Arrangement of the roof is not complete without a curtain rail for metal tiles. The element refers to additional parts and is responsible for the safety of the structure, joining separate sections of the roof. For self-installation of the overhang, it is recommended that you familiarize yourself with the installation technology.

- The relevance of the eaves for metal tiles

- The difference between the plank and the drip

- Pros and cons of eaves

- Varieties of eaves for metal tiles

- With internal moisture wicking

- Classic version

- Eaves design

- Size range of eaves for metal tiles

- Installation of the eaves plank

- Instruments

- Technology

- Recommendations

The relevance of the eaves for metal tiles

The strength and service life of the roofing depends on the correct installation of the strip.

The overhang also serves as a decorative function, creating a complete image of the structure - the roof takes on an aesthetic appearance. Cornices are chosen in a single color with metal tiles, but often designers offer contrasting solutions.

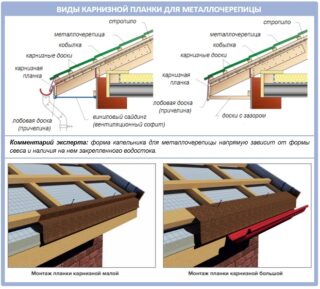

The difference between the plank and the drip

When installing roofing elements with your own hands, errors often occur with the definition of additional parts. The bar is often confused with a drip. Installing this element instead of a cornice reduces the service life of the roof structure.

The fundamental difference between the parts lies in the place of installation and the purpose. A drip tip is necessary to drain condensate accumulated on the waterproofing film. It also protects the wood from moisture. The drip is mounted on the rafter system for vapor barrier.

There is a sequence in which these parts are installed. The eaves strip is attached to the metal tile. Drip on an unprepared roofing cake directly to the rafters. At the same time, it does not adjoin the timber, but hangs down a little and is discharged under the gutter of the water drain.

Pros and cons of eaves

Consumer demand for a cornice strip for corrugated board and metal tiles is due to the advantages of the material and the technical absence of shortcomings. The clear advantages of overhangs include:

- Protection of floors and attic from the external environment.

- Sealed roof joints for walls, pipes and shafts.

- Protection of lumber used in the roof structure, which helps to neutralize the risk of fire spread. In general, the use of eaves complies with fire safety standards.

- A wide assortment line of colors allows you to choose an overhang to any shade of metal tiles.

- Correct installation of planks during the construction of the roof and adherence to the peculiarities of installation ensures a stylish appearance of the house, and also extends the life of the roof.

The disadvantage of using strips is the cost of the material and the time required for installation. Works require specialist skills and equipment.

Varieties of eaves for metal tiles

With internal moisture wicking

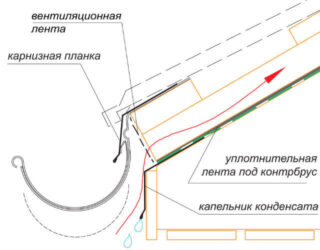

Eaves strip for profiled sheet with internal moisture drainage is an element necessary for vapor barrier of the roofing system. Installation is carried out by cutting in the center of the rafter beams.Insulation for metal tiles does not fit in this area, therefore, condensate almost does not accumulate. Moisture drips through the plank sheathing. In order to avoid icing on this part, the roof must be lined with wooden battens.

Classic version

Classic models are most often used when installing a roof, including a hip roof. This option has a 120 ° bend, with sides of 110-120 mm and 60-80 mm. The overhang is relevant for regions with a temperate climate, where there are no strong winds and high humidity. Condensation is removed by air currents circulating at the ends of the cornice.

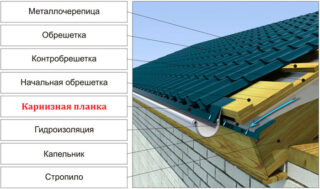

Eaves design

- lower edge;

- ramp wind board;

- drip;

- plank.

Eaves eaves construction - a set of waterproofing layer, vapor barrier lathing and metal tiles.

