Modern building materials require strict adherence to technology during construction and further operation. It is permissible to do the installation of a terrace board yourself, but first you need to familiarize yourself with the nuances of the work.

Decking purpose

Terrace board is intended for finishing the floor in building structures exposed to climatic conditions: balconies, open loggias and terraces; the material makes the porch of the house safer in any weather.

Finishing of walls and ceilings is not excluded, if such an option is provided for by design.

Types of material

For the manufacture of natural decking use larch, teak, pine, ash lumber. The exotic includes products made of azobe, iroke or massaranduba, hornbeam, etc.

The upper surface is made of corrugated (corduroy), smooth (planken) or textured. This makes the material less slippery, which is important in open spaces.

Artificial terrace boards are made from wood-polymer composite, hereinafter - WPC. The composition of the products consists of 30% wood flour, pigment, polymer thermoplastic binders and plastic fillers.

There are 2 classes of WPC performance: for domestic use (terraces, gazebos, balconies, piers) and for business purposes (cafes, trading floors, places of mass recreation).

Basic rules for laying

Even the presence of protection does not guarantee long-term use of wood and polymer products when exposed to precipitation, sudden temperature fluctuations and sunlight. Wood and polymers get wet, saturated with moisture, change geometric dimensions due to thermal expansion, which affects the service life.

To reduce the negative impact, it is necessary to lay the decking, observing the mandatory rules:

- the base is carefully prepared, it must be smooth and durable;

- logs and even more so the board should not come into contact with moisture for a long time - this will exclude wetting and rapid decay;

- to remove moisture from rains and melted snow, drainage and drains are installed under the decking;

- free space is provided under the flooring to ensure air circulation;

- the minimum slope of the surface cannot be less than 1%, which will ensure water flow;

- for fasteners choose hardware with an anti-corrosion coating.

When buying a board and additional elements, you need to familiarize yourself with the certificates confirming the quality of the material.

Tools and materials

In order not to waste time searching for the missing tool and the necessary components during installation, everything you need is prepared in advance.

You will need:

- drill or two-speed screwdriver;

- building level, it is advisable to have a laser tool if the size of the site is large or bubble for small rooms;

- a set of drills and bits of the required configuration;

- building corner, tape measure, pencil;

- file for wood with fine teeth;

- serviceable electrical extension cord;

- construction clamp for fixing during open installation with self-tapping screws.

From materials they acquire:

- terrace board;

- mounting (support) beams, they can be made of different materials, including aluminum;

- plugs and end strips (corners);

- starting mounting clip;

- intermediate brackets, their other name is in-line clamps;

- adjustable supports;

- galvanized self-tapping screws in the required quantity.

Supports are acquired after preparing the base, when it will be clear what height of the products will be required to level the lags. The size of the cleats depends on the thickness and construction of the board.

Arrangement of the base

The type of facility and operating conditions affect the choice of the base for the decking. There are three options, among which you can always choose the right one: on a sand and gravel cushion, on concrete, on a wooden or metal frame fixed on piles.

Sand and gravel base

Small-sized decks in private plots and summer cottages are placed on sites covered with a mixture of sand and gravel. This is the least expensive option for preparing the base.

Step-by-step installation instructions:

- The site is cleared of debris, vegetation remnants, roots of perennial plants. If this is not done, then in the future it is possible to germinate through the gaps in the flooring of grass, bushes and trees.

- Remove the top fertile soil layer.

- Fill the site with a mixture of sand and gravel of the middle fraction, tamp the pillow.

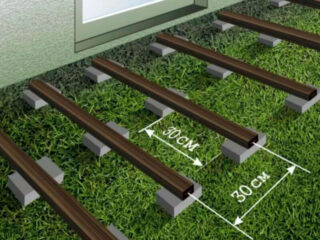

- Concrete slabs with dimensions of 300x300x40 mm are laid out along the lines of the location of the lags. You can use paving slabs. It is important to align the pads one level at a time.

- Lay logs for DCT, under which rubber gaskets can be placed to eliminate vibrations and squeaks.

- Align the logs in level, taking into account the slope for the water drain, then you need to attach them to the concrete parts.

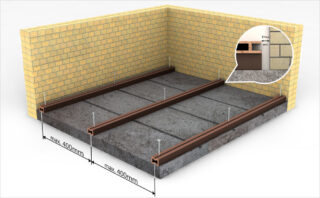

The optimal step distance of the log is 400 mm.

A more costly, but quick way to prepare the base is to put logs on the cross beams from a profile pipe with a cross section of 60x40 mm.

Before laying metal products, it is necessary to protect them with an anti-corrosion coating - treat them with a primer and apply 2-3 coats of paint for external use.

Concrete base

In areas where the soil is prone to heaving, and in cases where the flooring will be heavily loaded, it is advisable to concreate the area for the decking.

Arrangement procedure:

- Mark out the site.

- Remove the top layer of soil to a depth of 15 cm, remove plant roots.

- The resulting pit is filled with sand 8-10 cm, spilled with water and tamped to shrink.

