The fencing of the site has a protective and aesthetic function. The structure of the profiled sheet is notable for sufficient strength, presentability, ease and simplicity of installation, insensitivity to moisture and ultraviolet light. Self-tapping screws for a profiled sheet fence play an important role in ensuring its resistance to wind and mechanical stress.

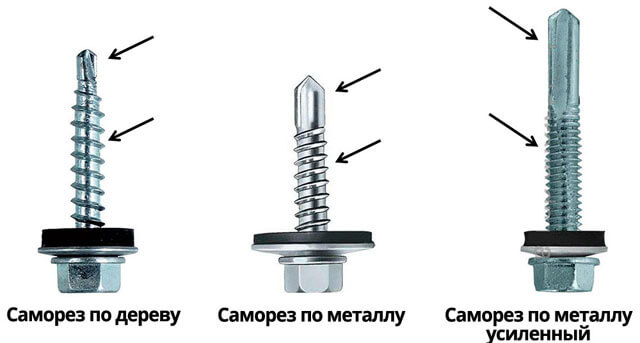

Types of self-tapping screws for profiled sheet

Self-tapping screws for profiled sheet for the fence are products consisting of a threaded rod and a hat with notches for twisting. Used in manufacturing zinc-plated alloy steel. Some models are coated with paint and a decorative polymer layer. To achieve tightness, it is used washer and elastic pad.

The following is adopted classification of self-tapping screws for corrugated board on the fence:

- Increased strength with frequent threads... Hardware for working on a frame made of pipes is additionally equipped with a drill, which makes it possible to mount without preliminary drilling holes. They are screwed into the frame through the flooring.

- Medium strength... Designed for fastening to a wooden frame. They have an increased thread pitch and a long length. Before fastening, holes are made in the sheets to soften the entry.

- Elongated. Serve for fixing sheets in places where they are located at a distance from the crate. Subdivided into categories of work in metal and wood.

Used as a cushioning material silicone and vulcanized rubber... The second type of material is more resistant to ultraviolet radiation and is designed for a long service life.

Technical characteristics of self-tapping screws

The hardware is strong and solid, as it passes heat treatment... Carbon or stainless steel is used as raw material. Further processing protects the products from corrosion.

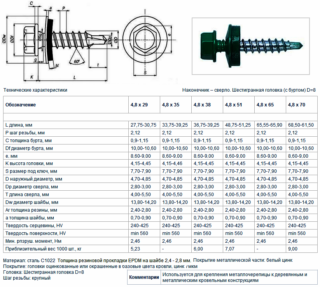

The main specifications self-tapping screws:

- the minimum thickness of the zinc coating is 12 microns;

- diameter of the threaded rod - 3.5-6 mm;

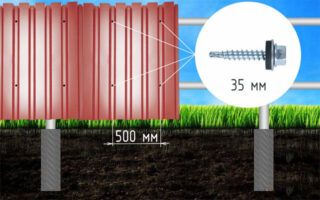

- length - 29-150 mm;

- unit weight - 10-40 g;

- tensile strength - 100-150 kg;

- packing volume - 250, 1000 pcs;

- consumption of self-tapping screws per 1 m² of profiled sheet - 8-12 pcs.

Number of screws on a corrugated sheet for a fence is determined by the brand of material, frame material, height of the canvas and the calculated wind load.

Mounting features

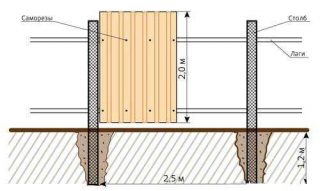

The durability and integrity of the fence directly depends on the correctness of the frame assemblies and performed fixation of sheets on it. Installation of the deck can be started after the concrete has gained strength and anti-corrosion treatment of the battens. Then you need to prepare materials and equipment.

For work you will need:

- screwdriver;

- a hammer;

- core;

- tape measure, level, marker;

- hardware in the right amount;

- rivets

Sheets are stacked with an overlap on one wave.In places where there is a difference in height, step ledges are made.

- Before installing on panels markup is done. In the attachment points, recesses are made with an awl or core, depending on the thickness of the coating.

- After attachment to the crate, screwing in the central top hardware... After vertical and horizontal correction, the rest are screwed in.

- Fastening is carried out along the inside of the wave... If it becomes necessary to fix the height of the ridge, rivets are used.

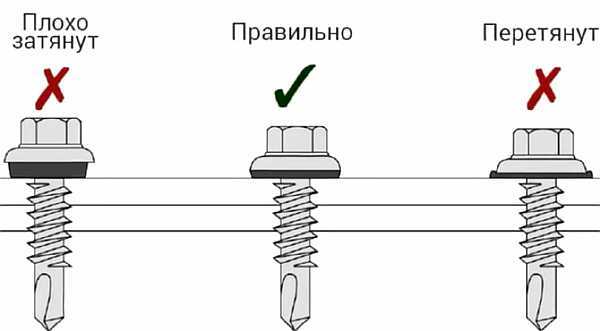

- The screw is kept strictly perpendicular to the surface... The clamping force is set on the screwdriver regulator. It should be such that the thermal washer fits snugly against the sheet, but does not deform.

- The wooden beam of the frame, the hardware must pass through... If the pipe is made of iron, the screw drills only the first wall, going beyond it by at least 3 mm.

If the self-tapping screw breaks, a plastic plug is installed in this place.

Choice of mounting color

There are two options - plain and contrasting headbands... Since the most common are green and brown sheets, mass production of fasteners has been established for these colors. If the fence is gray, just galvanized hats will look good on it. Black is considered a universal solution for all shades.

It should be borne in mind that colored items cost 3-5 times more expensive than galvanized analogs. Their price is in the range of 5-8 rubles per piece, while the painted ones can go up to 30. Considering that the expense of consumables will go to thousands, one should think about the advisability of such a design.

The number of screws needed per sheet of corrugated board

When installing a fencing from a corrugated board, you must adhere to the golden mean in terms of the density of fasteners... Their lack will lead to a decrease in wind resistance, and an excess will lead to a deterioration in tightness. It is empirically calculated that the optimal consumption is considered to be 5 pcs / m² and 9 pcs / sheet.

To get it right calculate the amount screws on a sheet of corrugated board, you can use by the following methods:

- By total floor area... You need to measure its perimeter, multiply by the height and divide by 5. You get the total number of hardware. It remains to round it up to the volume of the package.

- By the number of sheets. Their number is calculated mathematically or according to the scheme. The resulting value is already divided by 9. Then the same operation with the calculation of the packages.

There is no need to take a large reserve, since losses are possible only in snow or tall grass, and they break when the unit is installed.

General rules for fixing corrugated board

For installation you need at least two peoplebut three is better. It is more convenient to work when two are holding the panel, and the third is fastening the hardware. Without fail, everyone must be in tight clothing, shoes, goggles and gloves... The edges of the sheets are sharp and can injure a person.

Along the frame, depending on the season, snow and grass are removed, if necessary, scaffolds are laid. Then the string is stretched, indicating the top of the fence.

Depressions are made on the sheets, and in the case of mounting on a wooden beam, holes. The part is set to the mark. Carefully confident movements, it turns until it deepens and is fixed, then the effort increases. In order not to deform it, the speed decreases towards the end of the process. The process is repeated until the last piece of flooring is installed.