The outer corners of the roof must be covered. For this, a special element is used - a ridge. Its design and installation method depends on the characteristics of the roofing material used.

- Features of roof skates made of corrugated board

- Types of skates for roofing from a profiled sheet

- Required dimensions and characteristics of the ridge strip

- Ventilated ridge for corrugated board

- Varieties of ridge seals

- Installation and installation of the ridge on the roof made of profiled sheet

- Tips & Tricks

Features of roof skates made of corrugated board

A ceiling element is a cover strip, usually made of thin sheet galvanized iron. It is superimposed at the junction of two slopes. According to its characteristics, the part is very close to corrugated board or metal tile, therefore it does not cause difficulties in use.

The ridge element for corrugated board performs several tasks.

- It is simply impossible to tightly join the corrugated board at an angle. The gap necessarily remains, and during the construction of the roof, this means the flow and condensation of moisture rising from warm rooms. The pad prevents rain or snow from entering the joint and ensures water drainage.

- Correct installation of the ridge on the corrugated board is responsible for the efficient operation of ventilation. Steam-saturated air flows around the plank, so that it is literally pulled out from under the roof deck.

- The overlay prevents damage to the profiled sheet in case of strong gusts of wind. This is especially important on steep roofs, where a 45-degree slope provides the highest windage.

- The ridge has a decorative function. The sealed joint creates a neat, clear outline of the ramp.

On a complex roof, you need to put a special streamlined skate.

Types of skates for roofing from a profiled sheet

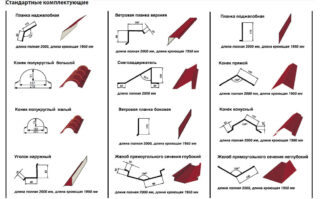

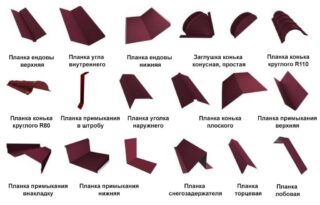

The ridge for a roof made of corrugated board according to GOST is very simple. The most common types of overlays are:

- Triangular ridge for profiled sheet - looks like a reverse gutter with an opening angle of 100 degrees. The edges of the strip are folded back and folded to increase the rigidity of the element.

- V-shaped - a bar in which there is a U-shaped median canal. It is installed in areas where a tight joint is impossible.

- Round - escutcheon with support shelves. This option is universal and can be mounted on any roof. It is believed that this modification retains heat better.

The round plate prevents water accumulation more effectively. However, in frosty weather, the resulting water film flows down to the surface of the corrugated board.

Required dimensions and characteristics of the ridge strip

The most important parameter of a product is its height. Special tables have been developed that allow you to easily calculate what size ridge to choose for a roof made of corrugated board.

Calculations are performed according to the formula H = 0.5 * B * Kwhere:

- H - pad height;

- B - the width of the building;

- K - correction factor depending on the slope angle.

The dimensions of the shelves for the triangular model are 140-145 mm. But if the slope is very steep or, conversely, very small, take the option with shelves of 190-200 mm.

The profiled linings are 115–120 mm wide, the stiffener height is 30–40 mm.

All types of skates have a rolled edge, 10-15 mm wide. This avoids subsidence and damage to the bar during installation.

Triangular escutcheons are available in lengths up to 3 m.The standard profiled in length reaches 2 m.

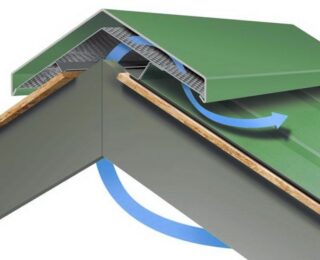

Ventilated ridge for corrugated board

When making a profiled sheet, the workpiece is covered with a protective zinc layer, and then with a decorative polymer coating. These materials prevent corrosion. However, with too high humidity, they also become unusable. This situation occurs when there is poor ventilation in the attic. In this case, the important air circulates slowly and has time to cool down on the roof surface. The resulting condensation remains on the inner surface of the groove and the outer surface of the slopes.

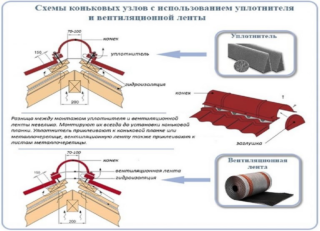

To prevent such a situation, a ventilated ridge is installed on the roof made of corrugated board. Its essence is to create an additional air gap in the outer corner.

When installing a simple gable roof, an ordinary triangular ridge is placed on the support bar of the sheathing. The slots are sealed with sealing tape. In this case, the profiled sheet does not fit together, and the resulting space is sufficient to improve air removal.

With a shallow angle of inclination, a perforated frame is equipped in this area and an overlay is placed on it.

In difficult cases - hip, hipped roof - preference is given to a profiled or round ridge, since it assumes a larger internal space by default.

Varieties of ridge seals

To increase the density of the joint, it is necessary to use sealing materials, but they also increase air resistance, which makes ventilation less effective. It is necessary to find the right balance between these requirements.

Builders recommend using geotextiles as such. The fabric is folded in several layers and stitched along the edges with an aluminum strip. A layer of butyl rubber is applied to the aluminum, which ensures the fastening of the seal to the profiled sheet.

The seal prevents insects and rodents from entering under the ridge. In addition, without a seal, the steel strip of the lining freezes more.

Installation and installation of the ridge on the roof made of profiled sheet

- Measure the length of the joint and cut the profile to size. Use a grinder or metal scissors. The cutting line is sprayed with paint.

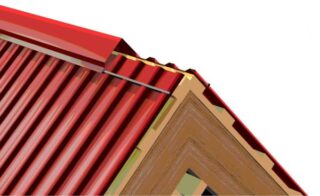

- Before installation, the crate and rafters are reinforced. To do this, two boards are attached parallel to the run on both sides.

- Lay the profiled sheet. In the run, the sheets do not fit tightly. A gap of 45-60 mm is left between them.

- The installation of the pad is started from the leeward side. Fix with self-tapping screws. The overlap line must be treated with a sealant.

To prevent water from flowing under the pad, you can pre-roll the sealing tape along the installation line.

Tips & Tricks

The ridge strip for corrugated board itself looks neat. However, this only applies to industrial products.

Often, when building with their own hands, they try to reduce the estimate, saving on additional elements, and make them independently. Unfortunately, the curved strip of steel from the remnants of the roof does not replace the ridge.

This option is applicable when building a barn or poultry house, but not a residential building.