Modern building materials are valued for their strength, durability, as well as for their high heat-retaining properties and affordable cost. An example is cinder block - a type of lightweight concrete.

Building a house from cinder blocks

All the features of the cinder block are associated with the manufacturing technology and the materials used for this. Besides ordinary concrete and cement, sometimes with gypsum and lime, it contains slag - solid waste from coal combustion, and granite screening, expanded clay, crushed stone... Such additives significantly reduce the cost of the material, but affect the bearing capacity: brick is used for the construction of buildings not higher than 3 floors.

There are other features as well. Cinder block is very hygroscopic... It cannot be used for the construction of the foundation, the walls themselves are allowed to be placed only on a high base - at least 70 cm. For the same reason, work is carried out only in dry weather, and immediately after construction, a protective coating must be applied to the walls.

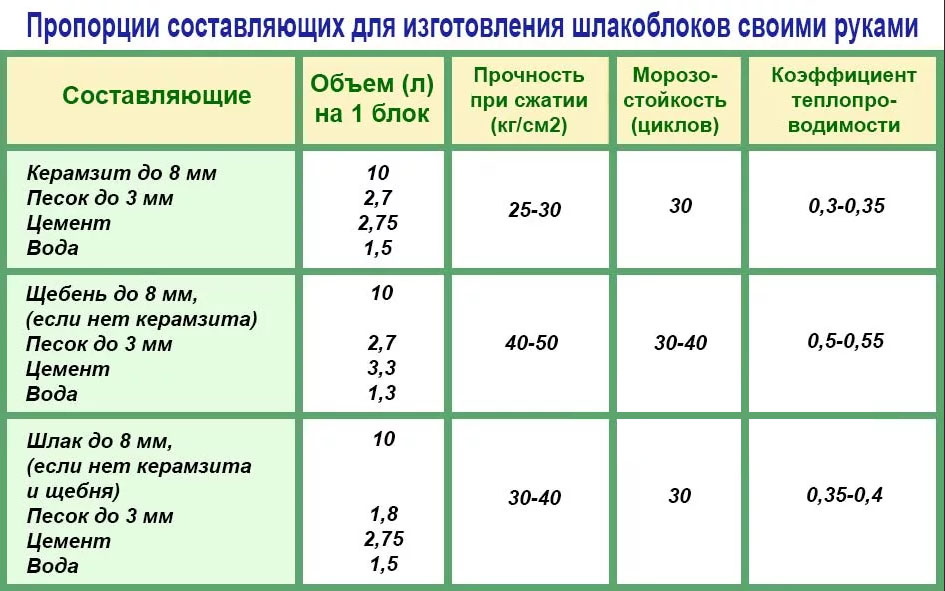

Production of cinder blocks: the initial products are mixed, poured into molds, placed on a vibrating table or vibrating machine. For a small building, cinder blocks can be made independently.

All characteristics of the cinder block are regulated by GOST.

Calculating the number of blocks

The calculation of the cinder block for the construction site begins with material selection:

- wall blocks with a width of 190 mm, a length of 391 mm and a height of 188 mm;

- partition - width is 90 mm, length and height are the same;

- facing - with the same dimensions, they are decorative and uniform in color.

It is important to choose degree of emptiness... In the lightest blocks, voids reach 40%. They are usually 2 round cavities. Heavier block with 4 narrow cavities or 7 slots. The heaviest is corpulent. It differs in maximum weight: with the same dimensions it weighs 19.5 kg versus 10.5 kg.

To calculate cinder blocks for construction, you need to take into account other factors:

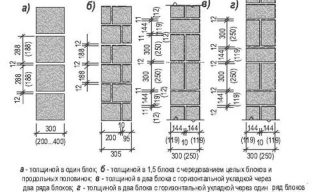

- block area in the wall, which depends on which side it is laid on;

- wall thickness - in 1, 1.5, in 2 rows;

- wall area - minus window and door openings.

Calculation procedure:

- define the parameters listed above;

- calculate the perimeter of the building;

- divide the perimeter by the block length to find out the number of bricks in a row;

- divide the wall height by the block height and calculate the number of rows;

- the total number of cinder blocks is found out by multiplying the number of pieces in a row and the number of rows.

The area of the window and door openings is subtracted from the result. The total is increased by 5-10%, to take into account the possible battle and damage to the stone when laying.

Sell cinder block in cubes. To find out how many blocks are in a cube and how many cubes are required for 1 square meter of a wall, you need to divide 1 cube. m. for the volume of one block. You can use the online calculator available on any construction site.

Choosing the type of masonry

- in 1 stone - traditional masonry suitable for most buildings;

- one and a half stones - this method is used if you want to improve thermal insulation;

- in 2 rows - the wall can withstand a higher load;

- spoon way - the brick is placed on spoons, and the thickness of the wall is half the stone. A method suitable for the construction of outbuildings and garages.

When laying, the usual dressing is performed. The displacement is calculated depending on the thickness of the wall, so the joint between the bricks of the previous row does not always appear in the center of the brick from the next row.

How to build walls from scratch

Before constructing a building, you must erect foundation and carefully waterproof it with roofing material or mastic... Prepare a mortar for masonry based on cement grade M-500 or M-400. For greater plasticity, red clay is added to the mixture. It is not recommended to use cinder block glue: the dimensions of the stones are not so accurate as to form a thin enough seam.

Step by step guide for the construction of walls includes the following steps.

- Lay on the surface of the foundation grout layer... It can be quite thick as, among other things, it evens out height differences.

- First of all, you need to lay corner blocks... They are connected with a cord or fishing line, along which all other bricks are installed. It is advisable to apply preliminary markings for the first row.

- An ordinary brick is held in the middle with one hand, neatly put in a row and align with the lace. Correct the position of the element with a trowel.

- Blocks slightly press down... Excess solution is immediately discarded. Make sure that the seam thickness does not exceed 1.5 cm. Line up the row over the lace.

- Next row start by laying half a brick from the corner to ensure the offset of the row.

The cement mortar is applied to the surface of the block and to 1 end.

Reinforcement of walls, how to attach a Mauerlat to cinder blocks

Laying the cinder block, if we are not talking about a very small box, involves reinforcement. Required the first row is strengthened, every 4th and last row before installing the roof or floor. Window and door openings are subject to reinforcement. Moreover, here the reinforcement is installed so that the rods come out on both sides of the opening by at least 30 cm.

When reinforcing the upper belt under the Mauerlat, you need to strengthen the walls under the slopes and along the gables.

Reinforcement is performed 3 ways.

- Laying in 1 or 2 rods - 1 or 2 grooves are cut on the surface of the row in the cinder block. Steel rods are laid in the grooves with an overlap of 20 cm and poured with cement mortar. Then continue laying in the usual way.

- Masonry mesh - with cells of 50 * 50 mm. The mesh is placed on the surface of the blocks and poured with a layer of mortar so that it completely covers it.

- Frame - 2 steel strips or rods are tied with a wire and in this form they are mounted on a layer of mortar or even glue. This method is resorted to if the house is exposed to additional loads: hurricanes are frequent in the area, the house is on a steep slope.