Cellular polycarbonate is distinguished by its presentable appearance, good flexibility, lightness, low thermal conductivity and durability. The last factor depends not only on the quality of the panels, but also on the correctness of their laying on the frame. Ignoring the technology of installing polycarbonate sheets will inevitably lead first to a deterioration in their appearance, and then to destruction.

Features of attaching polycarbonate to the greenhouse

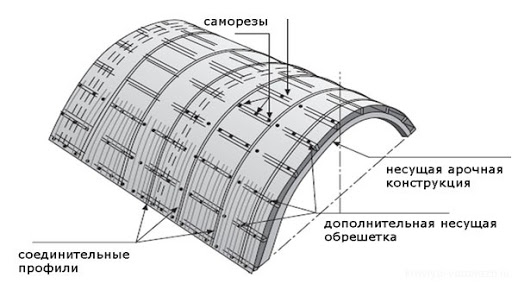

Decision to put polycarbonate for greenhouse allowed to radically change the view on the maintenance of subsidiary farming. The ability to accept arched shape provides structures with a high degree of resistance to wind and snow loads. Each manufacturer cares about the quality of their products and develops recommendations for rules for handling panels.

There are not many of them, but they are all fundamentally important:

- The edges of the slabs are connected exclusively on guides.

- The canvas is fixed on the frame special self-tapping screws with thermal washers, and under the flooring is fixed sealing strip.

- Pressing is performed at the joints split profiles leaving a gap for thermal expansion.

- Bend slabs allowed only along the honeycomb respecting the manufacturer's minimum radius.

- The ends of the slabs are closed ribbons, and a profile is put on over them.

- You need to fix the sheets right side up.

- Plates are placed only in vertical orientation with a slope corresponding to the design and the expected load.

You can lay the panels on a wooden or steel frame... There is no fundamental difference here. The only question is the strength and durability of the structure.

Why is it important to properly fix polycarbonate

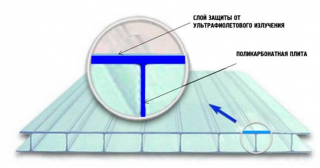

The front side of polycarbonate has UV protection, absorbing up to 99% of radiation destructive for plastic. It is worth laying it the other way around, and after 3-4 years the plate will become cloudy, cracked and become brittle.

The coefficient for metal and polymer is different. When the temperature drops, the slabs should slide over the frame. To prevent the flooring from being scratched, a soft gasket is placed under it, and the fasteners are made floating.

Which side to attach cellular polycarbonate to the sun

On sale you can find panels that do not have a film on the surface... Their immunity to ultraviolet light is ensured modifiers, evenly distributed throughout the polymer mass. But here, too, one should not assume that the side does not matter.As a rule, gloss and dusting is applied to the outer surface, which protects the boards from abrasive substances. They need to be laid with this side up.

How to determine the front side

Verified manufacturers pack their products in thick paper or polyethylene... They are applied markingincluding pointing to the front... Sometimes the panels are simply wrapped in a dense material, on which there are no signs. And this is not a problem.

there is several ways to determine which surface is the outer:

- If one side is smooth and the other rough the last is the front.

- By plate thickness... Due to the application of PVC, the outer film will be thicker. You can determine this with an ordinary caliper.

- According to the degree of wear. This is a used material. You can determine the front side of polycarbonate by scratches and abrasions that always occur on the outer surface.

After removing the panels from the packaging, it will be useful to mark them with a marker so that later you will not be mistaken. The marks are easy to wipe off with alcohol later.

Tips for laying polycarbonate

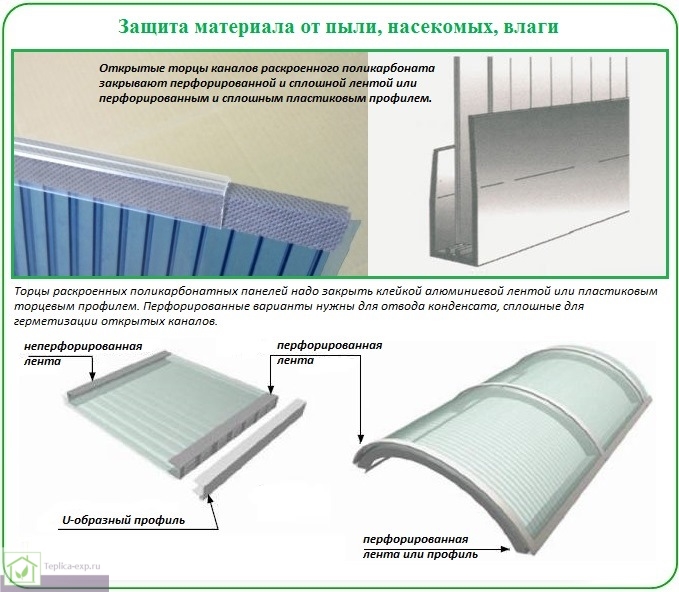

End parts panels represent open cavities. If they are left in this form after the end of installation, dust, small debris and insects with their waste products will penetrate inside. Unprotected honeycombs very quickly take on a completely unpresentable look.

Top cut sealed with waterproof aluminum tape, and lower membrane tape that releases moisture from the inside, but blocks from the outside. Puts over the edges end profile made of plastic or aluminum... Products protect the edges of the slabs from mechanical damage and give them a finished look.

How to screw

To attach sheets to the frame, use special roofing screws... They differ significantly from products for interior work. Polycarbonate hardware consists of from a threaded rod, a head like a bolt and an elastic gasket... Self-tapping screws for wood are longer, for metal are shorter, but they have a drill on the rod for screwing in without pre-drilling a hole. The heads are left zinc-plated or painted. To protect against moisture, they coated with a polymer substance... Such products are more expensive, but their service life is an order of magnitude longer.

Is it worth removing the protective film

The film applied to the panels serves for marking and to protect against mechanical damage during transportation. You cannot leave it on the stoves for good.since the coating does not provide any benefit for the facing material. Moreover, over time, it will turn white, tear and begin to lag behind the surface. Do not remove it before placing the sheets on the frame. It is better to remove it from an already fixed panel. First, you need to remove a part of the cellophane around the holes for the self-tapping screws so that the thermal washer is pressed directly against the polycarbonate.

Polymer panels have a high coefficient of thermal expansion. So that they can move freely along the frame, they need to pre-drill holes 3-4 mm larger than the diameter of the rod. After that, you should clean the pores from chips using a compressor.The best result in terms of aesthetics and tightness will be achieved if the edges of the sheets are fixed on plastic or aluminum profiles, and on the frame with sealing tape.