In two-tiered suspended ceilings, there are smooth vertical contours, which are faced with curved strips of g / cardboard. To design arched door, window openings, you need to bend drywall. Arched lines decorate wall niches and other structures in the house. The curvature of the sheets is given in several ways - it all depends on the thickness of the panel and the bending radius.

Possibility to bend in a semicircle or at a right angle

Drywall can be rounded the following figures:

- ovals and circles;

- rectangular and square elements;

- waves, steps, complex decorative positions.

To attach the arcuate elements you will need frame from wall profile CD-60... There is a special arch material made of galvanized steel. Some varieties are produced on a ready-made arch, if you made a mistake with the diameter, such a product is not suitable. Universal options are produced in the form of a straight strip with cuts of a complex configuration, which bends in two planes along a given line.

Folding tool:

- foam roller, fur or velor for soaking;

- needle roller for perforation;

- knife on g / cardboard for cuts.

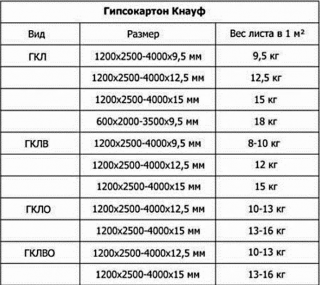

Types of drywall that can be bent

For finishing, simple gypsum boards are suitable, which are made from gypsum mass with cardboard shells on both sides. Also suitable are GKLV (moisture-resistant material) and GKLVO (moisture-resistant and fire-resistant) options. Such varieties bend more easily, since they do not have fibrous inclusions in the composition of the gypsum mass.

Variants GVL (gypsum fiber), GVLO (gypsum fiber fire resistant) and GVLV (gypsum fiber moisture resistant) differ in that inside contain reinforcing cellulose threads... Such products cannot be bent, since they do not work in bending, but only in compression. Attempting to bend such material will result in cracking.

- for a large radius (from 180 °) take massive g / cardboard with a thickness of 12.6 mm;

- medium (130 - 180 °) is allowed to be bent from sheets with a thickness of 9 mm;

- small curvature (up to 130 °) is obtained from thin 6 mm thick slabs.

The classic GCR is used more often. From the existing methods of bending, you can choose the appropriate one in terms of complexity and cost.

Basic methods of bending drywall

In appearance, drywall is fragile, but this material is flexible in certain conditions. Finishers know the tricks, thanks to which a straight sheet becomes semicircular and can be easily mounted in an arched or other structural arc.

All recommendations and rules for performing work must be followed so that the built ceiling system does not collapse. This is due to the fact that each sheet has a bending load limit, while trying to return to the starting position. If the bending technology is defective, the curved element can pull the screws out of the profile.

Professional curvature methodsdo it yourself:

- dry method;

- by soaking;

- back side incision technique.

Dry bending of sheets

Step by step process dry curvature:

- Assemble the frame, pay attention to the curved plane on which the arcuate part is placed. The profile is cut at intervals along the side walls, the step of the cut is determined empirically, it depends on the radius. Along the length of the curved arched plane, transverse parts are installed to give rigidity and additional fixation of the curved drywall.

- Measure the resulting installation location, a corresponding rectangle is cut out of g / cardboard so that its length is 3-5 cm longer than the calculated value.

- The finished element begins to be attached to the arc from the profile, moving sequentially, and fixing each laid out area with self-tapping screws.

Water bending rules

Method application process:

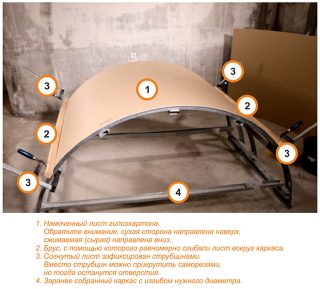

- prepare a template, use profiles, plywood, fiberboard, dock so as to subsequently fix the wet part with self-tapping screws until it dries;

- cut to size before soaking the element is rolled with a roller from the back side;

- water is applied to the perforated siderolling it with a wet paint roller, the procedure is carried out until the water ceases to be absorbed into the surface;

- the sheet is laid on the template without sudden movements, bending gradually.

Do not place the template in the sun, near heating sources to avoid cracks.

Bending of a sheet by the method of notching (breaking)

Work process:

- cut out element from a sheet according to the dimensions of the seat;

- on the face or inside out with a pencil mark cutting lines - the step depends on the steepness of the arc, the larger the radius, the less frequent the marks will be;

- cut through so that one side remains intact, use a knife for g / cardboard, a router or a hacksaw for metal.

The finished element is installed on the frame arcs, straightened, screwed on each separate section with self-tapping screws. If the segments are large, use two hardware.

The method looks less aesthetically pleasing, there is more work with it in the future, but it is quite effective, and helps out with steep arcs.