is to be cut;

- narrow blade for curly cuts.

In the assortment of most tool manufacturers there are special products for sawing chipboard. Laminate files are also suitable for work.

The sawing process consists in the sequential performance of three operations: sheet marking, sawing and edge processing, if necessary.

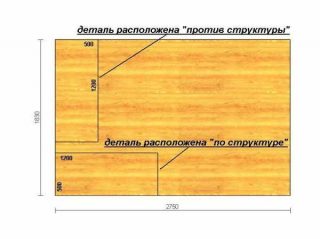

Cutting material

It is recommended to conduct planning the arrangement of parts on a sheet of lined paper. It is easy to find calculators and programs on the Internet that automatically plan the optimal arrangement of parts.

Before starting work, the sheet must be laid on a solid base, taking into account that a free space is needed under the cutting site for the file stroke.

Further, the cutting algorithm consists in sticking masking tape and drawing cutting lines with a permanent marker.

By gluing masking tape of the required width, you can eliminate scratches from the steel sole of the jigsaw, reduce the likelihood of chip formation in the laminate layer.

If it was not possible to find special saws for chipboard, sawing is carried out from the back side, so that the teeth "work" towards the surface.

Sawing process

It is recommended to cut straight lines using guides.

Work algorithm following:

- With a sharp knife or special tool, cut through the layer of laminate. The operation reduces the number of chips.

- Clamps fix the guide, on which the sole of the jigsaw will rest with a direct cut. You can do without a device if the quality of the edge is not decisive or with a lot of experience. The location is chosen based on the width of the jigsaw base plate.

- The average rotation speed of the electric motor is set, the rolling mode is removed.

- Start the cut from the edge to the center.The pressure of the tool is excluded, since in this case the file will necessarily be led to the side or the cut will pass at an angle in the plane of the sheet.

- If necessary, they carry out finishing, bypassing the workbench.

- At the end of the cut, the sheet breaks out under its own weight.

Only high-quality files allow to work for a long time. The "economy class" tool will provide cutting of no more than 5-10 running meters of chipboard, after which the teeth become blunt, chips appear, the jigsaw leads to the side.

If it is necessary to cut the inner hole for the hatch, the installation of electrical outlets or switches, markings are first carried out. Then the chipboard is drilled with a drill 1–2 mm larger than the width of the file. Having installed the file in the hole formed, sawing is carried out.

Processing after trimming

If rigid profiles are used = dust removal is sufficient. Pasting is carried out with wood glue.

Facing the end of the chipboard carried out with films made of different materials:

- veneer;

- melamine;

- PVC.

An important condition - before gluing, it is necessary to level the end surface of the chipboard.

For processing, use a milling cutter, file or grinder.

Self-adhesive films are pressed with any even bar. After gluing, the protruding parts of the end tape are cut off.

Specialist recommendations

If the tool has vacuum cleaner connection, you should definitely take the opportunity to remove waste from the cutting area, this improves the visibility of the marking, it is easier to observe the correct cut.

When edge quality doesn't matter or it will not undergo pasting, the easiest way is to use a conventional hacksaw with fine teeth for cutting, this will save money on the purchase of a power tool and consumable parts.

Tilt angle the cutting blade of a hand-held hacksaw should be kept for about 35°.

The sole-support of the jigsaw or circular saw must be flat and fit snugly into the chipboard when cutting.

When sawing laminated chipboard with parquet, if the design of the tool allows, first cut to a depth of 2-3 mm, and the entire depth is sawed in the second pass of the tool.