Part of the vapor barrier material is removed and mounted on the drip tube. Ventilation ducts are formed between the roof covering and the frame for the inflow of air masses. A cornice strip must be installed on top of the receiving window. Roofing works are completed with the installation of a drain, fixed on special hooks.

The overhang device also includes gutters, soffits and a protective mesh.

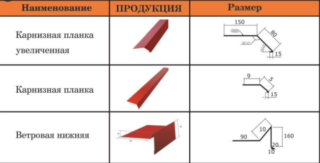

Size range of eaves for metal tiles

If composite compositions are used for cornice finishing, the surface is treated with basalt chips. The length of the overhang is in the range of 50-60 cm. Due to the fact that the extension is installed on the roof, separate parts of the required size are used for its installation.

The end strip technology is identical to the production of sheet metal tiles. Fastening is carried out from the ends of the slopes to protect the crate from moisture and reduce the wind load on the structure. For this reason, the element is often referred to as a windblown.

Installation of the eaves plank

The time for installing the eaves overhang is equal to the labor costs for the installation of metal tiles. This process requires construction skills and a drawing of the roofing system. Correctly carried out work and careful installation of add-ons affect the final appearance and tightness of the roof. The cornice plank belongs to the middle price segment, but at its expense it is possible to qualitatively protect the structure.

Instruments

Before installing the add-on element, calculate the angle of inclination and the required dimensions. Prepare installation tools before work:

- eaves overhang;

- a hammer;

- roulette;

- self-tapping screws with a flat head - from 8 to 10 pcs per running meter.

Regardless of the protection of the roof with metal elements, it is recommended to pre-treat wooden elements with impregnations or paintwork materials.

Technology

The installation option from the Finnish manufacturer RANILA is considered a simple and reliable method of installing a roofing strip. However, this technology is suitable for harsh climates with low temperatures. For mid-latitudes, the classic installation is recommended.

Prepared equipment is required to install the eaves planks. Installation takes place in five stages:

- The overhang must be bent from the side of the end of the building. On the long edge, back off 20 mm. At the top, make a notch for the fold line. Remove the resulting rectangle.

- Cut a rectangle at the flange section using the same dimensions. Bend the formed sidewall at 90 °. Thus, the strength of the fasteners is increased.

- Place the corner on the batten or support, aligning the fold with the outside edge of the batten.

- Draw two lines along the upper edge of the molded part - place the first from the eaves at a distance of 1/3, the second - 2/3.

- Proceed with the installation of the eaves overhang to the metal tile. To do this, take nails or flat head screws. The first element should be fixed on line No. 1 with a distance of 20 mm from the edge of the end. Set the subsequent self-tapping screws at a distance of 30 cm from the previous one. On line No. 2, drive in nails in a checkerboard pattern with respect to row No. 1. The first self-tapping screw must be driven in at a distance of 17 cm from the end edge.

The formation of gaps when installing eaves strips is not allowed. Therefore, they are laid with an overlap of up to 1 cm. An additional nail is driven in at the joints to increase the reliability of the structure. The last overhang of the end side is bent and fastened with a self-tapping screw, stepping back from the edge 2 cm.

If the angle of inclination of the roof exceeds 45 °, the installation area of the ridge board and the option for attaching the ridge may differ. The installation method depends on the slope of the slope.

Recommendations

The main violations of the technological process occur at the stage of installation of the vapor barrier sheet and the drip. As a rule, they try not to put the film behind the bar, but to lay it at the level of the metal lining of the cornice. In such a situation, the drip system always remains dry, but the condensate will go under the roofing sheets, forming puddles. This is due to the fact that moisture will not be able to overcome the rise through the bar.

Another popular mistake is installing a vapor barrier film without adhesive tape. For this reason, the canvas will slide down to the bottom of the rafter system or sag, exposing the insulation. In such a situation, the heat insulator will quickly become unusable due to exposure to moisture.

If no tape is available, a waterproof sealant or adhesive may be used. In this case, the canvas should be laid on wooden slats, leaving a margin of 50 cm on each side. Thus, compensation for the natural deformation of the material occurs.