Curved furniture or architectural elements such as an arch or a round column seem to be much more attractive than ordinary rectangular outlines. For the construction of such items, bent plywood is used.

Features of bent plywood

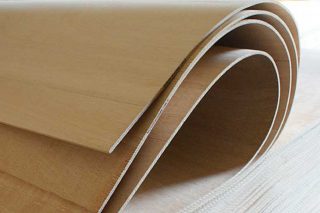

For bent high-quality plywood, use birch veneer and some conifers... Since this material is used in the manufacture of elegant furniture, the outer layers of the sheet are made of expensive wood.

Bent plywood differs from usual in characteristics:

- low density - on average 400 kg / m³, which allows further bending of the material;

- small thickness - from 3 to 8 m;

- permissible depending on the thickness of the board bending radius is from 3 to 5 cm.

You can bend the plywood and unbend it. The material will return to its original form, it can be reused in any capacity. It is impossible to bend ordinary slabs without irreversible deformation.

The best option is flexible plywood made from Ceiba, but this material is expensive. The flexibility of conventional birch is much less.

Required tools and materials

To bend plywood, you need to choose the right material. Feature List following:

- a type - flexible or bent glued;

- breed - preference is given to Ceiba wood, but in fact, birch is more common;

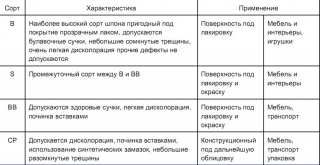

- grade - BB or CP, since such plywood is often trimmed with veneer;

- thickness - corresponds to the purpose, but it is taken into account that the thicker the sheet, the more difficult it is to bend it.

Depending on the type of material selected, a tool is selected. A clerical knife is enough to cut a sheet with a thickness of 3 mm. A slab of 10 mm must be cut with a hand saw, and over 10 mm with a jigsaw.

List of required instruments includes:

- tape measure, square, ruler;

- marker and pencil for marking;

- cutting tool - a clerical knife, a hacksaw for wood, a jigsaw;

- clamps for fixing plywood in a bent state;

- router with a set of drills and cutters;

- a sander or a set of sandpaper with different levels of abrasiveness.

If you are using non-veneered plywood, you will need varnish or paint and brushes to cover.

Plywood bending methods

There are several ways to bend plywood at home. The choice depends on the material. Narrow strips bend easily after steaming.Large slabs will require cuts and mechanical tools with a specific bend radius.

Notching

In places of folds in plywood, make tapered cuts, but not through - 2-3 layers must be preserved. The distance between the cuts is determined by the bend radius: the steeper it is, the more often the cuts are made.

The technology is as follows.

- Mark out a sheet of plywood. The average distance between future cuts is 3-4 mm.

- The sheet is sawn through on a milling machine. It is impossible to do this manually.

- The slab is then bent until it takes the desired shape.

- The cavities formed during sawing are filled with epoxy glue.

- A veneer is glued to the front side of the sheet in order to mask the cuts.

It is easier to fold plywood along the grain of the wood.

Gluing

- To get what you want, not a thick sheet is bent, but several thin or even separate sections of the tree. Cut out the material according to a template, since the fragments should be layered on top of each other and have an ideal shape.

- Bend the material by steaming, less often using incisions.

- After folding, the sheets are assembled into one piece using a special plywood glue. The assembled product is clamped in a vice. If the template is made of hard material, it can itself serve as a vice if you use a clamp.

If you only need 3-4 curved parts to make your own furniture, it's easier to order them in the workshop.

Steaming

- A thin sheet or narrow strip is left over a hot bath - a container or bath with boiling water. The retention time over steam depends on the thickness of the plywood. For a 5 mm slab, it will take up to 4 hours.

- Then the sheet is bent to the desired radius. They do this while the plywood is hot, since in this state it is more pliable.

- The product is allowed to dry for 1-2 days so that it finally hardens. It should be left in a dry room, as excess moisture prevents the material from drying out.

How to work with large sheets and complex structures

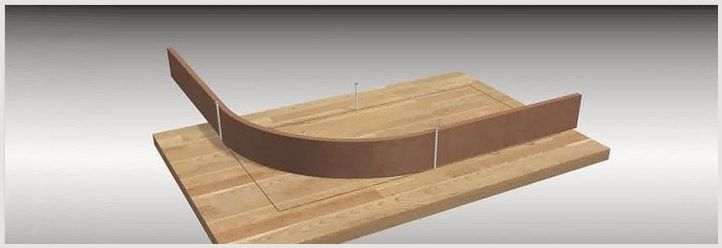

Complex configuration furniture implies bending under different degrees and radius within one strip or sheet. For such products, it is required to make a special template or frame made of beams.

- Template made of very hard plywood - parts are cut out of the sheet that exactly repeat the bending profile. Since the elements are usually bent on both sides, then the templates are made 2. Then they will be connected with spacers so that a device is obtained a little narrower than the width of the future part. The configuration of the template can be anything you want.

- For more complex cases, do frame. It is a kind of stand, perpendicular to the plane of which rather thick round bars of wood are fixed. Bars are placed at the pressure points, but do not form an exact contour. At any time, you can install additional jumpers here to clarify the shape of the future part.

When developing the frame, the type of the clamping device is taken into account. Most often it is clamps... For the jaws, the clamps on the plywood liners leave holes, and the frame itself is reinforced with additional ribs to create the necessary tensile or clamping load. In simple cases, the bendable sheet can be fixed with a cable or rope.