Plasterboard sheathing is very popular. The material is lightweight, non-flammable, quite resistant to water. It is easy to cut and bend when needed. As a rule, plasterboard sheets are attached to the frame. However, in many cases, you can do without it.

Bonding drywall to the wall

With relative evenness of the wall - with height differences of no more than 20 mm, drywall can be fixed directly to the surface, and not mount a crate under it. At the same time, sheets can fulfill their usual role: to mask the defects of the base wall and create a flat surface for wallpapering, painting and more.

The disadvantage of this solution is the lack of a gap. No air circulates between the sheathing and the wall... it is fraught with condensation between them and the destruction of the material, since only special waterproof drywall is resistant to constant dampness. The usual option is allowed when finishing dry rooms.

Technology features, pros and cons

There are 2 approaches: fixation on drywall glue or plaster... In the first case, glue is applied to one side of the material and pressed against the wall. In the second, the sheet is glued directly to the plaster.

Laying plasterboard sheets on plaster is used less often. The need for it arises if the gypsum board serves as the basis for heavy finishing.

Special plaster is often used - to improve sound insulation properties, for heat preservation.

Types of drywall glue

To work with gypsum plasterboard with their own hands, use adhesives 3 different categories... Preference is given to special mixtures, but there are many other options.

- Gypsum or mounting glue for gypsum plasterboard - the basis of the composition is gypsum. Additives of various kinds provide certain properties. For example, the mixture "Volma" includes plasticizers, so it is used for gluing not only gypsum board, but also foam, insulation. Elastic glue "Perlfix" contains synthetic fibers, which reduces material consumption.

- Silicone - this option is taken if drywall needs to be fixed to smooth or glossy surfaces. It can also be used when working with ordinary concrete or brick.

- Putty - the compositions are usually used for finishing surfaces, including gypsum board.It is important to choose a composition with high adhesive properties, for example, "Fugenfüller". The putty is applied pointwise, is used sparingly and prevents the appearance of fungi.

For fastening, you can also use the usual polyurethane foam, silicone or acrylic sealant, liquid nails.

Gypsum or polyurethane

The choice between the two options is difficult, since both materials are much more expensive than conventional dry assembly mixtures. This limits the scope of application. Most often they are used for ceiling cladding, pasting of arched surfaces.

Gypsum the composition is offered in the form of a thick viscous paste. The mixture is applied to the surface of the gypsum board in a continuous layer. A spatula is used: the glue layer has a raised surface, which ensures better adhesion.

You can use the gypsum composition only on clean, dry, relatively flat surfaces - with a height difference of 3 to 5 cm. In rooms with high humidity, gypsum glue is not used.

Moisture-resistant polyurethane adhesive, used for cladding kitchens and baths.

Description of the gluing process

The first way used when the wall is perfectly flat. The instruction is simple.

- Prepare the glue. 1 sheet requires about half a bucket.

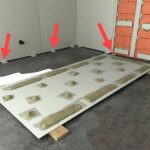

- Backing strips are placed on the floor opposite the installation site. GCR is laid on them face down.

- Stripes of the composition are applied to the sheet with a notched trowel. In places where the sheet will be attached over the wall defects, the layer is laid thicker. Raise the sheet and press it against the wall. Verticality is checked with a building level.

The glue can be duplicated with self-tapping screws.

Second way used if height differences exceed 5 cm... In this case, it is necessary to compensate for the most severe defects. For this, strips 10 cm wide and 12 cm long are cut from the gypsum board. The strips are glued in places where the walls have dents or recesses. You need to wait until the glue is completely dry.

Then a whole sheet of drywall is laid on the slats. On the seamy side, apply gypsum glue - "Perlfix", "Volma". Moreover, the glue is literally put in the form of piles, 5–6 cm high. The lump reaches its maximum height in those places where the dents and defects on the wall are the largest.

The GKL sheet is lifted, preferably together, and fixed on the wall. Do not press strongly: the glue is placed in such a way as to create a gap between the cladding and the wall. However, you need to level the sheet and smooth out the protruding areas.

Third method apply with very large irregularities... The technology is used the same as in method 2. But in order to achieve accurate alignment of the sheet, nails are first driven into the wall. They serve as beacons when attaching drywall.

The nature of the wall practically does not affect the choice of mounting adhesive for drywall. Universal gypsum mixtures are suitable for fixing on bricks, aerated concrete, plaster. Only if the gypsum board is placed on glossy surfaces, it is recommended to take silicone.

Consumption and storage conditions of glue

Material consumption and storage rules depend on the nature of the adhesive composition and are indicated on the package. In fact, the actual figures are somewhat different. "Perlfix" by Knauf hardens within 30 minutes so that it becomes impossible to use it. Therefore, all preliminary preparations - cutting, measuring, marking - must be done in advance.

The glue sets quickly. but complete drying occurs within 5-7 days... Therefore, it is advisable to postpone the staining, otherwise the sheets may shift during work.

The consumption of glue is 5 kg per 1 m². In reality, the consumption depends entirely on the installation method. When fastening in method 2, the composition will be consumed much faster. It is almost impossible to calculate the real consumption. Therefore, they usually buy several packages, and then calculate the required amount based on the results of pasting 1 wall.

How to make glue yourself

You can do the assembly glue yourself from plaster putty... To do this, a dry mixture is diluted in the calculated amount of water - a starting or finishing putty. Stir better with a construction mixer... You should get a homogeneous, fairly dense mixture without lumps. The consistency is approximately creamy.

Part add PVA glue and mix again until smooth. For 12-15 kg of adhesive, 1 kg of PVA is needed.

You need to cook small portionsbecause the glue hardens in 20-30 minutes.