- Formwork is built so that the height of the finished foundation rises 5-15 cm above the total soil surface.

- Lay road mesh or reinforcement with a diameter of 8 mm in increments of 15x15 cm.

- The formwork is poured with concrete of the M100 – M150 grade, depending on the expected load. When leveling, provide a slope of 1% towards the water drain.

Lags WPC 40x40 or profile steel pipes 40x60x3 mm can be laid directly on the concrete surface in increments of 40-50 cm, but they must be subjected to anti-corrosion treatment. The step of fastening to the surface is 50–60 cm. About a meter later, rubber cushions are placed to minimize the unevenness of the concrete screed.

A preferable option is when the joists under the flooring will be laid and attached to adjustable supports. In this case, the products will not come into contact with water from precipitation, and the gap between the base and the deck will allow moisture to evaporate faster, which will extend the service life.

Frame on piles

On heaving soils, it is possible to make the base on piles. Purchased screw products are used, piles are built from ceramic bricks, or the formwork is poured with concrete.

The first option is preferable since the process does not take much time - you can screw in the piles with your own hands, and set the desired level by cutting pipes.

The distance between the piles is chosen from 2 to 4 m.A product with a diameter of 57 mm can withstand a load of up to 1500 kg, and a product with a diameter of 75 mm - up to 2.5 tons, which is more than enough for a reliable installation of the flooring.

After aligning the sections, support pads for the logs are welded to the piles. All support nodes are connected with sections of a profile pipe with a cross section of 40x60 mm, to which the lags are attached to the installation lugs under the terrace board.

Depending on local prices for rolled steel and lumber, it is permissible to use a wooden beam with a section of 100x100 mm for strapping, which is pre-treated with fire-retardant compounds and painted.

Decking technology

After laying the lags for their alignment and fastening, proceed to the installation of the terrace board.

Due to the ability of decking to change its dimensions with fluctuations in temperature and humidity, when laying decking, compensation gaps are left:

- from all fixed surfaces - walls, columns, curbs - at least 30 mm, regardless of whether the board is adjacent to the end or longitudinal side;

- between the boards 3-4 mm;

- at the end joint of two products - 5mm;

- the maximum overhang of the decking outside the log is no more than 40 mm.

Manufacturers' instructions recommend placing the first board away from a fixed wall or curb. At the same time, installation is perpendicular or at an angle (diagonally).

Concealed installation

The first profile is secured with starter clips and intermediate clamps. The spiked side of the board should be facing the wall.

Use galvanized screws or screws with a thickness of 3.5–4.5 mm. If the logs are made of wood or aluminum, then a hole must first be drilled 1 mm less than the diameter of the fastener.

Self-tapping screws should not be tightened with excessive force, leaving a small backlash, which will prevent hardware breakage during sudden temperature fluctuations and in severe frosts - the coefficient of thermal expansion of steel, wood and WPC is very different.

Next, the subsequent boards are laid, securing each row with clamps. Due to their structure, they "automatically" set the required clearance.

Open mount

A wooden smooth deck, as a rule, does not have protrusions and grooves, therefore, it is fastened in an open way with self-tapping screws.

First, the first board is mounted. Before fixing the parts, they must be drilled through and through - this will exclude chipping and the appearance of cracks. The length of the hardware is chosen 35–40 mm more than the thickness of the board.

Before attaching each next element, a 4 mm thick gasket is installed between them to ensure an expansion joint. For convenience, the boards are attracted with clamps.

The final stage

The finishing of the decking flooring consists in the installation of decorative corners or finishing plinth made of WPC, plastic or PVC. Details are fastened with self-tapping screws.

Hollow WPC boards are closed with special plugs purchased for a fee.

After installation, it is advisable to cover wooden products with varnish, paint, oil or wax. The finish should be chosen based on the operating conditions.

WPC porch

It is advisable to make the base for the porch from a 40x40 mm profile pipe.

It is necessary to mount the frame on the ground using the same technologies as for flooring. If steel pipes are used, then welding is used for the connection, and the galvanized profile can be fixed with self-tapping screws or blind rivets.

For cladding, special WPC boards are used for steps and risers.

The geometric dimensions of the frame - the height and width of the steps - depend on the width of the products available for purchase.

The initial installation of the side panels is considered correct. Installation of steps starts from the top board, then the riser is installed. Further, the wiring diagram is repeated.

It is necessary to fasten the boards from the inside to the pre-welded metal corners.

The construction of the porch is completed with the installation of decorative platbands.

Frequent mistakes

When installing decking with their own hands, inexperienced builders make standard mistakes:

- laying logs and boards on the ground;

- careless attitude to the arrangement of drainage;

- lack of anti-corrosion protection of metal frames or installation of wooden elements without antiseptic treatment;

- installation in hot or cold weather when it is difficult to maintain the required clearances;

- selection of decking without taking into account the load;

- increased distances between lags.

Decking made of decking will last a long time if materials suitable for the operating conditions are used. It is important to take into account all the nuances of installation that can affect the quality and appearance of the building structure.