Tongue blocks are actively used in the construction industry. Adhesive for tongue-and-groove slabs is a composition that is used to join them and form a monolithic seam without aesthetic defects. Popular manufacturers make gypsum-based glue, such compositions provide reliable adhesion to the structure.

Features of the glue for tongue-and-groove plates

The tongue-and-groove plates must be firmly fastened to each other.so that the design is reliable, retains its performance for a long period. In the process of connecting, it is better to use professional moisture resistant mixturesthat will withstand any temperature extremes.

Masters advise to choose glue of the same brand, as the tongue-and-groove blocks themselves, in order to avoid difficulties during the installation process.

It is forbidden to connect the plates to each other with plaster.

It is best to use the help of specialists during construction work if a person has not dealt with such adhesives.

Consumption of glue for GWP on average 1.5-2 kg one square meter. Packing weight 30 kg is enough for about 15 m², when it comes to the installation of single GWP.

Types of adhesives

Adhesive foam for GWP in terms of performance, there are two types: normal and frost-resistant... The first is used in apartments and private houses where there is heating, the air temperature does not reach critical levels. Frost-resistant glue is used to create partitions in industrial premises, warehouses, industrial halls. It contains special protective components that allow the plates to withstand frosts down to -15 degrees and not lose their strength properties at the same time.

Depending on the characteristics of the room in which the repair will take place, the glue may differ. There are two main types: based on gypsum and from sand and quicklime... Building mixtures are also classified moisture resistance.

Produce an adhesive foam that can be used to bond tongue-and-groove slabs, brick, stone.

The most popular brands that produce glue for GWP: Volma, Knauf, Bolars, IVSIL, ILLBRUCK.

Installation procedure

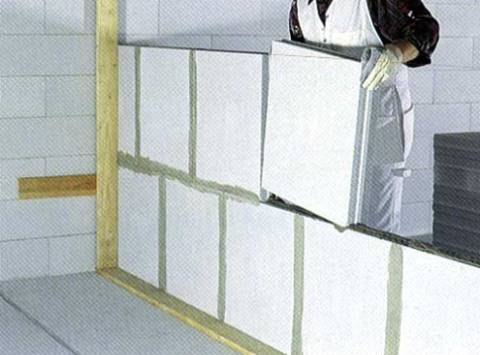

Installation is carried out in the following sequences:

- Clean the surface of the boards from dust and dirt, dry.

- To improve adhesion, the surface of the blocks can be primed.

- Wait for the primer to dry.

- Dilute the glue according to the instructions on the package.

- Apply the adhesive base with a spatula to the adjacent grooves of the tongue-and-groove blocks.

- Press the plates against each other for quick setting and the release of excess glue from the joint.

- Remove glue particles from the structure.

The optimum thickness of the joints between the blocks is 2 mm. After installing the structure, do not touch it for 30 minutes, until the adhesive base adheres. Work is best carried out in a warm room with an average humidity level.

How to work with dry mixes

The glue mixture is diluted in clean vessels... The water can be used warm or cold - it depends on the temperature in the room where the renovation is taking place. After diluting and mixing the composition, he needs let it brew for 30 minutes. As a result, you should get a thick, homogeneous mixture without lumps and bubbles.